USER GUIDE FOR PRESSURE SENSOR RS485-MODBUS RTU OUTPUT

|

JUN-2020 |

This document is applied for the following products

1. Pressure Sensor RS485-Modbus RTU Output

2. Specification

| Sensing Technology | Advanced PIEZO/Capacitance technology |

| Measuring range | Select from -1 .. + 35 bar Gage/Absolute/Sealed Gage |

| Over pressure protection | 1.5 x Span |

| Accuracy | 0.5% of span |

| Stability | < 0.3% span/year |

| Wetted parts | 304SS/316SS |

| Measuring Fluids | Any fluid which is workable with materials 304SS/316SS |

| Working temperature | -10 .. + 80 oC |

| Process connection | Standard G1/4 or Others (consult factory) |

| RS485 output | Default address: 1, baudrate: 9600, parity: none, data: 8 bit, stop bit: 1 |

| Power supply | 9..36VDC |

| Consumption | 5mA @ 12VDC supply |

3. Product Pictures

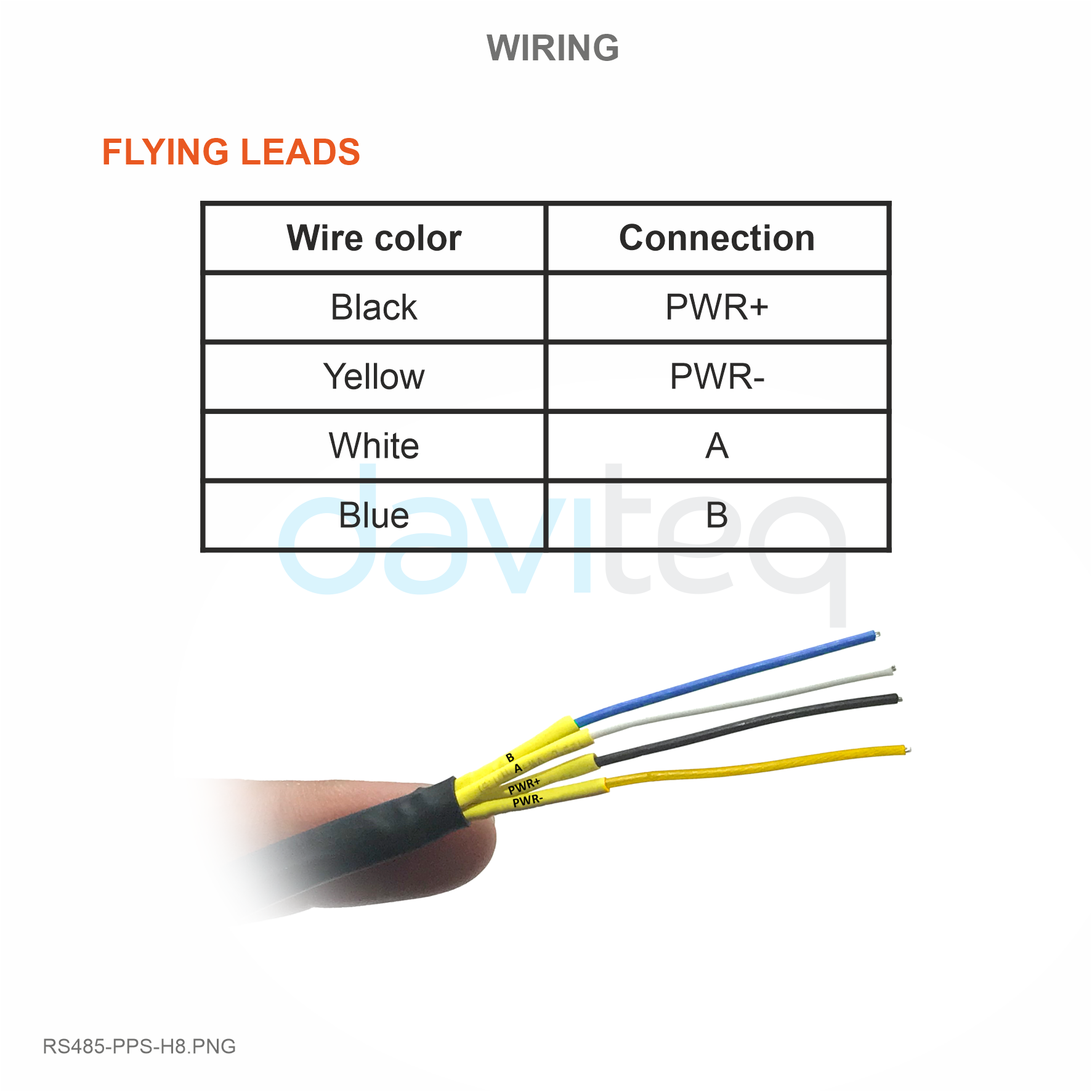

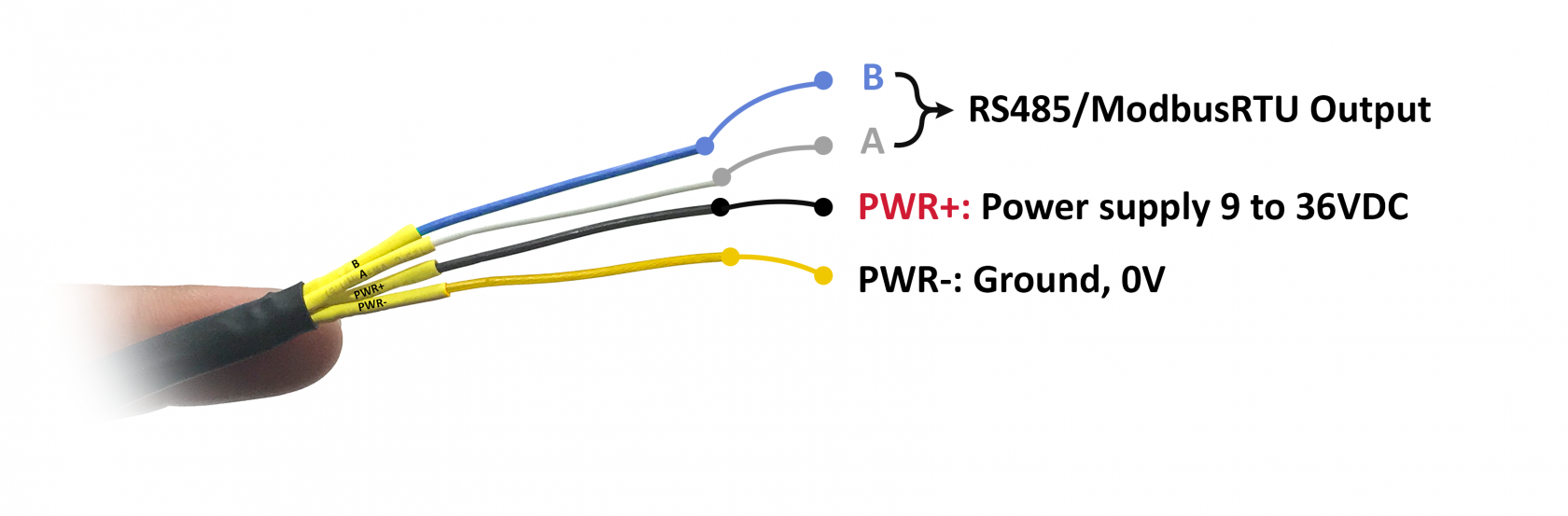

4. Wiring

Please wiring as shown below:

