USER GUIDE FOR LONG RANGE WIRELESS CO-ORDINATOR WS433-CL

| WS433-CL-MN-EN-01 |

FEB-2020 |

This document is applied for the following products

| SKU | WS433-CL | HW Ver. | 2.4 | FW Ver. | 1.9 |

| Item Code |

WS433-CL-04 | Wireless Sensor Co-ordinator with external antenna 0 dbi, M12-Female connector, 4-pin, coding A, RS485 ModbusRTU | |||

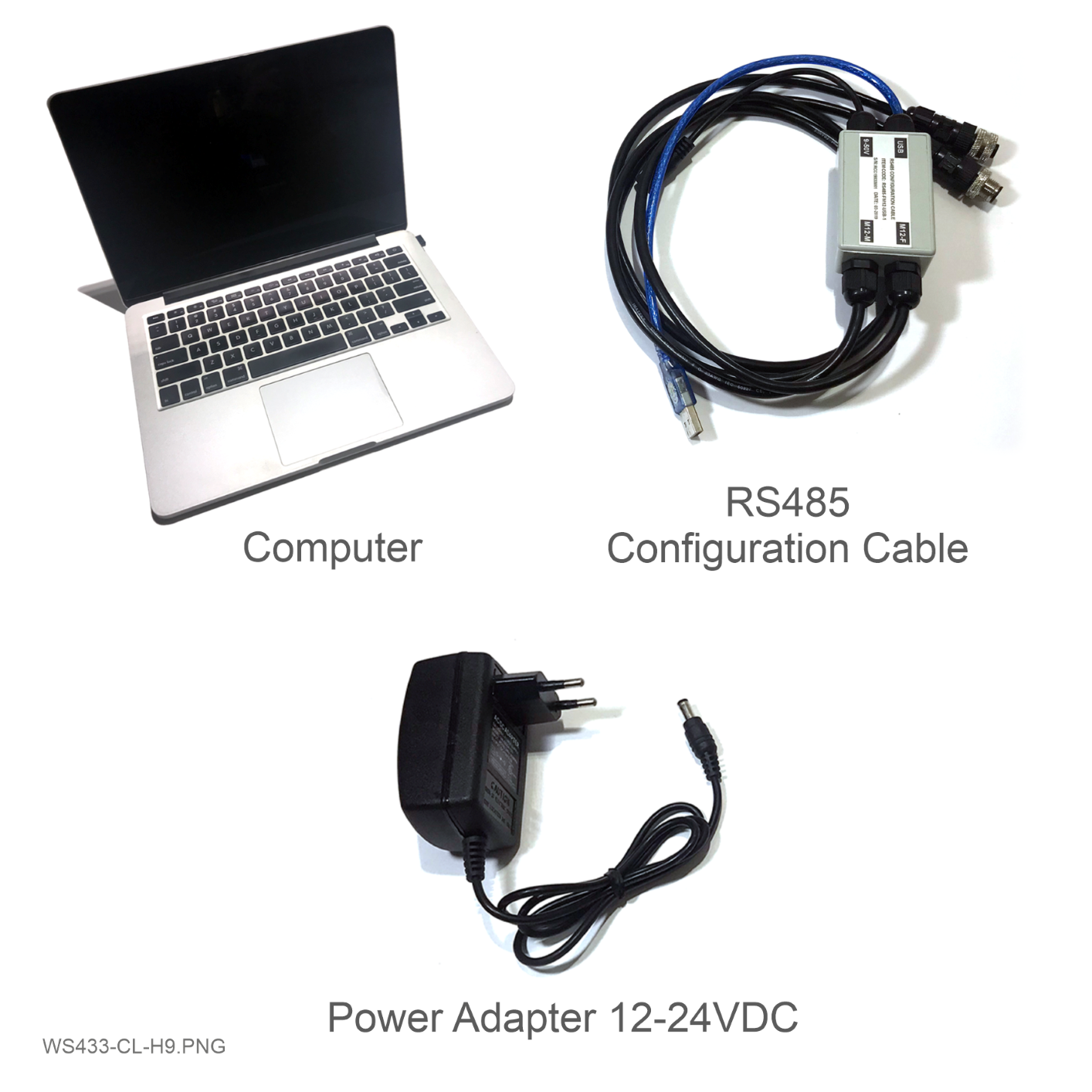

| RS485-FM12-USB-1 | RS485/USB multi-purpose Configuration cable** with connector m12 male, female and flying leads, with Power adapter 12VDC/2.0A | ||||

