USER GUIDE FOR WIRELESS PIEZO-ELECTRIC 10KHZ VIBRATION SENSOR WS433-V1A

| WS433-V1A-MN-EN-01 |

APR-2021 |

This document is applied for the following products

|

SKU |

WS433-V1A |

HW Ver. |

2.5 |

FW Ver. |

5.0 |

|

Item Code |

WS433-V1A-01 |

Wireless Piezo-electric 10Khz Vibration Sensor, 433Mhz, +/-50g, pre-calibrated, AA 1.5-3.6VDC battery, IP67 |

|||

1. Functions Change Log

| HW Ver. | FW Ver. | Release Date | Functions Change |

| 2.5 | 5.0 | DEC-2019 |

|

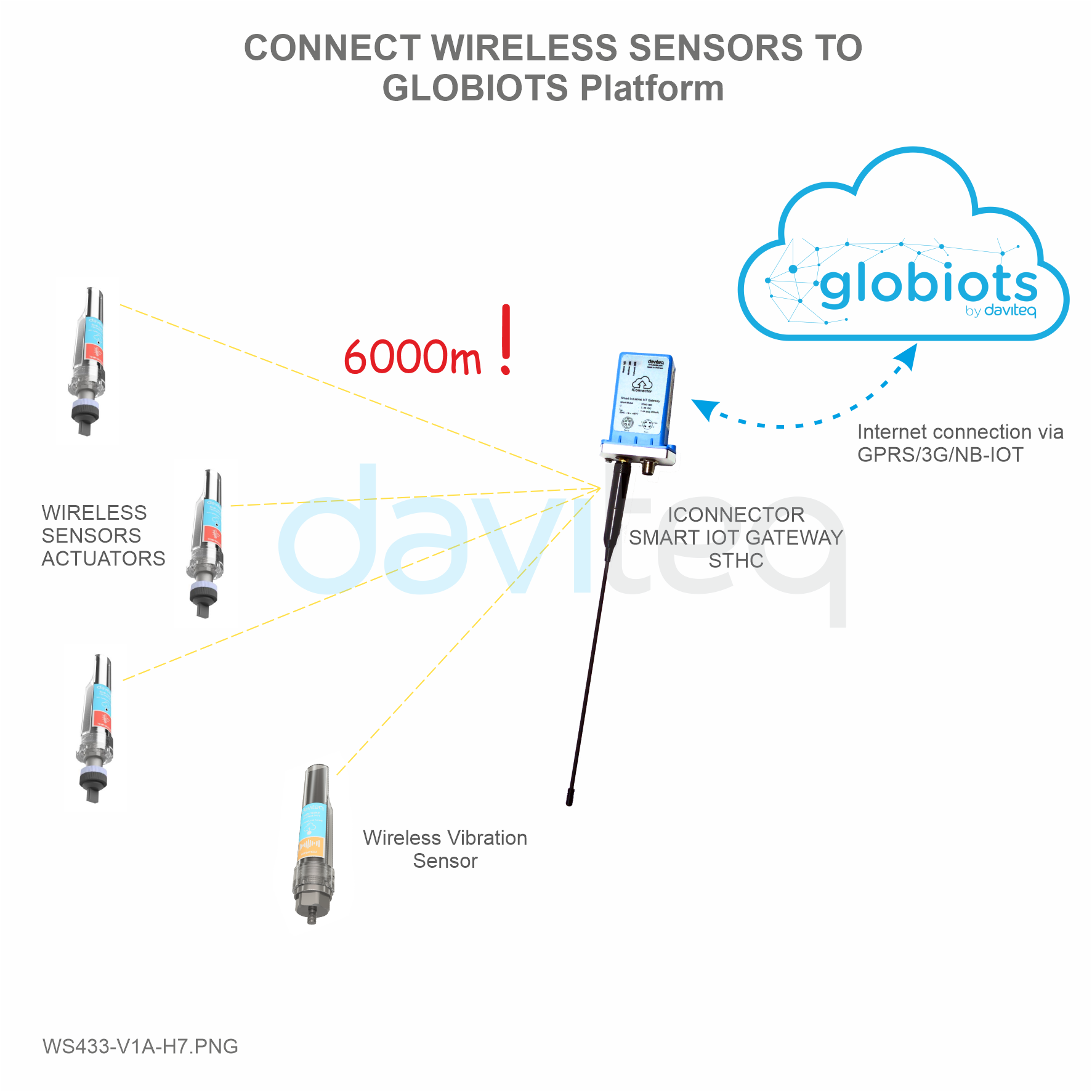

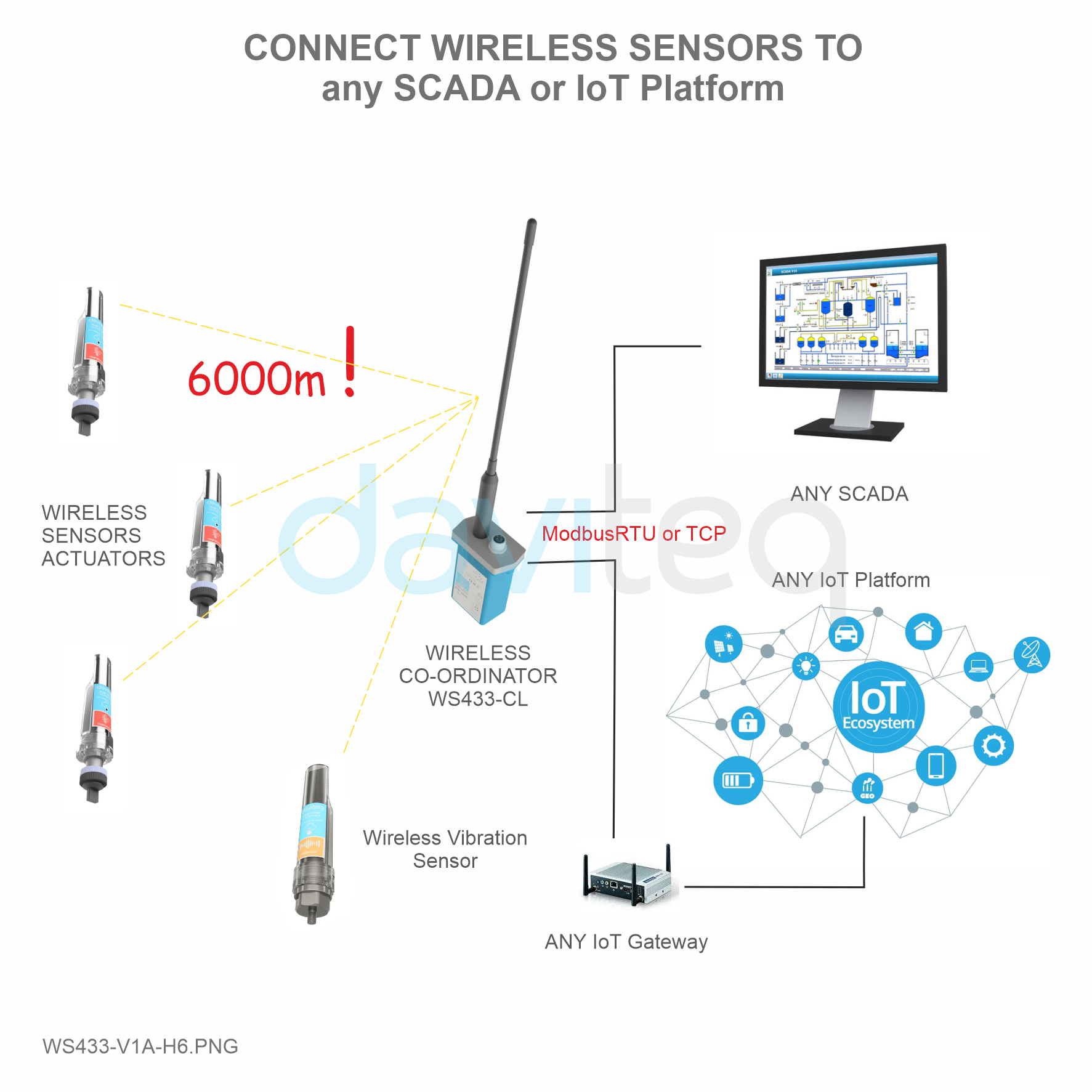

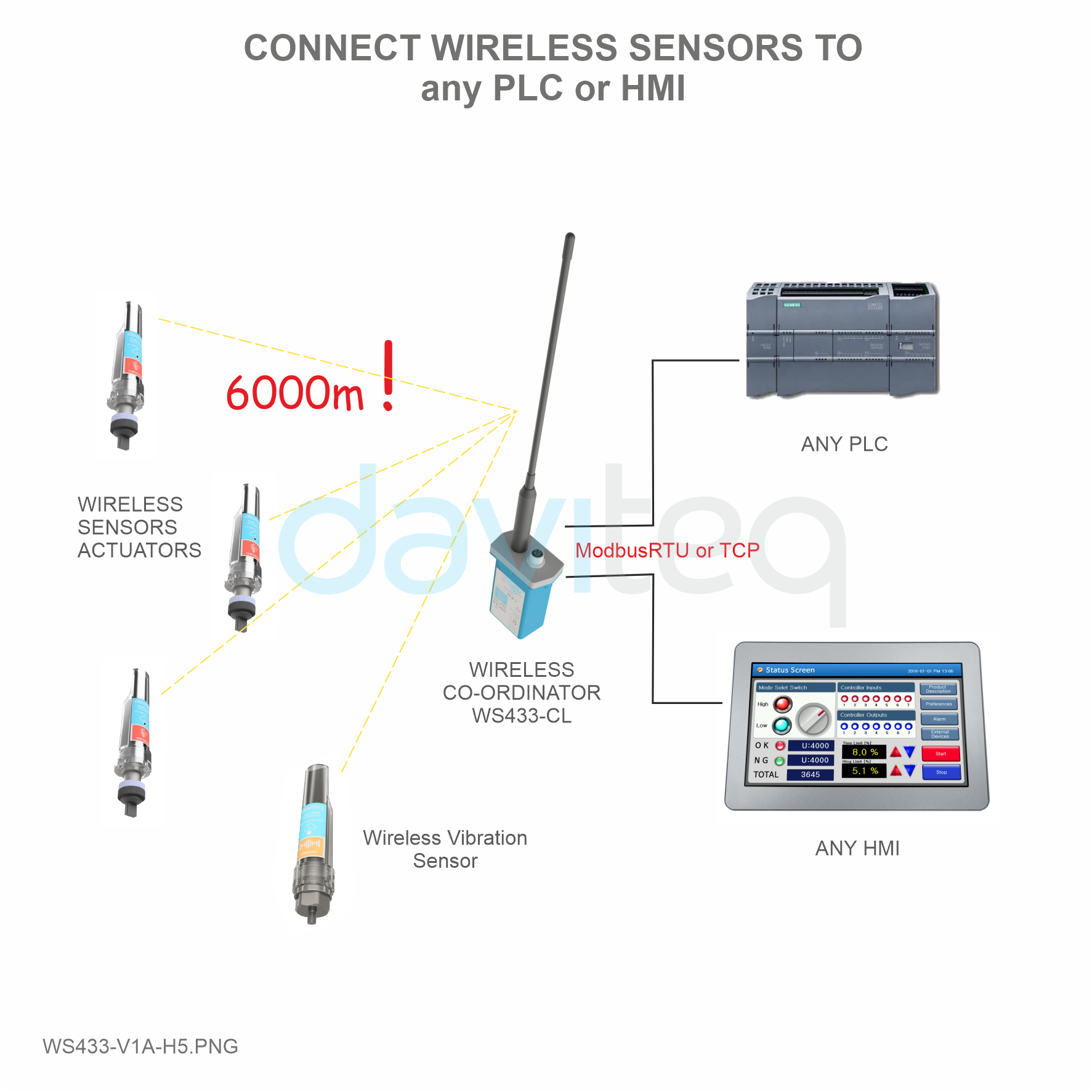

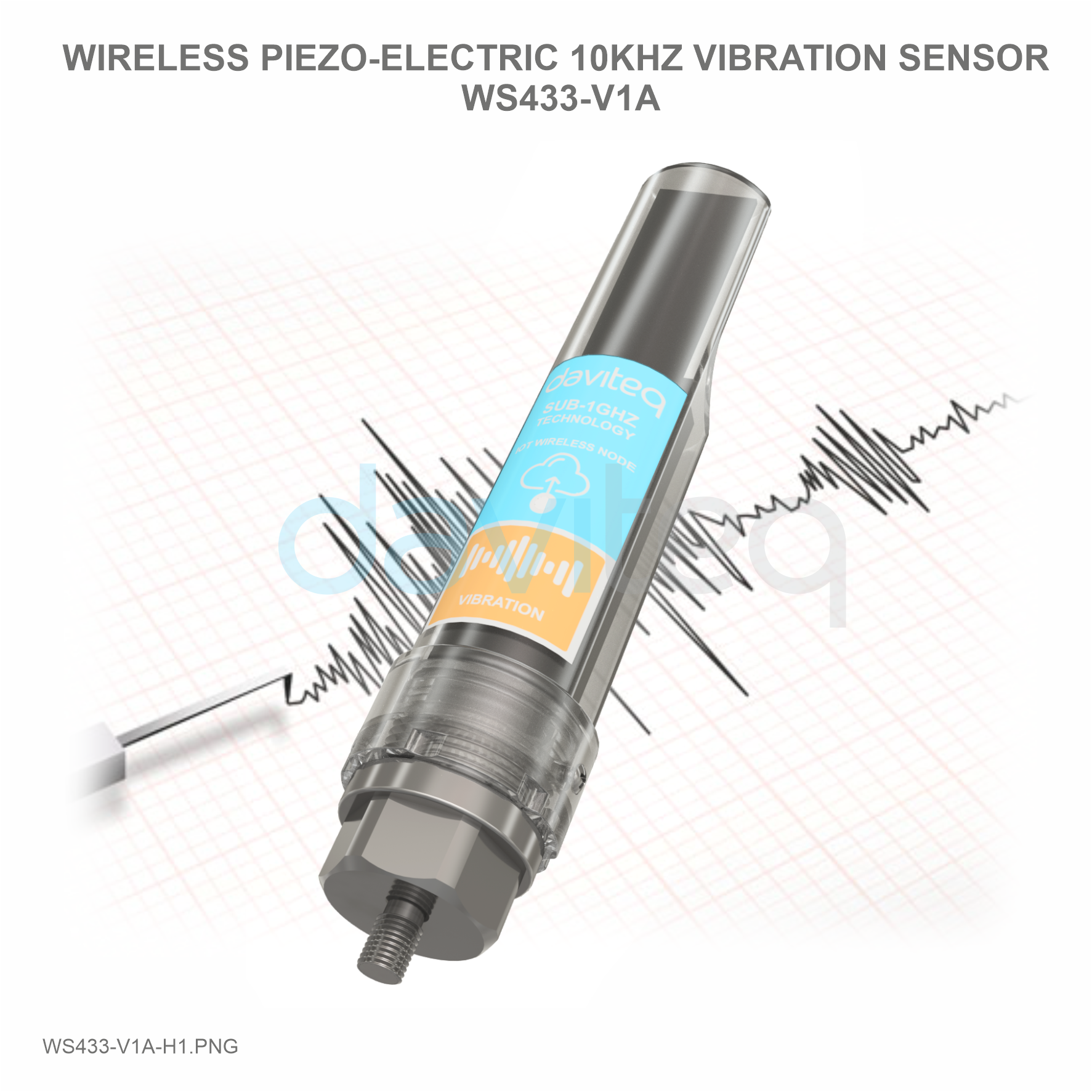

2. Introduction

WS433-V1A is a cost effective, wireless accelerometer single-axis vibration sensor designed for condition monitoring and preventive maintenance applications. The piezo-electric accelerometer is available in ranges ±50g and features a flat