USER GUIDE FOR PROCESS FLAT ORP SENSOR WITH MODBUS OUTPUT MBRTU-ORPFLAT

|

JUL-2021 |

This document is applied for the following products

1. Introduction

MBRTU-ORPFLAT is a general purpose in-line (continuous measurement) ORP sensor offering affordable, flat sensor application coverage for many water applications such as drinking water, industrial water, aquaculture, tank installations or related applications. The flat surface sensor is often referred to as "self-cleaning" when installed in a process stream since the water flow has a tendency to "shear off" biofouling and other debris from the sensor surface. Output is Modbus RTU for easily integrating with any PLC, controller, SCADA, BMS or IoT gateway.

- Robust ORP electrode for continuous measurement;

- Self-cleaning flat electrode;

- Standard ModbusRTU output;

- Plug & Play

Typical Applications: Common applications include disinfection using chlorine, ozone, and bromine. All of these species are strong oxidizers, so ORP is used as an indicator of sanitizing activity. ORP is also used in process applications to monitor destruction of chromate or cyanide, as well as in bleach production and wet scrubbers.

2. Specification

| ORP SENSOR SPECIFICATION | |

| Sensing Technology | Glass, combine electrode |

| Measuring range | +/- 2000 mV |

| Resolution | 0.1 mV |

| Accuracy | +/- 1 mV |

| Working temperature | 0 .. 100 oC (compensated) |

| Working pressure | 0 .. 100 psig |

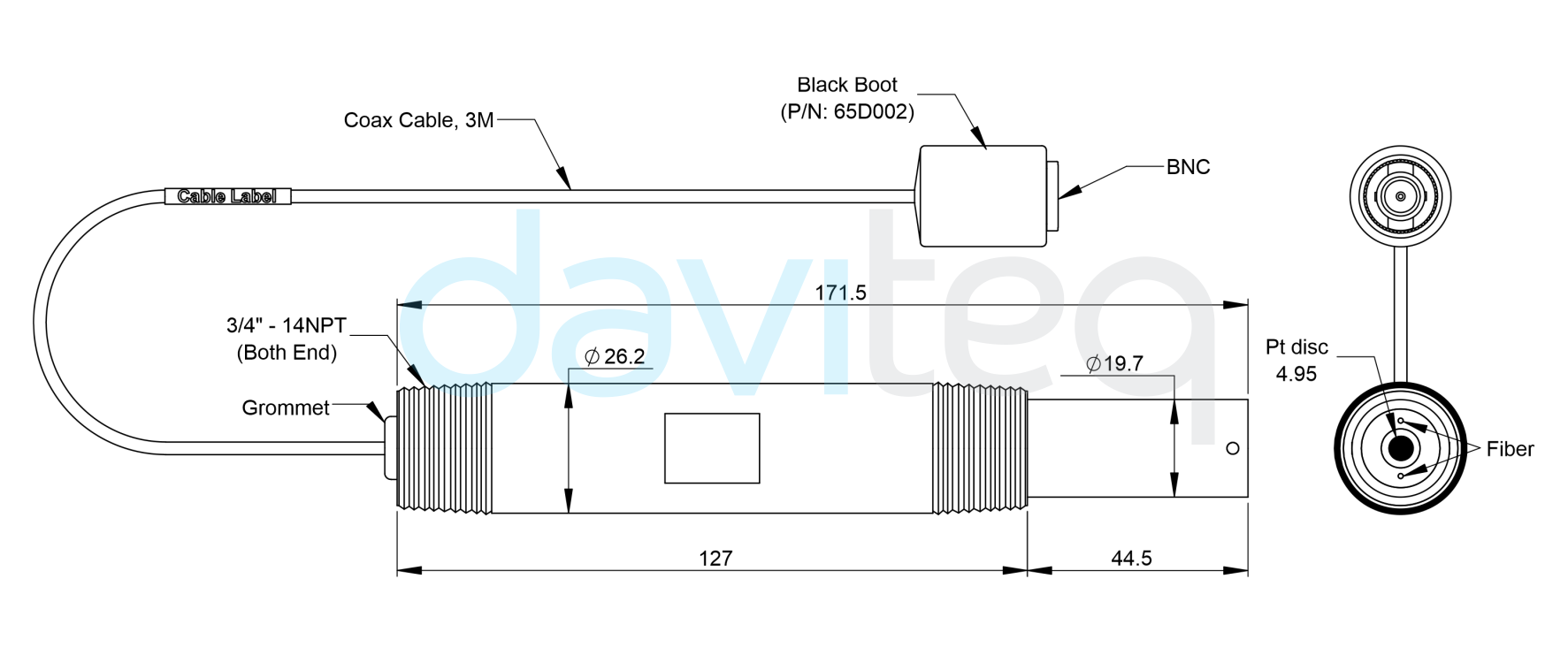

| Process connection | 3/4" NPT both ends |

| Wetted parts | PVC |

| Sensor Cable | 6m with BNC connector |

| Rating | IP68 |

| Sensor Dimension | D27 x 172 (mm) |

| Sensor net weight | < 200 grams |

| ORP TRANSMITTER SPECIFICATION | |

| Inputs | mV |

| Output | RS485, ModbusRTU protocol, max 19200 baud |

| Power supply | 9..36VDC, avg. < 200mA |

| Mounting | DIN Rail |

| Working temperature | -40 .. 85 oC |

| Working humidity | 0 .. 95% RH, non-condensing |

| Housing | Engineered Plastic |

| Ingress Protection | IP20 |

| Dimension | 93 x 40 (mm) |

| Net weight | <200 grams |

3. Dimensions

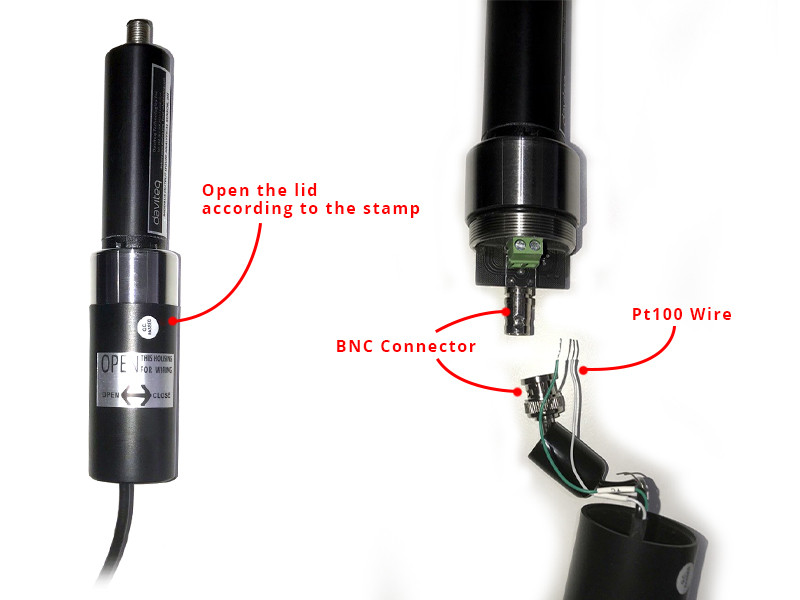

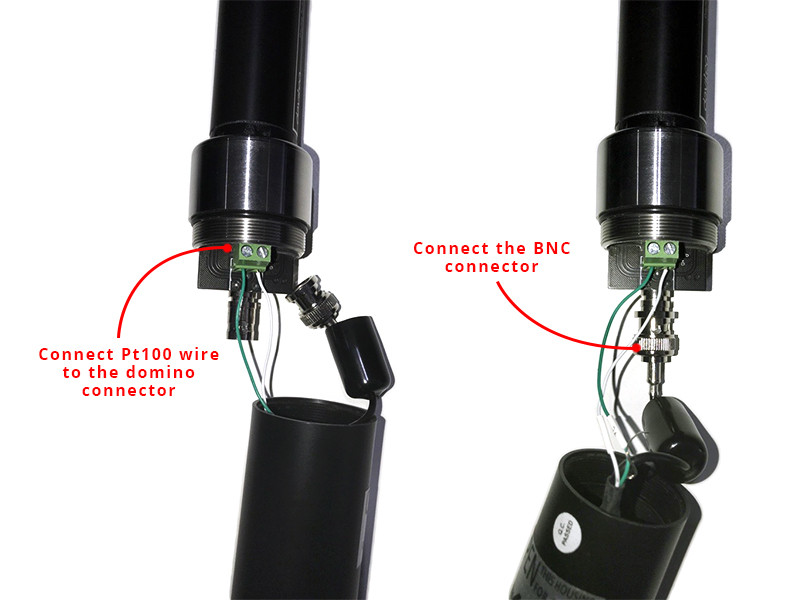

4. Wiring

Please wiring as shown below:

|

|

|