1. Functions Change Log

| HW Ver. | FW Ver. | Release Date | Functions Change |

| 2.4 |

1.9

|

NOV-2019 |

|

2. Introduction

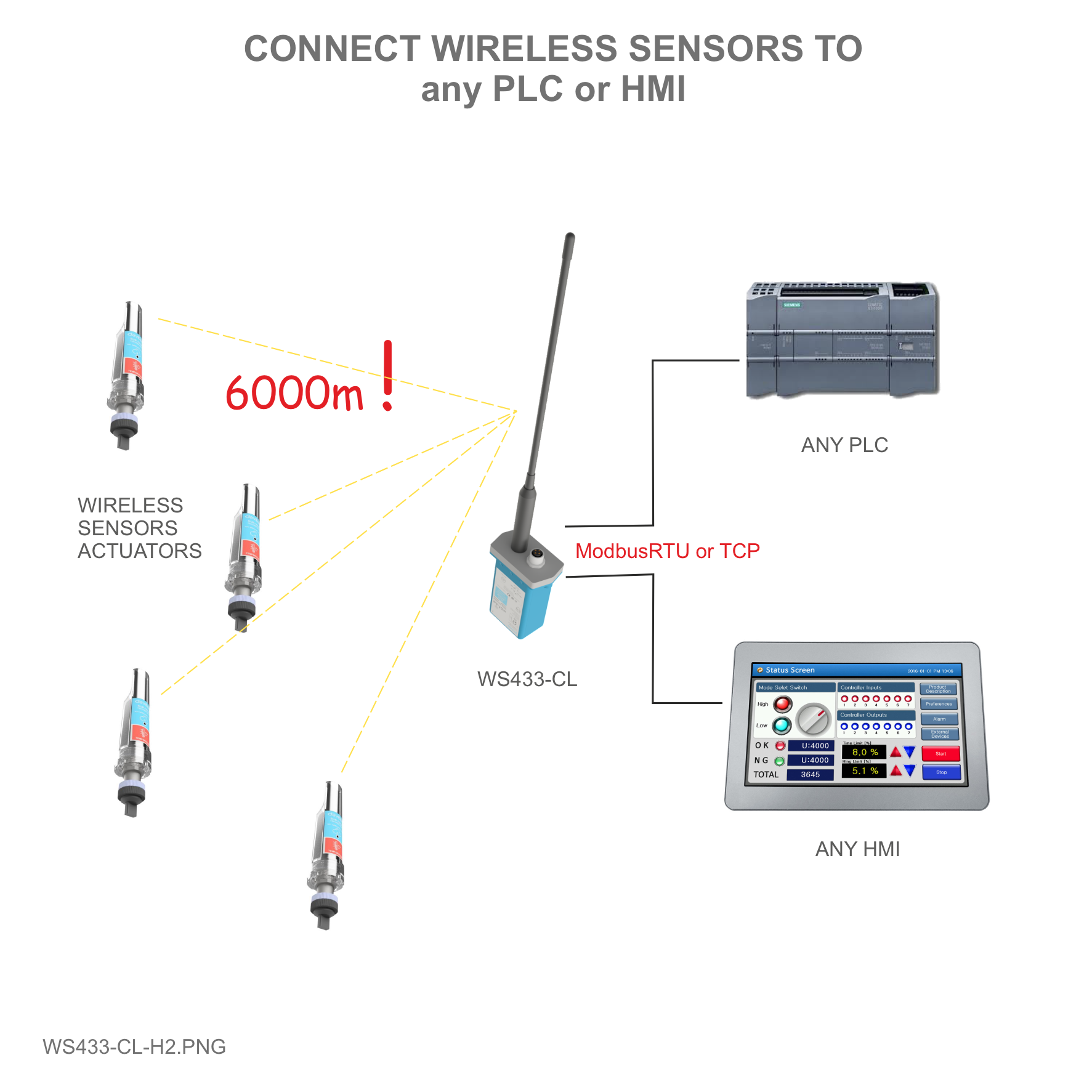

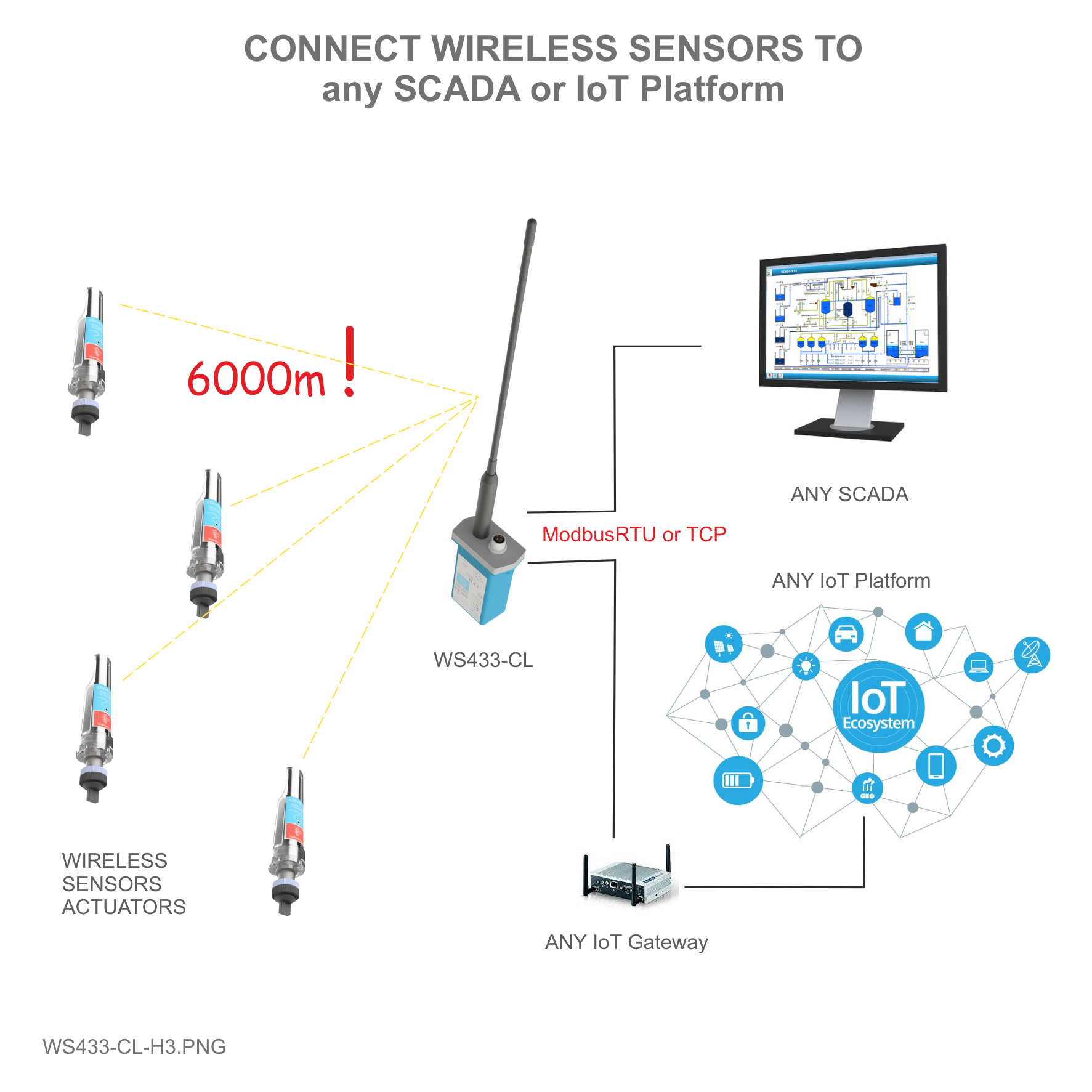

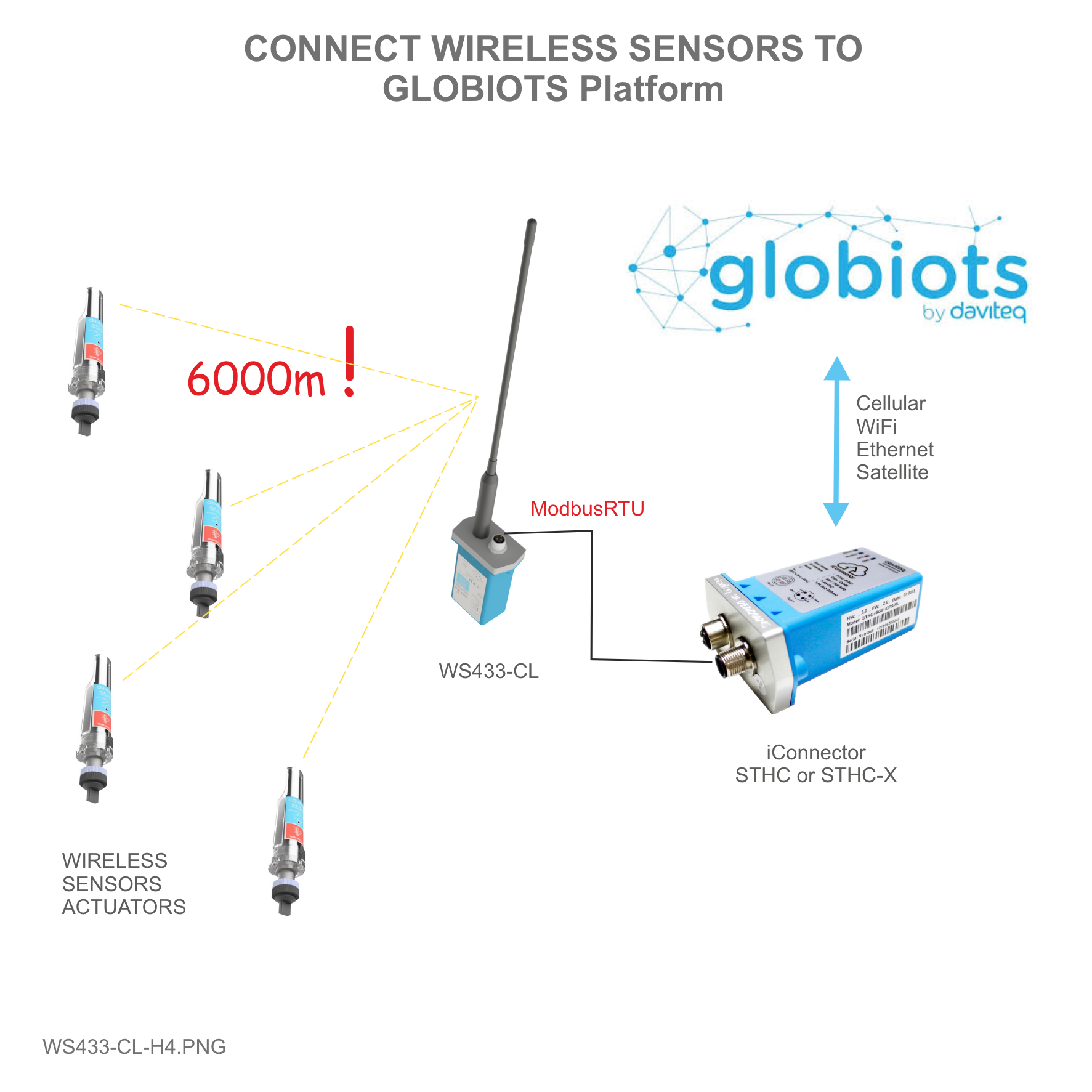