frequency response up to >10kHz. Its accelerometer feature a stable piezo-ceramic crystal in shear mode with low power electronics, sealed in a fully hermetic package. The Piezo Electric technology incorporated in the WS433-V1A accelerometer has a proven track record for offering the reliable and long-term stable output required for condition monitoring applications. The accelerometer is designed and qualified for machine health monitoring and has superior Resolution, Dynamic Range and Bandwidth to MEMS devices. Beside that it can also measure the temperature at mounting point. The sensor will connect wirelessly to the Wireless Coordinator WS433-CL then export the data to RS485 / modbusRTU and from there easily connect to any monitoring and control system. LOS distance from sensor to receiver is 1000m and can be extended by Extender. Typical applications include: Machine Health Monitoring, Predictive Maintenance Installations, Vibration Monitoring, Impact & Shock Monitoring, Bearing monitoring...

3. Specification

| VIBRATION SENSOR SPECIFICATION: | |

| Sensor type | Hermetically Sealed, Piezo-Ceramic Crystal, Shear Mode |

| Acceleration Range and Shock Limit (g) | ±50, 10,000 |

| Frequency Response and Resonant Frequency (Hz) | 2-10000, >30000 |

| Non-Linearity, Transverse Sensitivity | ±2%FSO, < 5% |

| Temperature measuring and operating range, accuracy & resolution (°C) | -40.. +85, +/- 0.5, 0.125 |

| Sensor Material, mousing protection and mounting | 304SUS, IP67, M6 Screw |

| *Notes | All above values are typical at +24°C, 80Hz |

| WIRELESS SPECIFCATION: | |

| Data speed | Up to 50kbps |

| Tranmission distance, LOS | 1000m, internal Antenna |

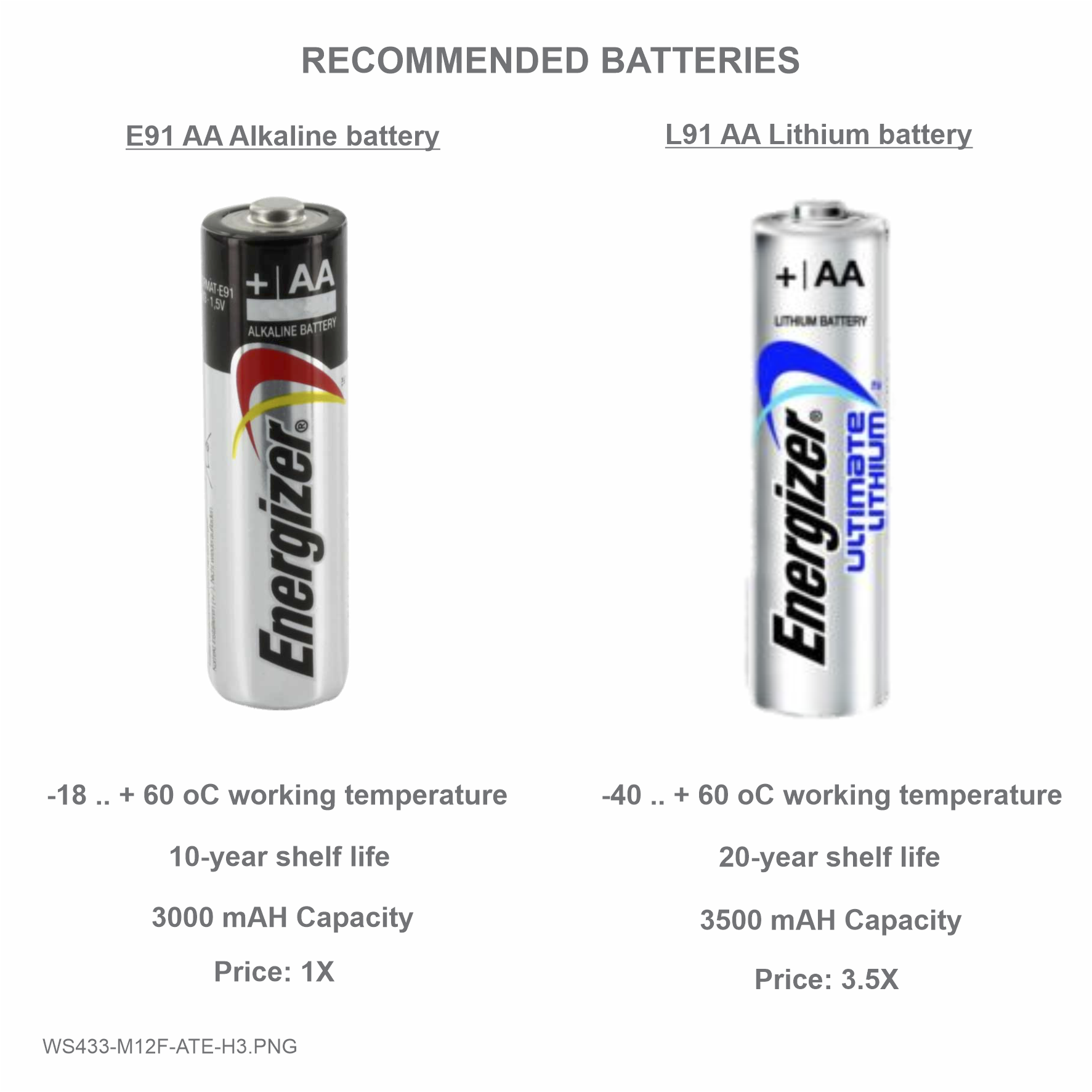

| Battery | 01 x AA 1.5-3.6VDC, up to 10-year operation, depends on configuration |