Memmap resgisters:

|

Modbus |

Modbus |

Function |

Function |

# of |

Range |

Default |

Format |

Property |

Comment |

|

0 |

0 |

3 |

|

2 |

|

|

string |

Read |

|

|

2 |

2 |

3 |

|

4 |

|

|

string |

Read |

|

|

6 |

6 |

3 |

|

2 |

|

|

string |

Read |

|

|

8 |

8 |

3 |

|

1 |

10, 30, 60, 99 |

|

uint16 |

Read |

Battery level, only 04 levels: 10%, 30%, 60% and 99% (full). When 10% ==> should replace the battery |

|

9 |

9 |

3 |

|

2 |

0..100% |

|

float |

Read |

Value from pressure process sensor. This value is parameter 1 of a wireless sensor node |

|

11 |

B |

3 |

|

1 |

|

|

uint16 |

Read |

Hi-Byte is error code, Lo-Byte is sensor type |

|

12 |

C |

3 |

|

2 |

|

|

float |

Read |

Value from pressure process sensor. This value is parameter 2 of a wireless sensor node |

|

14 |

E |

3 |

|

1 |

|

|

uint8 |

Read |

Hi-Byte is Logic status of parameter 1, Lo-Byte is Logic status of parameter 2 |

|

15 |

F |

3 |

|

2 |

|

|

uint32 |

Read |

Total time when Hi-Byte of Logic status = 1 |

|

17 |

11 |

3 |

|

2 |

|

|

uint32 |

Read |

Total time when Hi-Byte of Logic status = 0 |

|

19 |

13 |

3 |

|

2 |

|

|

uint32 |

Read |

Counter value when Hi-Byte of Logic status changes from 0 to 1 |

|

21 |

15 |

3 |

|

2 |

|

|

uint32 |

Read |

Counter value when Hi-Byte of Logic status changes from 1 to 0 |

|

23 |

17 |

3 |

|

2 |

|

|

uint32 |

Read |

Total time when Lo-Byte of Logic status = 1 |

|

25 |

19 |

3 |

|

2 |

|

|

uint32 |

Read |

Total time when Lo-Byte of Logic status = 0 |

|

27 |

1B |

3 |

|

2 |

|

|

uint32 |

Read |

Counter value when Lo-Byte of Logic status changes from 0 to 1 |

|

29 |

1D |

3 |

|

2 |

|

|

uint32 |

Read |

Counter value when Lo-Byte of Logic status changes from 1 to 0 |

|

256 |

100 |

3 |

16 |

1 |

1-247 |

1 |

uint16 |

Read/Write |

Modbus address of device |

|

257 |

101 |

3 |

16 |

1 |

0-1 |

0 |

uint16 |

Read/Write |

Baudrate: 0: 9600, 1: 19200 |

|

258 |

102 |

3 |

16 |

1 |

0-2 |

0 |

uint16 |

Read/Write |

Parity: 0: none, 1: odd, 2: even |

|

259 |

103 |

3 |

16 |

21 |

|

|

|

|

|

|

280 |

118 |

3 |

16 |

2 |

|

1 |

float |

Read/Write |

Scale value of parameter_1 = (a1 * Raw sensor value of parameter_1) + b1. For sensor value scale |

|

282 |

11A |

3 |

16 |

2 |

|

0 |

float |

Read/Write |

Scale value of parameter_1 = (a1 * Raw sensor value of parameter_1) + b1. For sensor value scale |

|

284 |

11C |

3 |

16 |

2 |

|

1 |

float |

Read/Write |

Scale value of parameter_2 = (a2 * Raw sensor value of parameter_2) + b2. For sensor value scale |

|

286 |

11E |

3 |

16 |

2 |

|

0 |

float |

Read/Write |

Scale value of parameter_2 = (a2 * Raw sensor value of parameter_2) + b2. For sensor value scale |