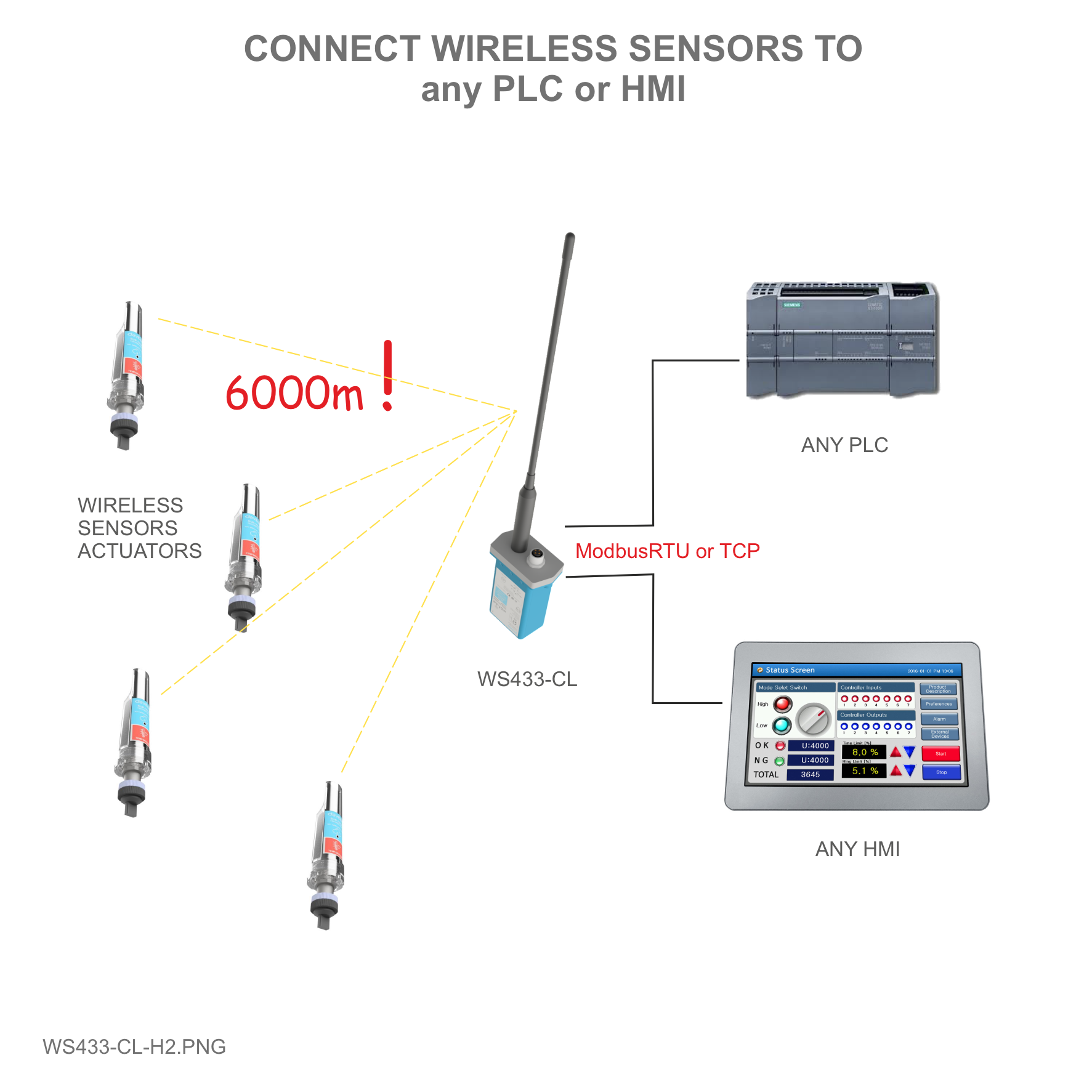

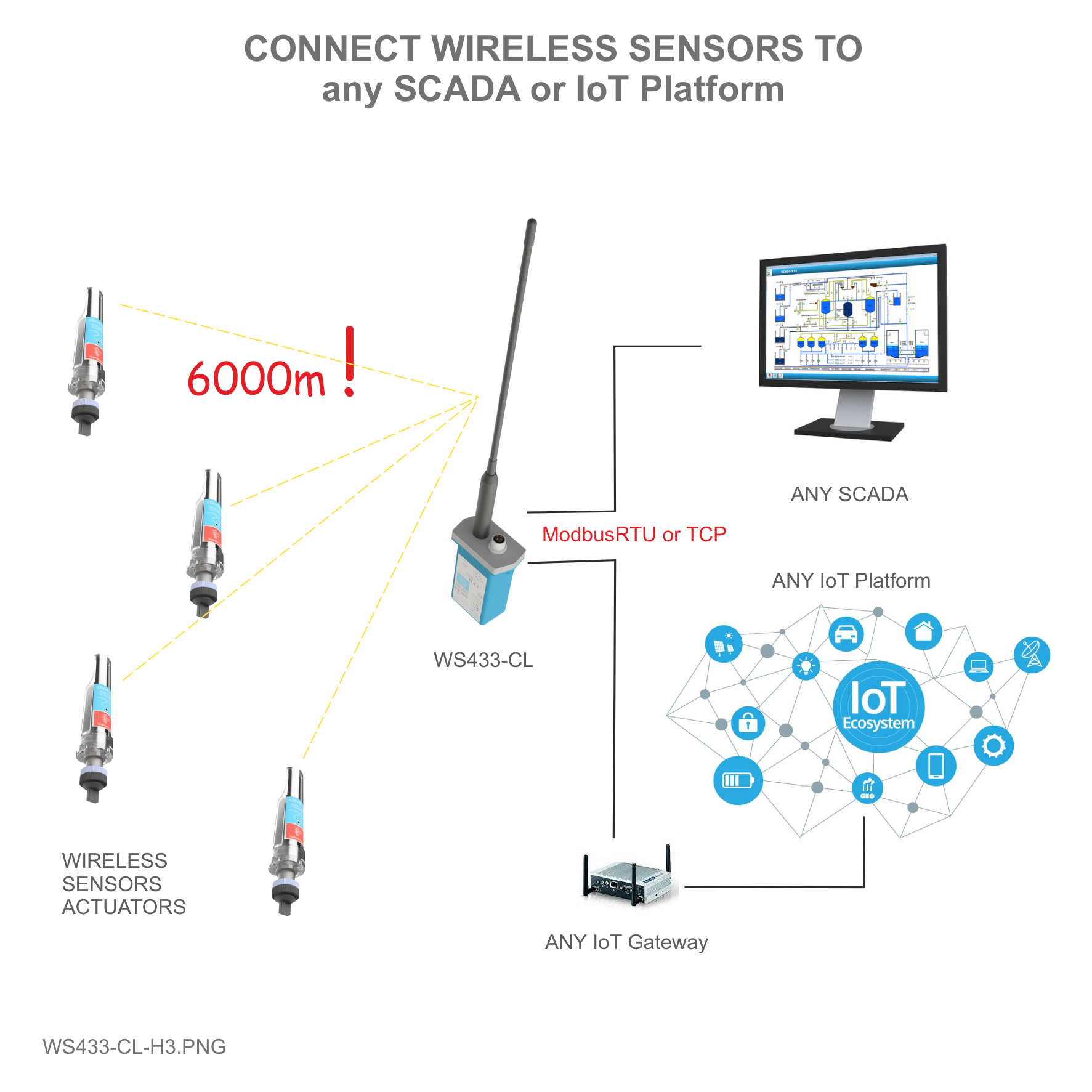

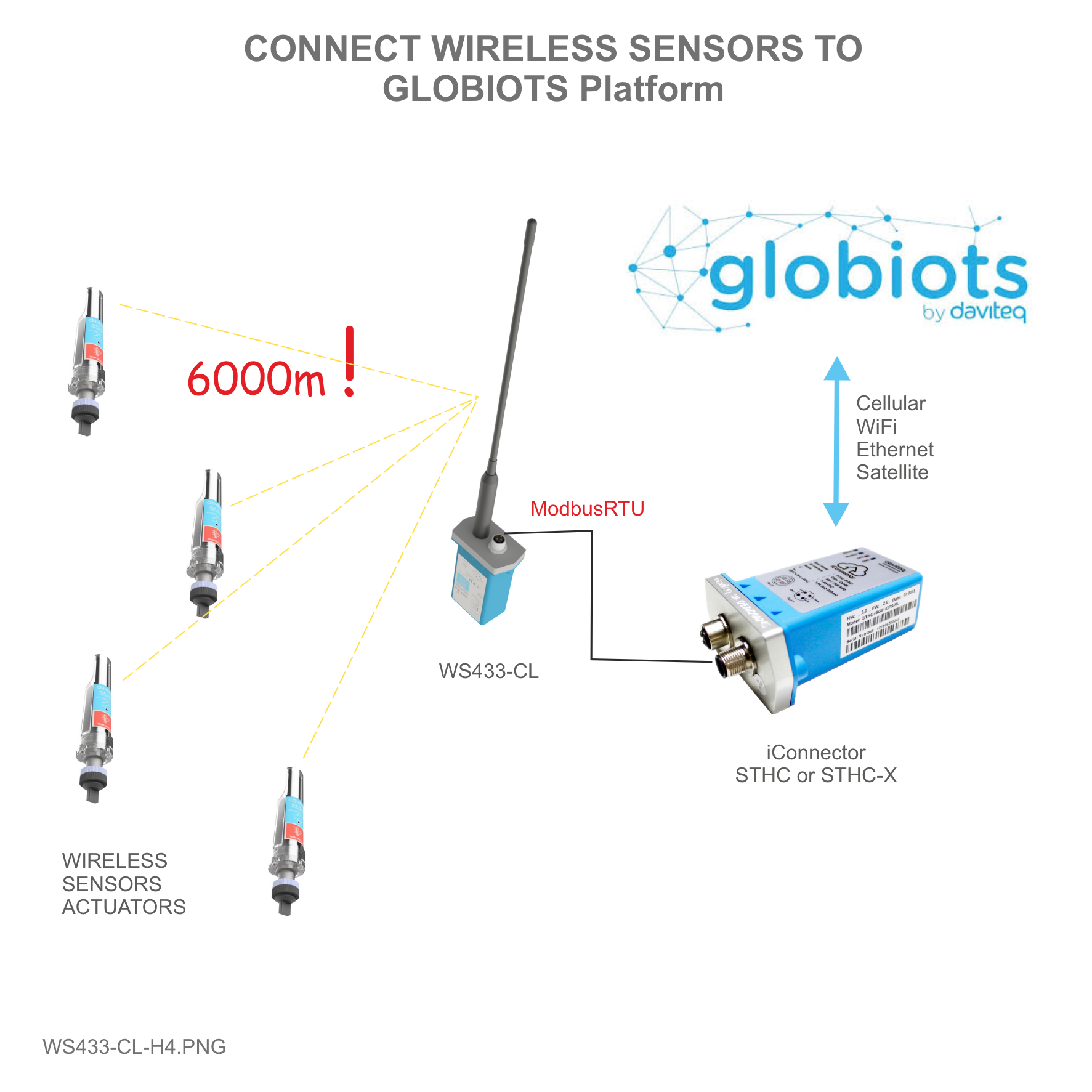

WS433-CL is a wireless co-ordinator in a wireless sensor network, a high-performance type. It is able to configure the parameters for all end nodes in the network. By the Sub-Ghz technology from Texas Instruments, it is easy to establish multiple networks in same area without interference or channel conflict. One co-ordinator can handle maximum of 40 end nodes in its network. LOS transmission distance up to 6000m. The WS433-CL also has the option of adding an IoT Gateway built-in to facilitate remote configuration and diagnostics, as well as remote monitoring and control via any IIoT platform. The installation and configuration is very simple. Setting up a wireless sensor network has never been this easy.