| Frequency Band | ISM 433Mhz, Sub-GHz technology from Texas Instrument, USA |

| International Compliance | ETSI EN 300 220, EN 303 204 (Europe) FCC CFR47 Part15 (US), ARIB STD-T108 (Japan) |

| Vietnam Type Approval Certification | QCVN 73:2013/BTTTT, QCVN 96:2015/BTTTT (DAVITEQ B00122019) |

| Security Standard | AES-128 |

| Operating temperature of PCB | -40oC..+60oC (with AA L91 Energizer) |

| Housing | Poly-carbonate, IP67 |

| Installation method | Integrated with Sensor |

| Product dimensions & weight | 150x30x30mm, < 260g (without battery), with sensor |

| Box dimension & gross weight | 190x50x50mm, < 300g |

4. Typical Applications

|

|

|

|

5. Operation Principle

5.1 Process of measurement

When the sensor sampling time interval is reached, For example 2 minutes, the node will wake up and switch ON the power supply to supply the energy to external sensor to start the measurement. Depends on the type and characteristic of external sensor, the sensor will take a certain time to finish the measurement.

For example: the measurement time is 200mS, after this time, the node will read the value of sensor, node will switch OFF power supply to external sensor to save energy.

The measured value is the raw value of the sensor. The measured value can be scaled according to the following formula:

Y = aX + b

-

-

-

-

- X: the raw value from the sensor

- Y: the calculated value for parameter 1's value or parameter 2's value

- a: constant (default value is 1)

- b: constant (default value is 0)

-

-

-

So, if there is no user setting for a and b ==> Y = X

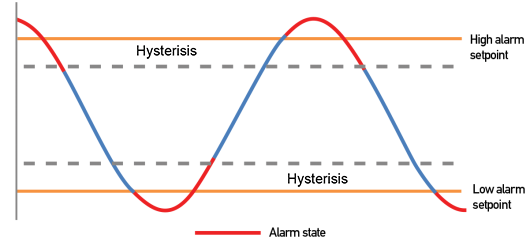

The Y value will be compared with Lo and Hi threshold. Please refer below the graph of alarm processing.

Status bytes of sensor Node

- Hi-Byte is error code

| Error code | Description |

| 0 | No error |

| 1 | Just exchange the sensor module but node has not been reset ==> please take out the battery for 20s then install it again to reset node to recognize the new sensor module |

| 2 | Error, sensor port M12F shorted to GND |

| 3 | Error, sensor port M12F shorted to Vcc |

| 4 | Error, sensor port M12F shorted each other |

- Lo-Byte is sensor type

| Error code | Description |

| 0 | No error |

| 1 | Just exchange the sensor module but node has not been reset ==> please take out the battery for 20s then install it again to reset node to recognize the new sensor module |

| 2 | Error, sensor port M12F shorted to GND |

| 3 | Error, sensor port M12F shorted to Vcc |

| 4 | Error, sensor port M12F shorted each other |

5.2 Add sensors node to Co-ordinator WS433-CL

5.2.1 Add Sensor Node ID automatically

|

|

Step 1: After supplying power the Co-ordinator via M12 connector, the Node ID must be registered within the first 5 minutes, up to 40 WS.

Step 2: Bring the wireless sensor closer to the Co-ordinator's antenna then take off the wireless sensor battery, wait for 5s then insert the battery again. If:

- Buzzer plays 1 peep sound, LED blink 1 time, that means registering Node ID on Co-ordinator successfully.

- Buzzer plays 2 peep sounds, LED blink 2 times, that this Node ID is already registered.

If you do not hear the "Peep" sound, please disconnect the power the co-ordinator, wait a few minute and try again.

Node id added in this way will be written to the smallest node_id_n address which is = 0.

Set Rssi_threshold (see RF MODE CONFIG (in the Modbus Memmap of WS433-CL), default -25): The case if Co-ordinator is on high position and need to add node sensor. We set the sensor as close as possible and set the Rssi_threshold to -80, -90 or -100 to increase the sensitivity to allow WS433-CL-04 can add sensors at a longer distance. After that, perform 2 steps of adding sensors and then reset Rssi_threshold = -25.

Enb_auto_add_sensors configuration (see RF MODE CONFIG (in the Modbus Memmap of WS433-CL)): In case you do not want to turn off the power WS433-CL, you can set Enb_auto_add_sensors = 1, this way we have 5 minutes to add nodes (add up to 40 nodes) . After 5 minutes Enb_auto_add_sensors will automatically = 0.

Memmap resgisters

You can download Modbus Memmap of WS433-CL with the following link:

https://filerun.daviteq.com/wl/?id=WBbGm89AToHWyvIyMOc780N1KmjfUr3Y

5.2.2 Add sensor node into WS433-CL-04 (1) through intermediate WS433-CL-04 (2) and Modbus

In case the sensor need to be added to WS433-CL-04 (1) has been installed in a high position, the sensor cannot be brought close to WS433-CL-04 (1). For more details:

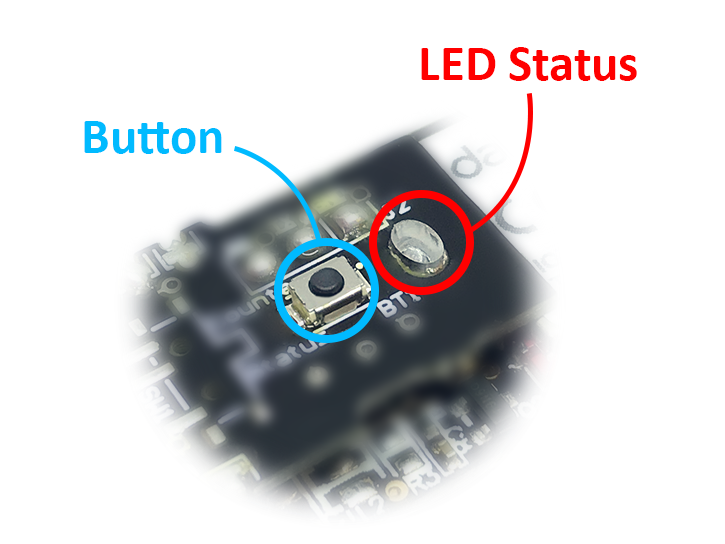

5.3 Button Function

Open the cover of sensor then use the push button to set the data transfer speed for the first 30 seconds when the battery is first installed, after 30 seconds the push button function does not work.