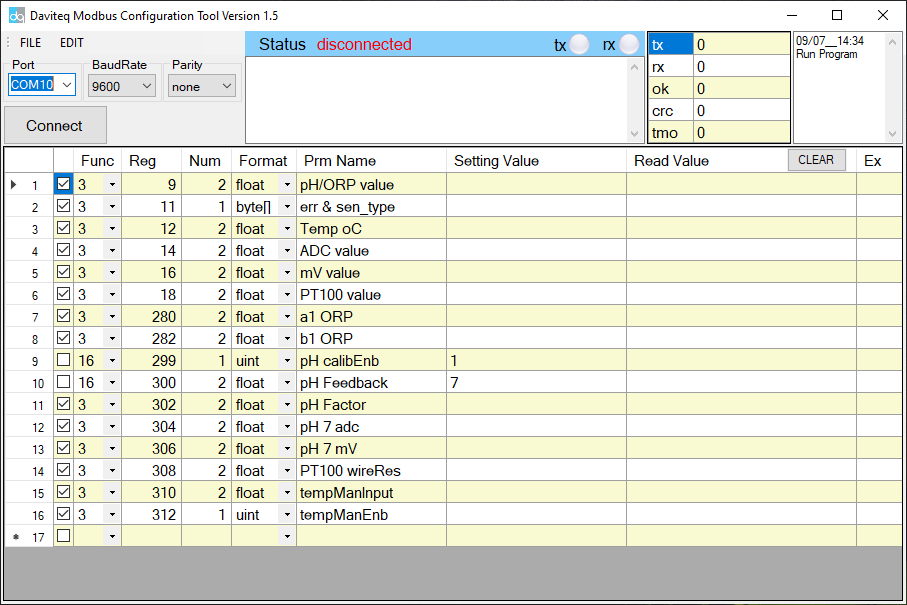

5. Memmap registers

- Function Code: 3 (Read); 16 (Write)

|

Functio Code |

Modbus Register (Decimal) | # of Registers |

Format Type |

Parameter Name |

Setting Value |

Format

|

Note |

| 3 | 9 | 2 | float | pH/ORP value | Read | pH/Orp value measured from sensor | |

| 3 | 11 | 1 | byte[] | err & sen_type | Read | Hi-Byte is error code, Lo-Byte is sensor type | |

| 3 | 12 | 2 | float | Temp ℃ | Read | ||

| 3 | 14 | 2 | float | ADC value | Read | ||

| 3 | 16 | 2 | float | mV value | Read | ||

| 3 | 18 | 2 | float | PT100 value | Read | ||

| 3 | 256 | 1 | uint16 | Modbus address | 1 | Read / Write | Modbus address of device |

| 3 | 257 | 1 | uint16 | Modbus baudrate | 0 | Read / Write | Baudrate: 0: 9600, 1: 19200 |

| 3 | 258 | 1 | uint16 | Modbus parity | 0 | Read / Write | Parity: 0: none, 1: odd, 2: even |

| 3 | 280 | 2 | float | a1 ORP | Read / Write | Scale value of parameter_1 = (a1 * Raw sensor value of parameter_1) + b1 | |

| 3 | 282 | 2 | float | b1 ORP | Read / Write | Scale value of parameter_1 = (a1 * Raw sensor value of parameter_1) + b1 | |