3. Specification

| Communication | RS485 |

| Data speed | Up to 50kbps |

| Tranmission distance | LOS 6000m @ 50 kpbs (antenna height is 4m minimum) |

| Antenna | Standard external antenna 0 dbi, option 3dbi, 6dbi, 9dbi |

| Power supply | 7..48 Vdc @ 500mA max |

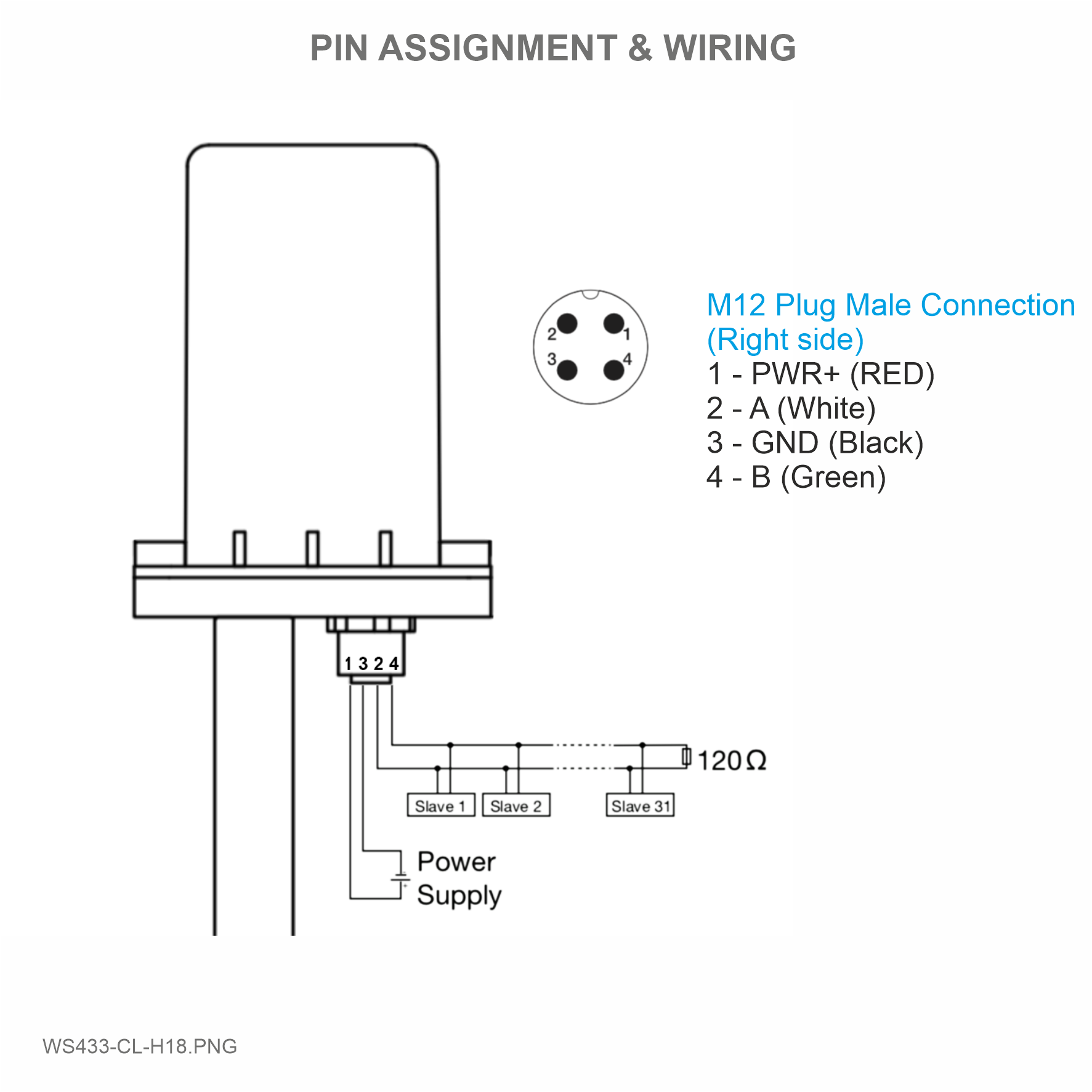

| Electrical connector | M12-female, 4-pin A-coding |

| RF frequency band | Free license ISM 433.92Mhz (for others 868, 915, 920Mhz, refer related datasheets) |

| Ready to comply | ETSI EN 300 220, EN 303 204 (Europe) FCC CFR47 Part15 (US), ARIB STD-T108 (Japan)** |

| Vietnam Type Approval Certification | QCVN 73:2013/BTTTT, QCVN 96:2015/BTTTT (DAVITEQ B00122019) |