|

288 |

120 |

3 |

16 |

2 |

|

|

float |

Read/Write |

|

|

290 |

122 |

3 |

16 |

2 |

|

|

float |

Read/Write |

High threshold value for parameter 1 |

|

292 |

124 |

3 |

16 |

2 |

|

|

float |

Read/Write |

Low threshold value for parameter 1 |

|

294 |

126 |

3 |

16 |

2 |

|

|

float |

Read/Write |

High threshold value for parameter 2 |

|

296 |

128 |

3 |

16 |

2 |

|

|

float |

Read/Write |

Low threshold value for parameter 2 |

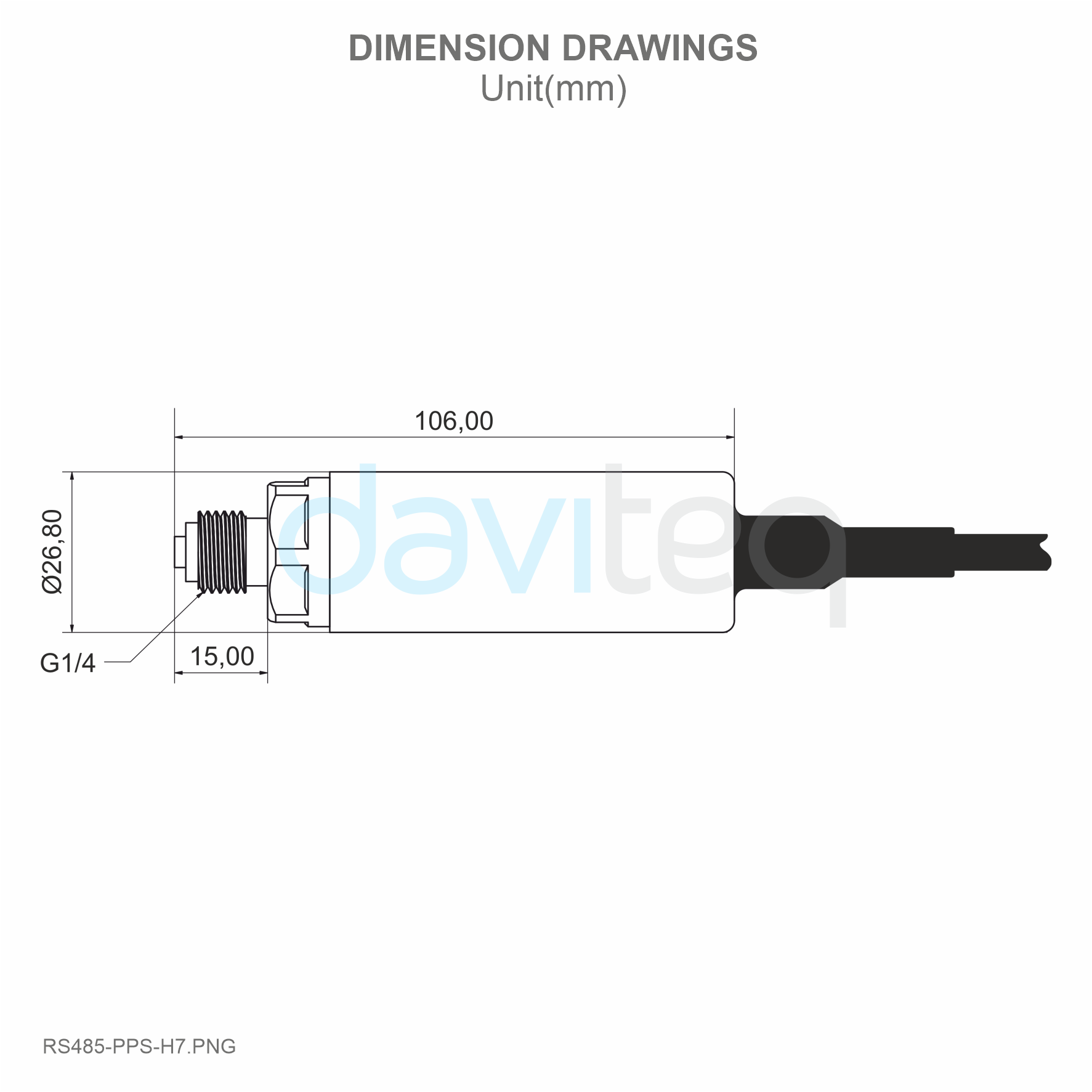

5. Dimensions

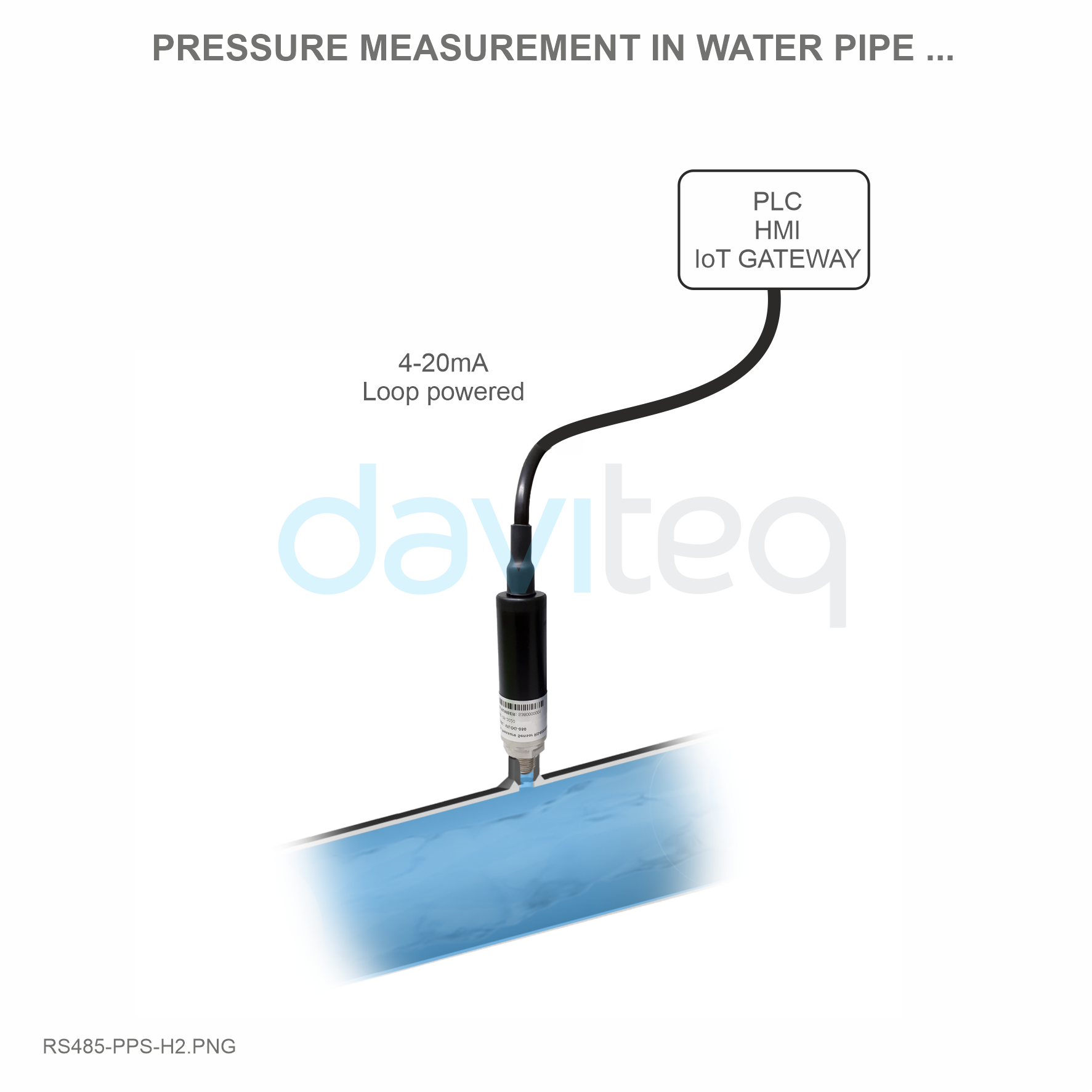