| 16 | 299 | 1 | uint | pH calibEnb | 1 | Read / Write | |

| 16 | 300 | 2 | float | pH Feedback | 7 | Read / Write | |

| 3 | 302 | 2 | float | pH Factor | Read / Write | ||

| 3 | 304 | 2 | float | pH 7 adc | Read / Write | ||

| 3 | 306 | 2 | float | pH 7 mV | Read / Write | ||

| 3 | 308 | 2 | float | PT100 wireRes | Read / Write | Offset resistor wires | |

| 3 | 310 | 2 | float | tempManInput | Read / Write | ||

| 3 | 312 | 1 | uint | tempManEnb | Read / Write |

6. Required Equipment and Solutions

- pH/mV meter

- pH buffer 4.01 saturated with Quinhydrone (Solution has 2 – 4 use life after mixing)

- pH buffer 7.00 saturated with Quinhydrone (Solution has 2 – 4 use life after mixing)

- Wash bottle filled with distilled or de-ionized water

- Lab wipes

- Laboratory magnetic stirrer and magnetic stir bars

- Clean beakers

7. Preparation of the Electrode for Initial Use

Mono ORP electrodes are shipped dry with a rubber boot covering the tip of the electrode to protect the sensing element.

Combination ORP electrodes are shipped with a storage bottle with storage solution. Keep the solution bottle and solution for future use.

Remove the bottle or the boot from the electrode and thoroughly rinse the electrode tip with distilled water. Wipe carefully with a clean lab wipe.

For refillable combination ORP models, uncover the filling port to expose the electrode reference chamber fill hole (for sealed, gel filled electrodes, disregard this operation). Fill the reference chamber with reference filling solution. Use the appropriate reference filling solution. Electrodes that have been filled with the incorrect filling solution are not covered under warranty.

8. Reference Filling Solution Selection

- For ORP combination electrodes with Calomel and Double Junction Ag/AgCI reference half cells, use 4 M KCI reference filling solution.

- For ORP combination electrodes with Single Junction Ag/AgCI reference half cells, use 4 M KCI saturated with AgCI reference filling solution.

9. Calibration

Before use, the instrument should be calibrated with standard solutions;

The first is calibration with standard solution ORP 240mV. Buy standard solutions here:

The next step is to calibrate with standard solution ORP 470mV. Buy standard solutions here:

Note the ambient temperature at the time of calibration to input the standard mV value according to the temperature (indicated on the body of the standard bottle)

Use any modbus master tool to calibrate the sensor. Or use Daviteq's Modbus software, along with a configuration cable...

How to use Modbus Configuration Tool (Click Here)