- Press and hold the button for 2 seconds => LED blinks once => Release the button to set Data rate RF 50kbps

- Press and hold the button for 5 seconds => LED blinks twice => Release the button to set Data rate RF 625bps

- Press and hold the button for 10 seconds => LED blinks 3 times => Release the button to reset RF parameters (frequency, RF output power, data rate), if held for more than 30 seconds then the button function does not work.

Reset default WS433:

Frequency: 433.92 MHz

RF transmit power: 15 dBm

RF data rate: 50 kbps

5.4 Configuration

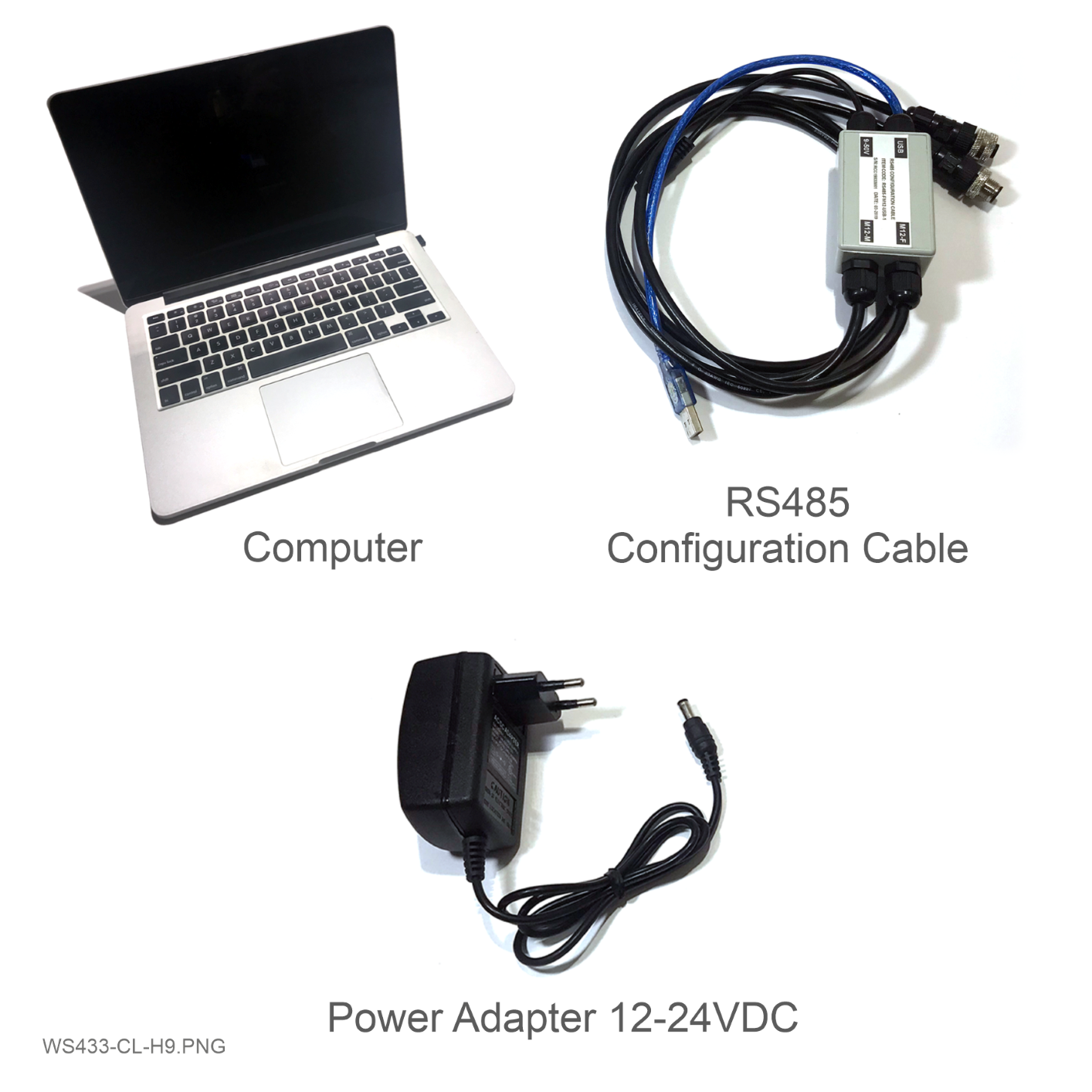

First, you need to prepare

Num of Node will indicate the number of nodes managed by WS433-CL.

Every time a node is added, the Num of Node will increase by 1.

Every time a node is deleted, the Num of Node is reduced by 1.

Writing Num of Node = 0 will delete all 40 node ids to 0.

If you want to delete a node id, then write it = 0 with the Write function is 16 and the Read function is 3.