| Security Standard | AES-128 |

| Operating temperature | -40oC..+85oC |

| Housing | Aluminum + Polycarbonate, IP67 |

| Included accessories | Mounting bracket for wall mount |

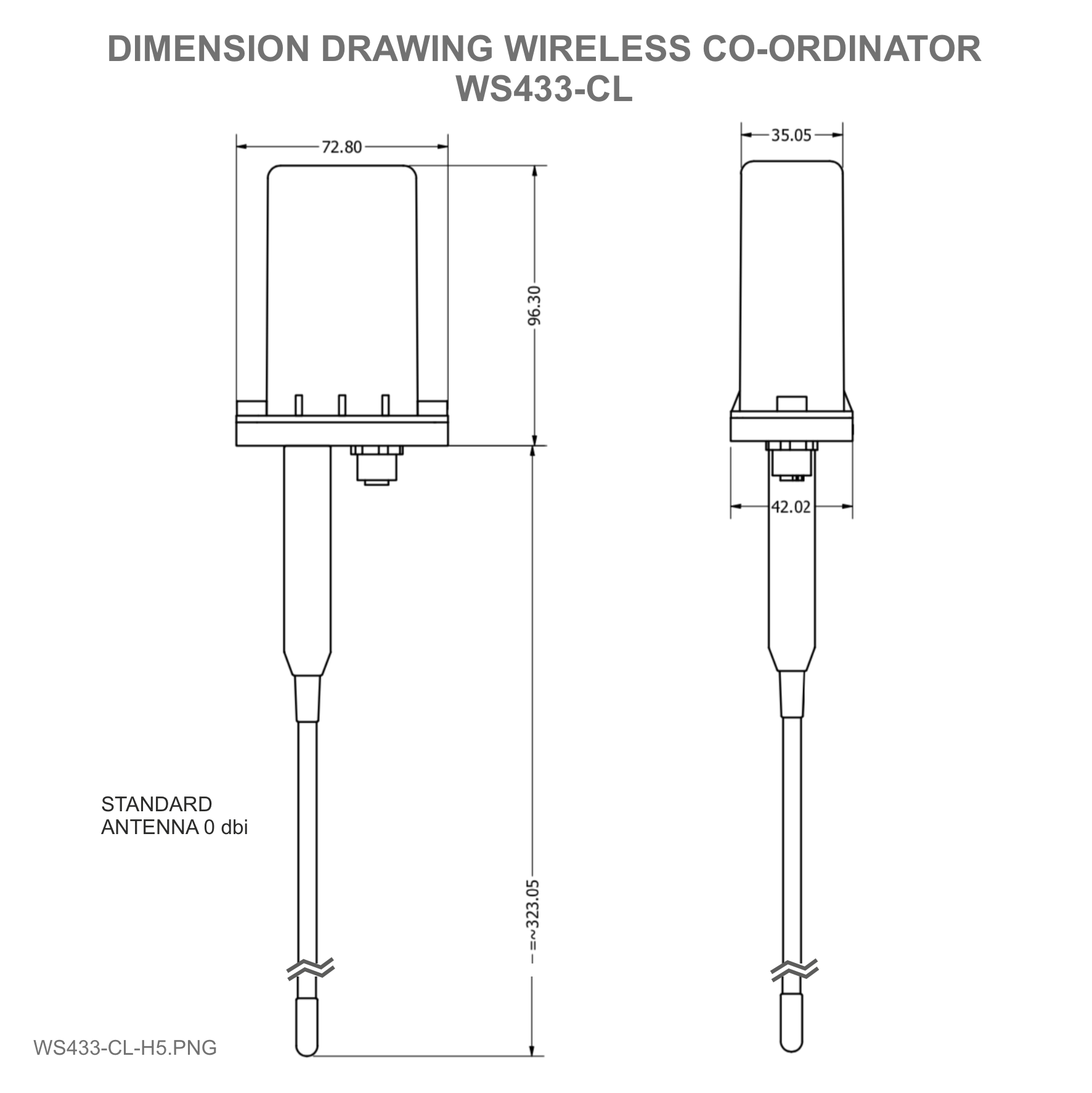

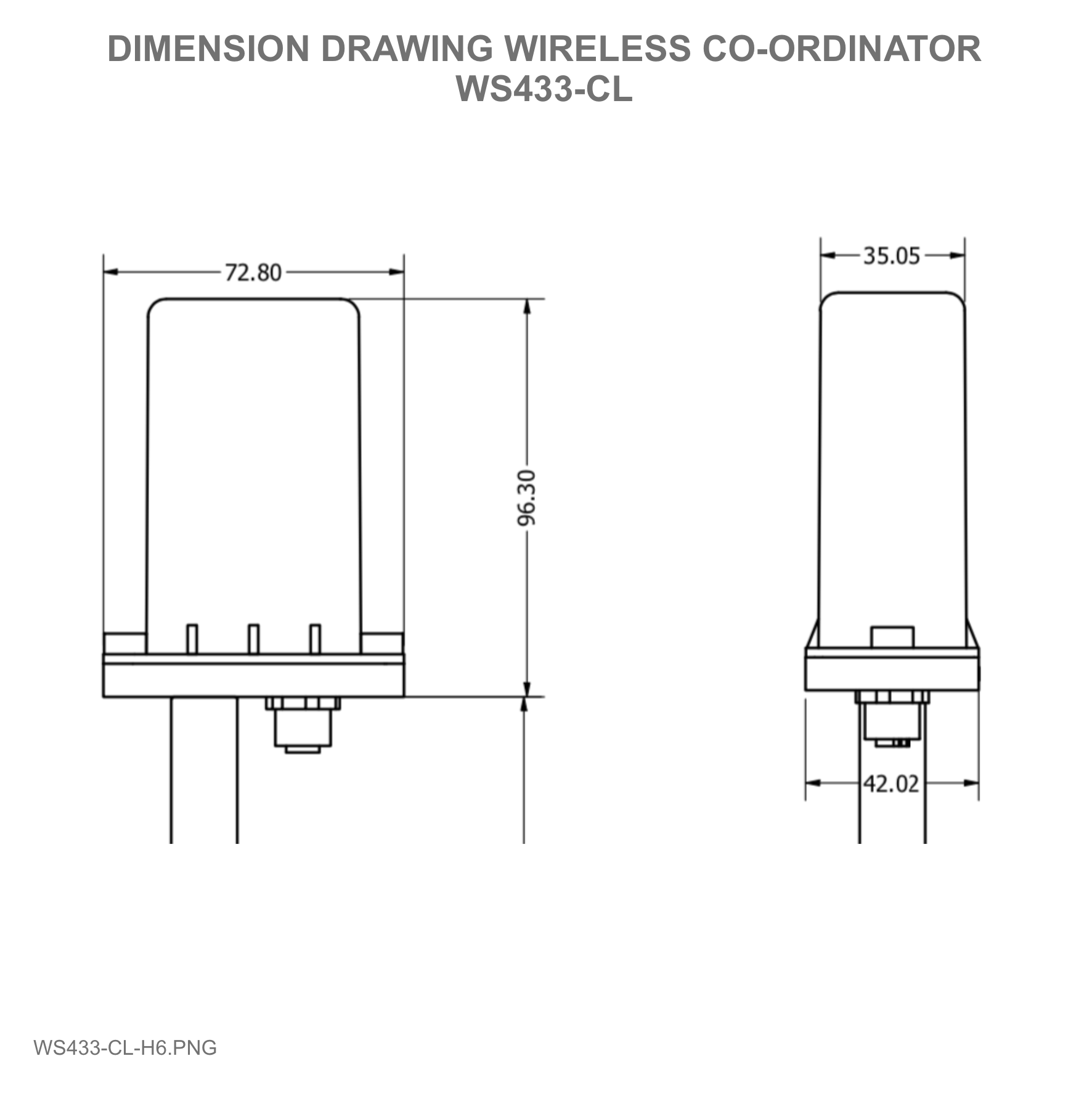

| Product dimension | H106 x W73x D42 mm (excluded antenna) |

| Net weight | 190 grams |

| Box dimension | W160 x D150 x H100 mm |

| Gross weight | < 300g |

4. Product Pictures

|

|

|

|

|

|

|

|

5. Operation Principle

5.1 Add sensors node to Co-ordinator WS433-CL

5.1.1. Add Sensor Node ID automatically

|

|

Step 1: After supplying power the Co-ordinator via M12 connector, the Node ID must be registered within the first 5 minutes, up to 40 WS.

Step 2: Bring the wireless sensor closer to the Co-ordinator's antenna then take off the wireless sensor battery, wait for 5s then insert the battery again. If:

- Buzzer plays 1 peep sound, LED blink 1 time, that means registering Node ID on Co-ordinator successfully.

- Buzzer plays 2 peep sounds, LED blink 2 times, that this Node ID is already registered.

If you do not hear the "Peep" sound, please disconnect the power the co-ordinator, wait a few minute and try again.

Node id added in this way will be written to the smallest node_id_n address which is = 0.

Set Rssi_threshold (see RF MODE CONFIG (in the Modbus Memmap of WS433-CL), default -25): The case if Co-ordinator is on high position and need to add node sensor. We set the sensor as close as possible and set the Rssi_threshold to -80, -90 or -100 to increase the sensitivity to allow WS433-CL-04 can add sensors at a longer distance. After that, perform 2 steps of adding sensors and then reset Rssi_threshold = -25.

Enb_auto_add_sensors configuration (see RF MODE CONFIG (in the Modbus Memmap of WS433-CL)): In case you do not want to turn off the power WS433-CL, you can set Enb_auto_add_sensors = 1, this way we have 5 minutes to add nodes (add up to 40 nodes) . After 5 minutes Enb_auto_add_sensors will automatically = 0.

Memmap resgisters

You can download Modbus Memmap of WS433-CL with the following link:

https://filerun.daviteq.com/wl/?id=BKEaUzdArkoc0Hc7nfpRShdPVToVrqQZ

5.1.2 Add sensor node into WS433-CL-04 (1) through intermediate WS433-CL-04 (2) and Modbus

IN CASE the sensor need to be added to WS433-CL-04 (1) has been installed in a high position, the sensor cannot be brought close to WS433-CL-04 (1).