Step 1: Import the Template file into Modbus Configuration Tool

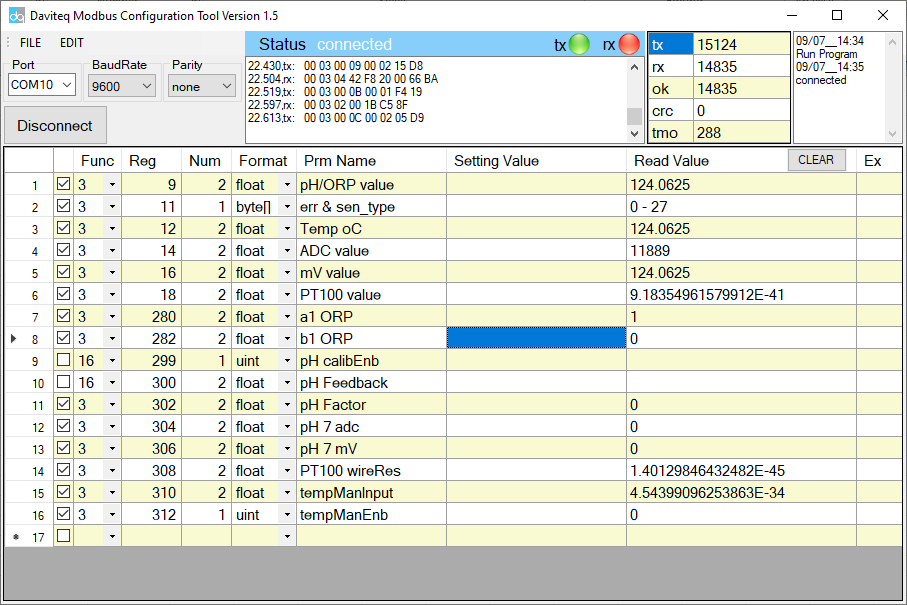

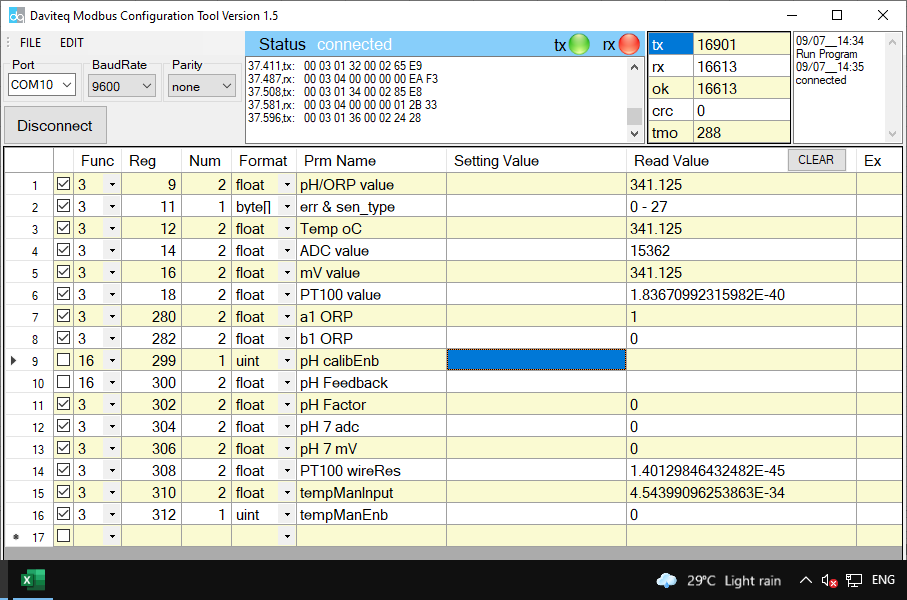

Step 2: Put ORP sensor to standard ORP 240mV and record mV value

Step 3: Remove the electrode from the buffer. Rinse with distilled water and blot with a lab wipe then put to Standard ORP 470mV and record mV value