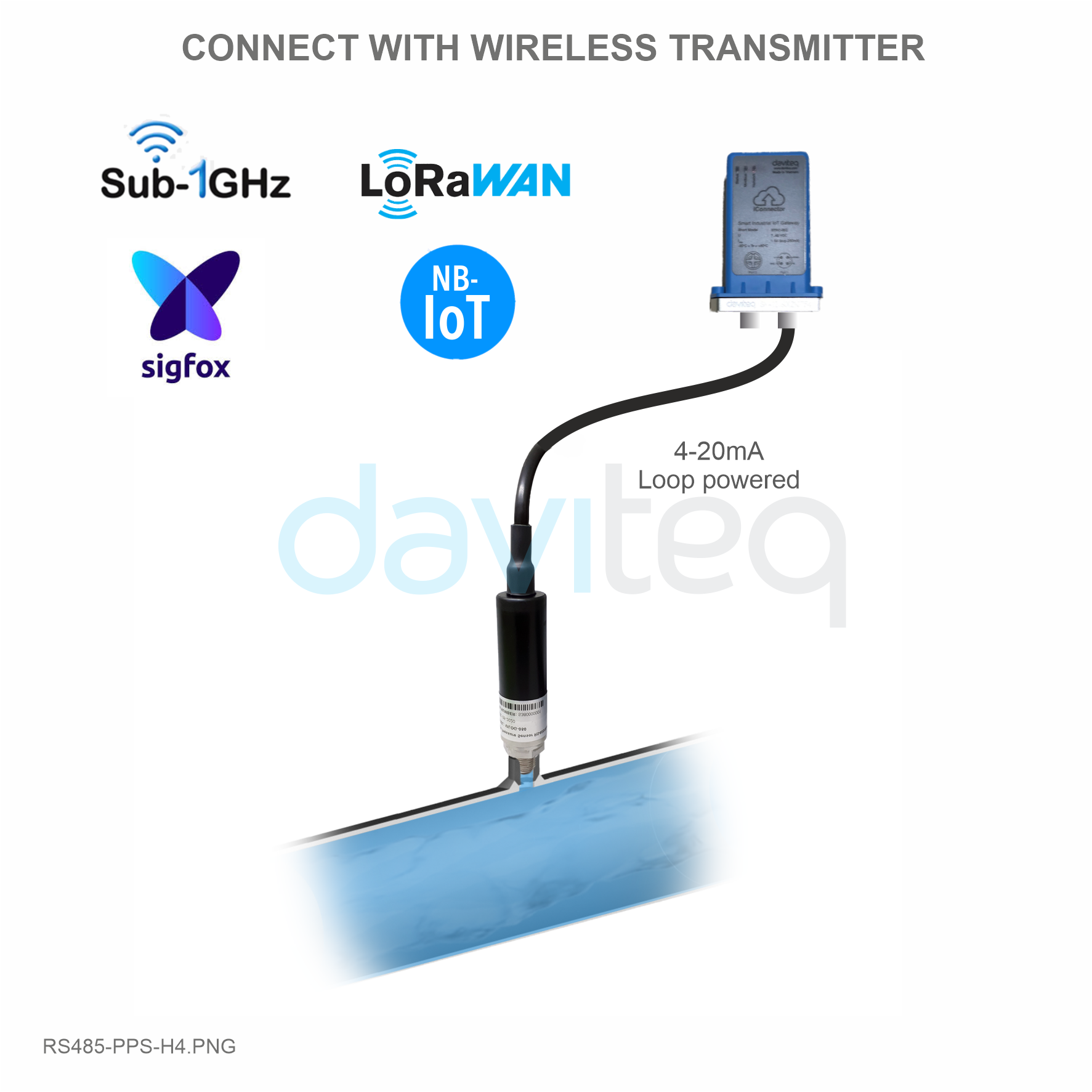

6. Applications

|

|

|

|

7. Support contacts

|

Manufacturer Daviteq Technologies Inc No.11 Street 2G, Nam Hung Vuong Res., An Lac Ward, Binh Tan Dist., Ho Chi Minh City, Vietnam. Email: info@daviteq.com | www.daviteq.com |

No Comments