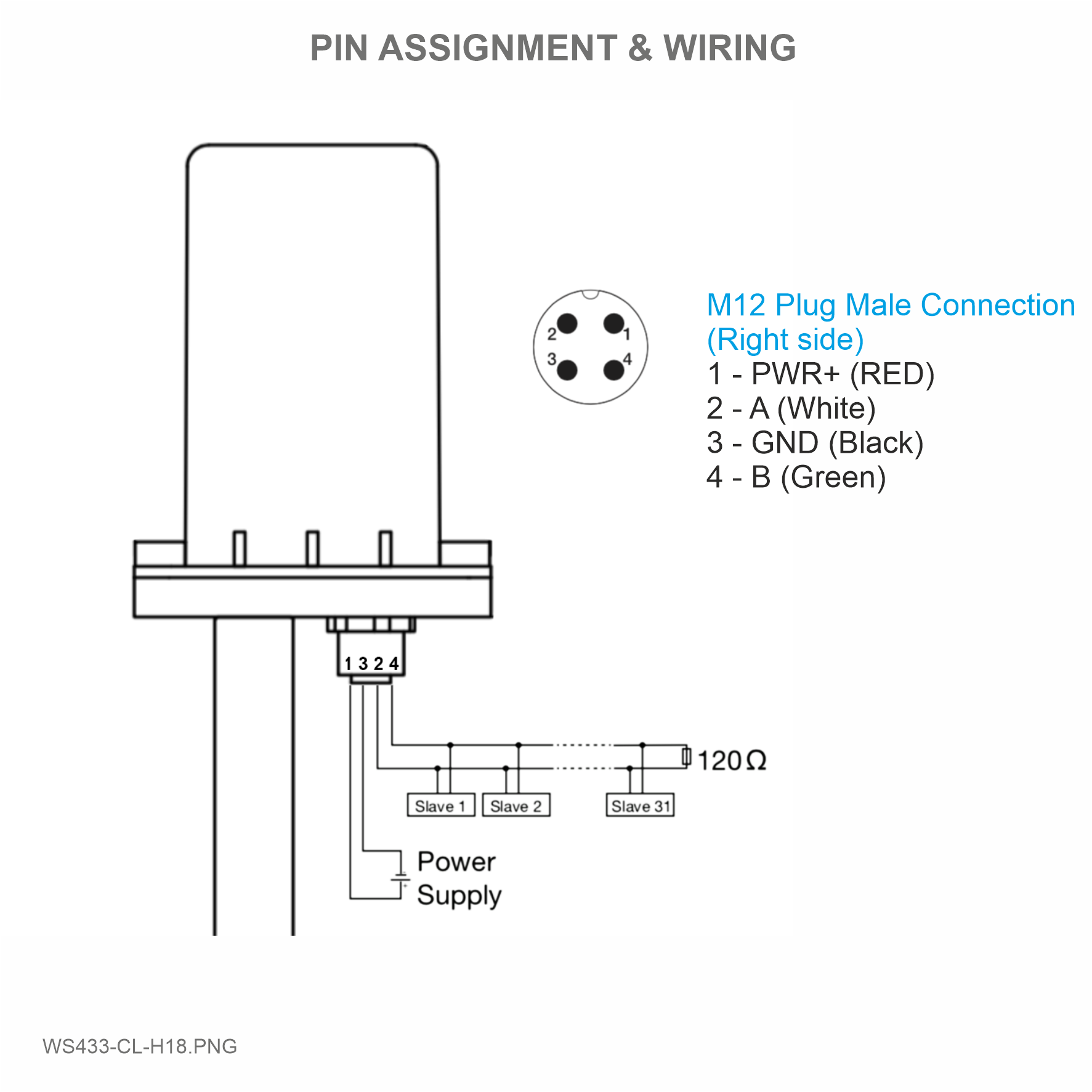

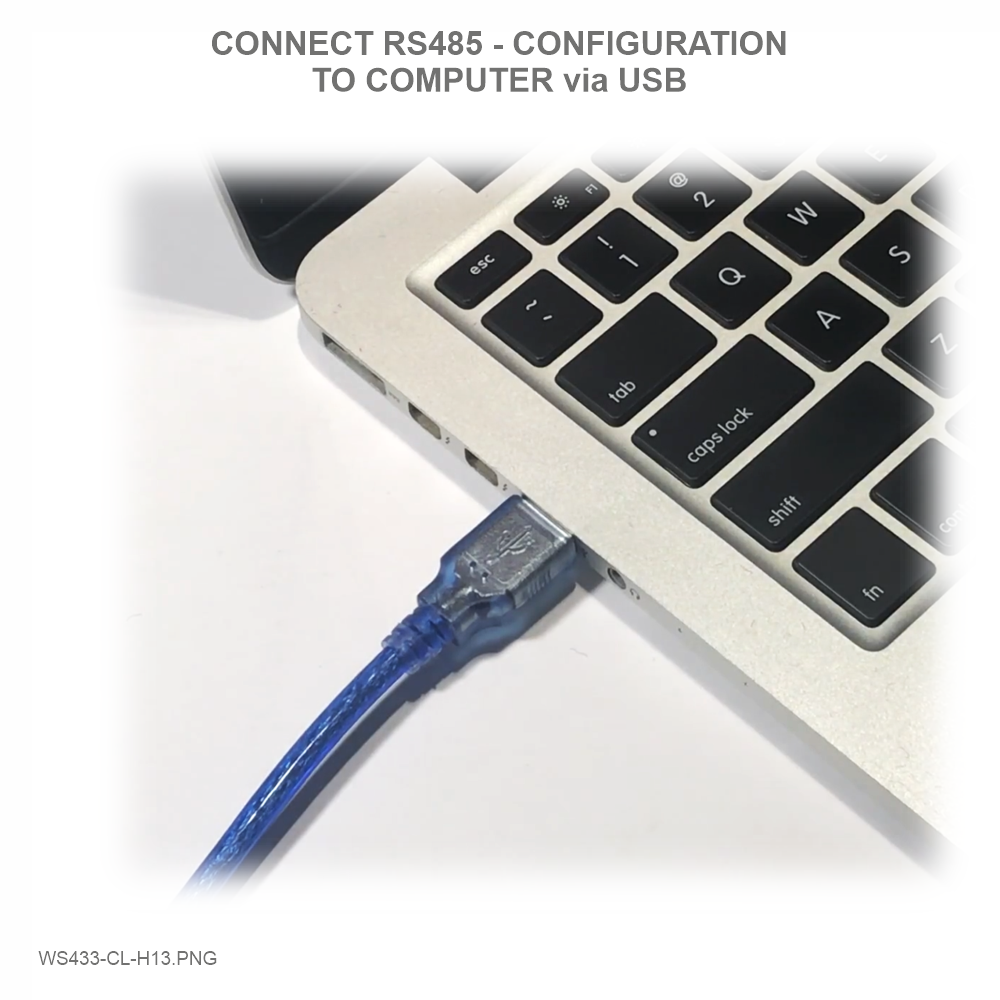

Step 1: Connect Antenna, RS485 - configuration cable and power supply co-ordinator

|

|

|

|

Step 2: Open Modbus tool on PC

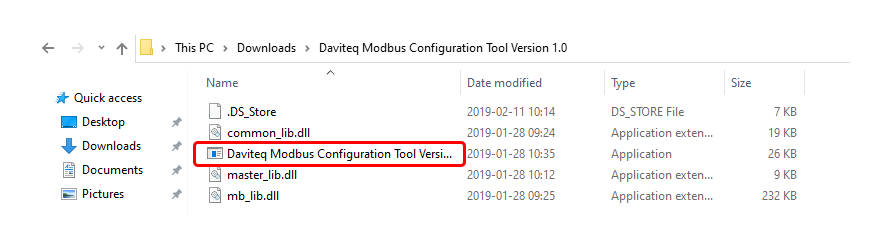

- You can download Daviteq Modbus Configuration Tool with the following link:

https://filerun.daviteq.com/wl/?id=qK0PGNbY1g1fuxTqbFW9SXtEvCw7bpc6

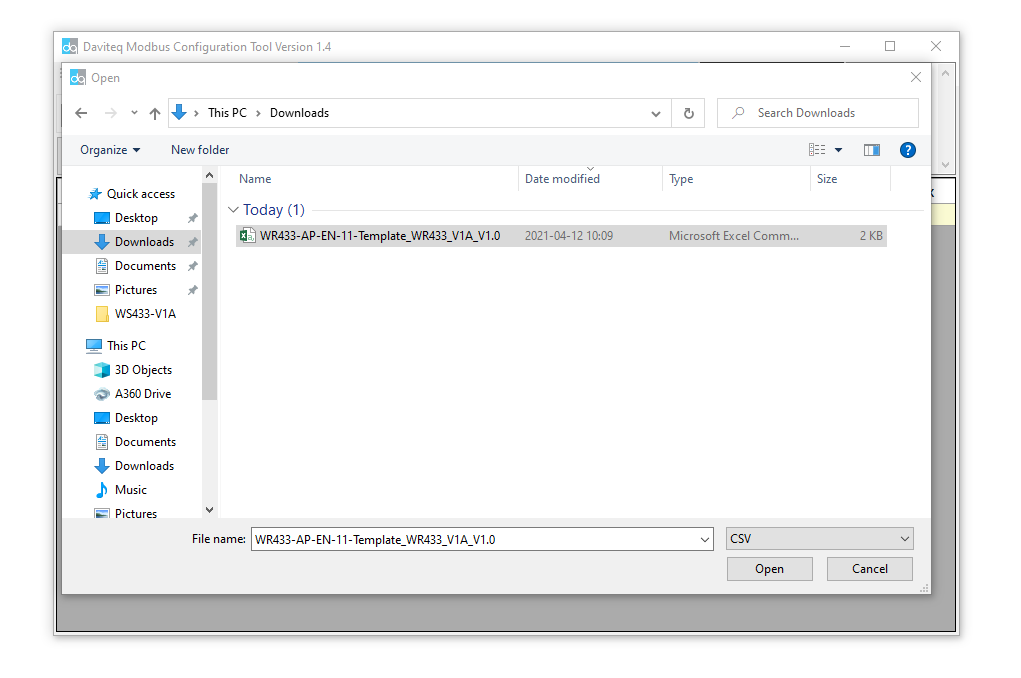

Template File: https://filerun.daviteq.com/wl/?id=ItFaeQgtCmXN98J7GaPdeZvKK5eS1Dd1

How to use the Modbus configuration software

- Unzip file and run file application "Daviteq Modbus Configuration Tool Version"

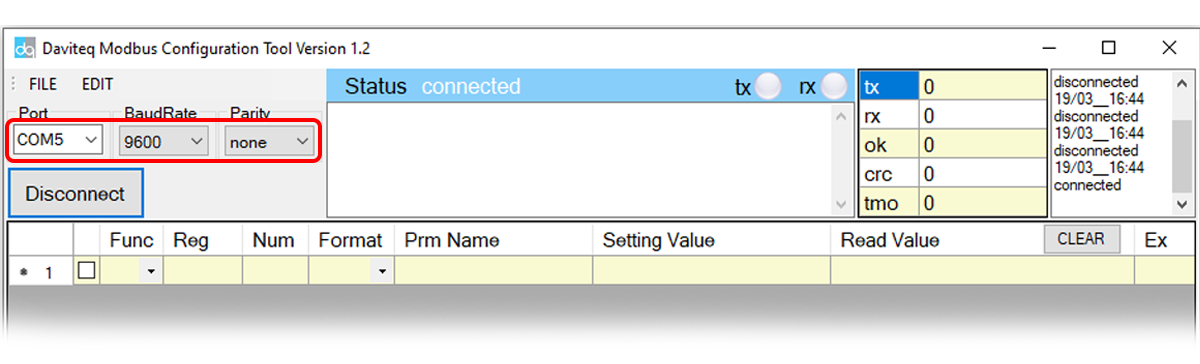

- Choose COM Port (the Port which is USB cable plugged in)

- Set the BaudRate: 9600, Parity: none

- Click “ Connect “ untill the Status displays “disconnected” to “connected“. It means the WS433-CL-04 is being connected with computer;

- Next, we need to import the configuration file for WS433-CL-04 by importing the csv file: Go to MENU: FILE / Import New / => select the template file.

Step 3: Configure parameters of the sensor.

Memmap resgisters

You can download Modbus Memmap of WS433-CL with the following link:

https://filerun.daviteq.com/wl/?id=BKEaUzdArkoc0Hc7nfpRShdPVToVrqQZ

In the memmap file, refer to the Memmap of WS433-V1A sheet to configure the sensor's operating parameters accordingly.

The reference memmap addresses are based on the order of the sensors added in the Memmap file above

Typical sensor parameters:

|

Function Code (Read) |

Function Code (Write) |

# of register |

Byte Size |

Description |

Value Range |

Default |

Format |

Property |

Explanation |

|

4 |

|

1 |

2 |

%Battery of sensor Node |

10,30,60,99 |

|

uint16 |

Read |

Battery level, only 04 levels: 10%, 30%, 60% and 99% (full). When 10% ==> Need to replace the battery |

|

4 |

|

2 |

4 |

Frequency value of sensor Node |

Hz |

|

float |

Read |

Frequency value of sensor Node |

|

4 |

|

2 |

4 |

Peak Acceleration value of sensor Node |

m/s2 |

|

float |

Read |

Peak Acceleration value of sensor Node |

|

4 |

|

2 |

4 |

RMS Acceleration value of sensor Node |

m/s2 |

|

float |

Read |

RMS Acceleration value of sensor Node |

|

4 |

|

2 |

4 |

Peak Velocity value of sensor Node |

mm/s |

|

float |

Read |

Peak Velocity value of sensor Node |

|

4 |

|

2 |

4 |

RMS Velocity value of sensor Node |

mm/s |

|

float |

Read |

RMS Velocity value of sensor Node |

|

4 |

|

2 |

4 |

PeakPeak Displacement value of sensor Node |

µm |

|

float |

Read |

Peak of Peak Distance value of sensor Node |

|

4 |

|

2 |

4 |

RMS Displacement value of sensor Node |

µm |

|

float |

Read |

RMS Distance value of sensor Node |

|

4 |

|

2 |

4 |

Temperature value of sensor Node |

-40 .. +125°C |

|

float |

Read |

Temperature value of sensor Node |

|

3 |

1 |

2 |

Data status of Node |

0-9, 99 |

byte |

Read |

0-9: Interval updated data 99: Disconnected |

||

|

3 |

1 |

2 |

RF Signal strength of Node |

0-4 |

byte |

Read |

From 0 to 4 with 0 is being lost connection RF and 4 is the strongest RF |

||

|

3 |

16 |

1 |

2 |

Cycle_wakeup |

1-3600(s) |

120 |

uint16 |

Read/Write |

Every time interval of Cycle_wakeup, sensor node would ONLY send data to co-ordinator if the new measured value was changed more than the Delta value of the last measured value. Default Cycle_wakeup is 120 seconds |

|

3 |

16 |

1 |

2 |

Cycle_healthsta |

60-7200(s) |

600 |

uint16 |

Read/Write |

Every time interval of Cycle_healthsta, sensor node will absolutely send data to co-ordinator regardless any condition (Recommended : 900 seconds) |

|

3 |

16 |

2 |

4 |

Radio frequency |

433.05-434.79, 433 Mhz |

433.92 |

float |

Read/Write |

Configure the operating frequency of wireless sensor by Co-ordinator, should be configured from 433.05-434.79 MHz, only for advanced users |