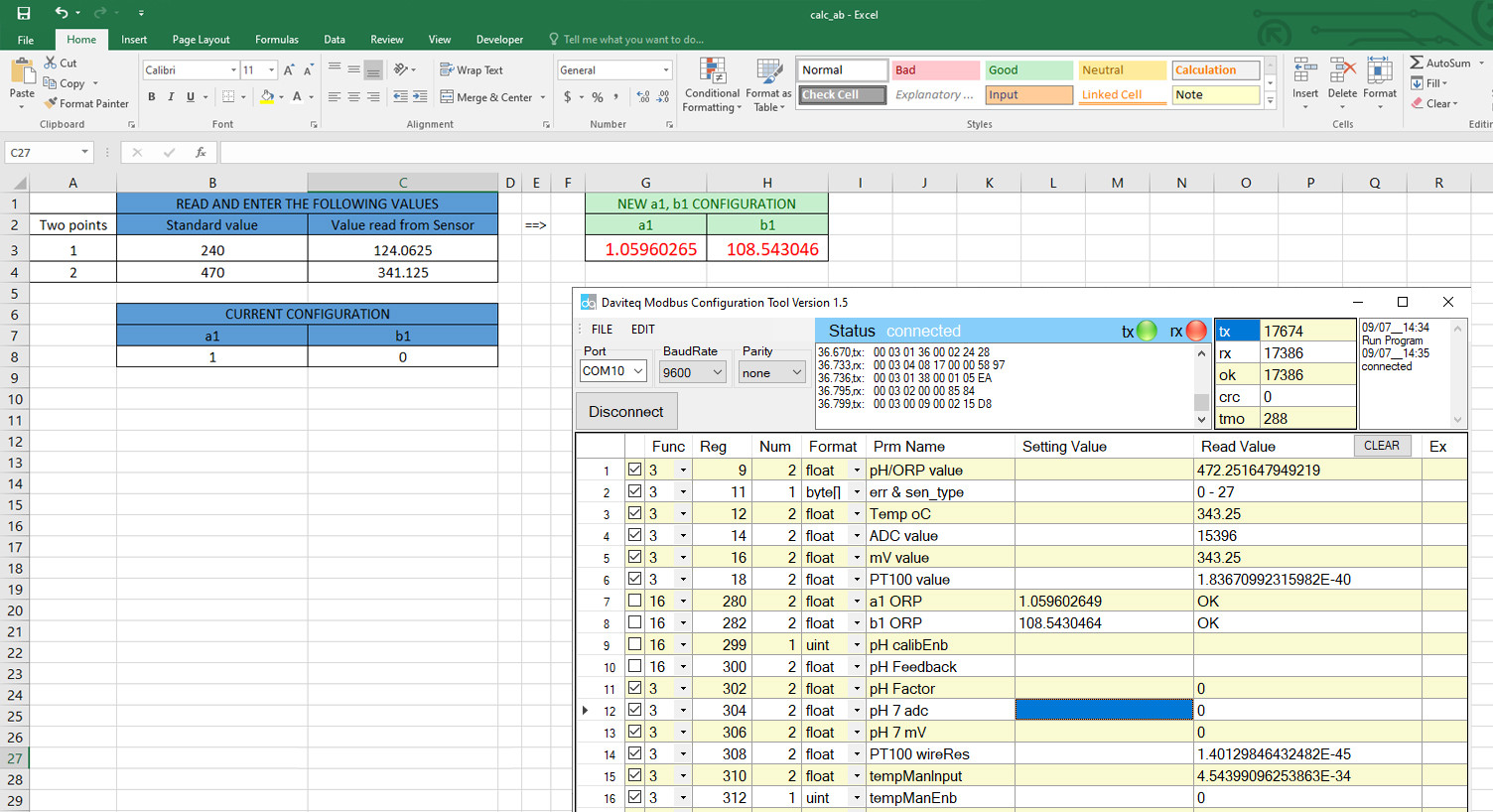

Step 4: Calculate a1 and b1 value for ORP by excel file then write them to Reg 280 and 282 by check in the box to run func 16.

Caculate a1 and b1 excel file: lhttps://filerun.daviteq.com/wl/?id=qTEXAavKl1dSbnkbUgSAQXdK2jEtr1qA

10. Reading a Sample with the Electrode

- Rinse the electrode with distilled water and blot with a lab wipe. Place the electrode in a beaker containing the sample and a stir bar. Stir as before. Record the mV reading when the reading is stable.

- Remove the electrode from the sample, rinse the electrode with distilled water over the "waste" beaker. Blot the electrode dry with a lab wipe. The electrode is now ready to read the ORP readings of other samples.

11. Storing the Electrode

Mono ORP electrodes should be stored clean and dry. Combination ORP electrodes should always remain immersed in storage solution. When storing for long periods, store the electrode in the storage bottle or boot which came with the electrode.

12. Electrode Cleaning

Contamination of the sensing element often results in slow response and inaccurate readings. Clean the element by one of the following procedures:

- Inorganic Deposits: Immerse electrode tip in 0.1 N HC1 for 10 minutes. Wash the tip with distilled water.

- Organic Oil and Grease Films: Wash electrode tip in a liquid detergent and water.

- After above treatment, soak the electrode tip in alcohol for 5 minutes and wipe dry, then, soak in quinhydrone saturated pH 4.01 for 15 minutes; rinse with distilled water afterwards.

NOTE: DO NOT ATTEMPT TO SAND OR POLISH THE SENSING ELEMENT WITH SAND PAPER OR OTHER POLISHING MATERIAL!

13. Contact

|

Manufacturer Daviteq Technologies Inc No.11 Street 2G, Nam Hung Vuong Res., An Lac Ward, Binh Tan Dist., Ho Chi Minh City, Vietnam. Email: info@daviteq.com | www.daviteq.com |

No Comments