6. Installation

6.1 Installation location

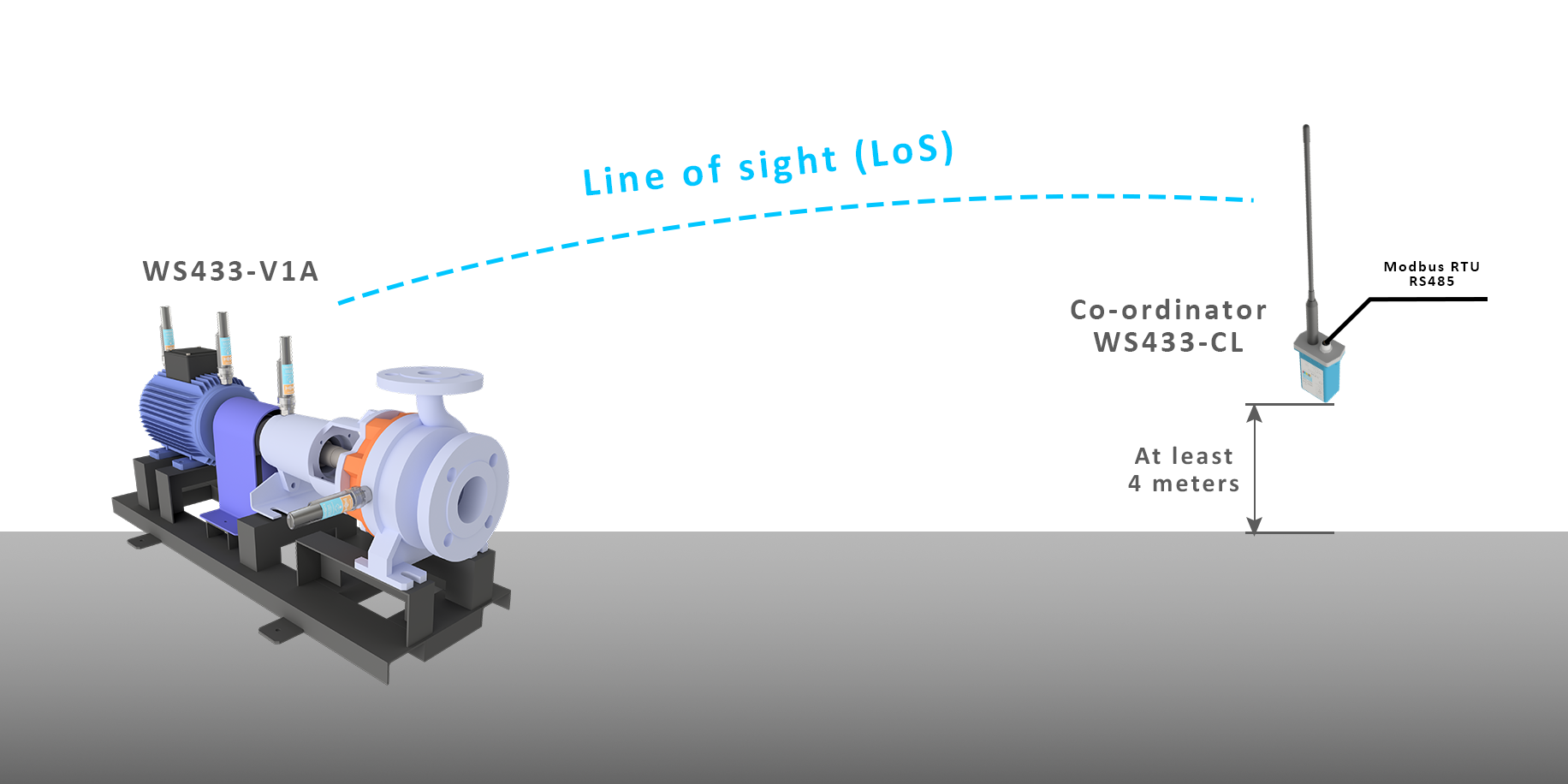

Wireless sensor utilize the ultra-low power 433Mhz RF signal to transmit/receive data with Wireless co-ordinator.

To maximize the distance of transmission, the ideal condition is Line-of-sight (LOS) between the Wireless sensor and Gateway. In real life, there may be no LOS condition. However, the two modules still communicate each other, but the distance will be reduced significantly.

ATTENTION:

DO NOT cover the Wireless sensor or its antenna inside a completed metallic box or housing, because the RF signal can not pass through the metallic material.

NOTE:

Integrated WS433-CL / iConnector Coordinator The coordinator must be placed at least 4 meters above the ground and the WS433-V1A clearly visible.

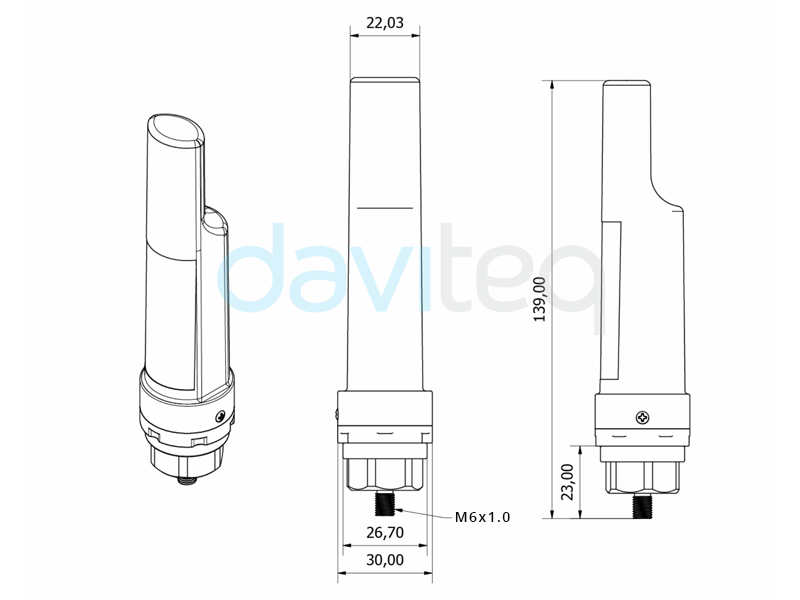

6.2 Dimensions

Unit: mm

6.3 Process mounting

- WARNINGS:

- The sensor should be mounted on an oil-free and grease-free surface as close to the source of vibration as possible.

- For best results, the sensor should be mounted via a drill hole and have an M6x1.0 threaded hole (an adapter can be used) attached directly to the housing.

- Please make sure that the operating ambient temperature is right for the sensor.

- Prepare the professional tools for installation. The inappropriate tools may cause damage to the sensor.

|

|

6.4 Battery installation

Steps for battery installation:

Step 1: Using Philips screw driver to unscrew M2 screw at the side of housing.

Step 2: Pull out the cover then insert the AA 1.5VDC battery, please take note the poles of the battery.

ATTENTION:

Because of O-ring, it requires to have much pulling force at the beginning, therefore please do it carefully to avoid the damage of circuit board which is very thin (1.00mm);

REVERSED POLARITY OF BATTERIES IN 10 SECONDS CAN DAMAGE THE SENSOR CIRCUIT !

Step 3: Insert the top plastic housing and locking by M2 screw

7. Troubleshooting

| No. | Phenomena | Reason | Solutions |

| 1 | The status LED of wireless sensor doesn't light up |

|

|

| 2 | Wireless sensor not connected to co-ordinator |

|

|

8. Support contacts

|

Manufacturer Daviteq Technologies Inc Email: info@daviteq.com | www.daviteq.com |

Distributor in Australia and New Zealand Templogger Pty Ltd Tel: 1800 LOGGER Email: contact@templogger.net |

No Comments