First, you need to prepare

For example: WS433-CL-04 (1) has connected 1 sensor node and needs to connect 1 more sensor node WS433-M12F. So we use a WS433-CL-04 (2) to configure the 2nd sensor connected to WS433-CL-04 (1)

Step 1: Add Sensor Node ID automatically to WS433-CL-04 (2) (steps as above video)

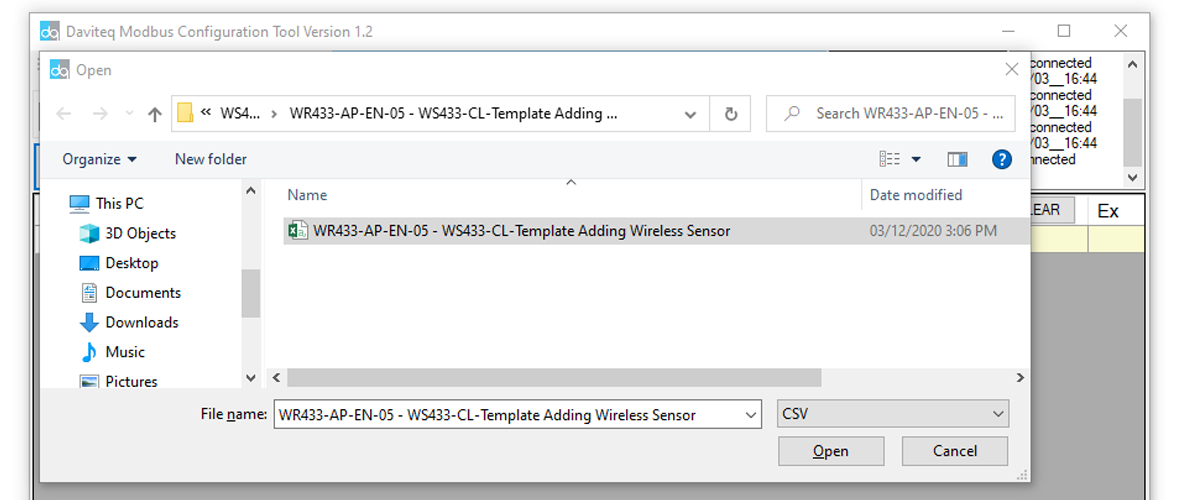

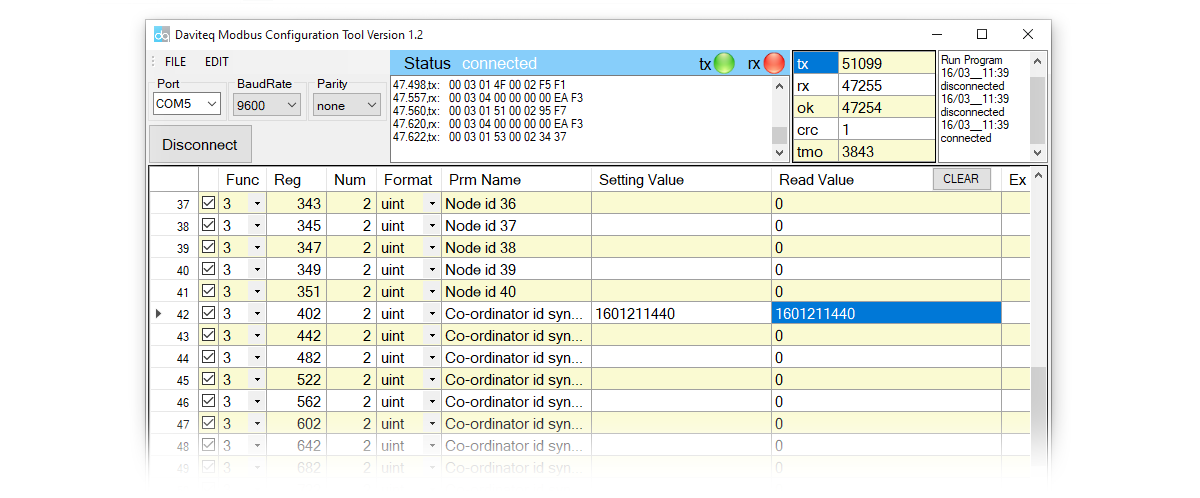

Step 2: Use the RS485 configuration cable to communicate with the Co-ordinator WS433-CL-04 (2) via Modbus software (in the link below), then write the ID of the Co-ordinator WS433-CL-04 (1) into "Co-ordinator id" and sync with the sensor node

Daviteq Modbus Configuration Tool: https://filerun.daviteq.com/wl/?id=yDOjE5d6kqFlGNVVlMdFg19Aad6aw0Hs

Template WS433-CL-Template Adding Wireless Sensor: https://filerun.daviteq.com/wl/?id=cuVB3swlFLoYbiZeK11hpO0w8NW2vU7w

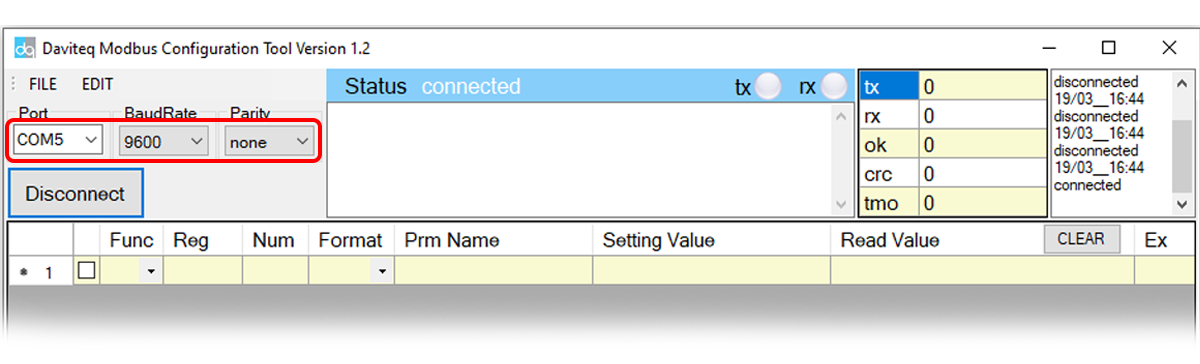

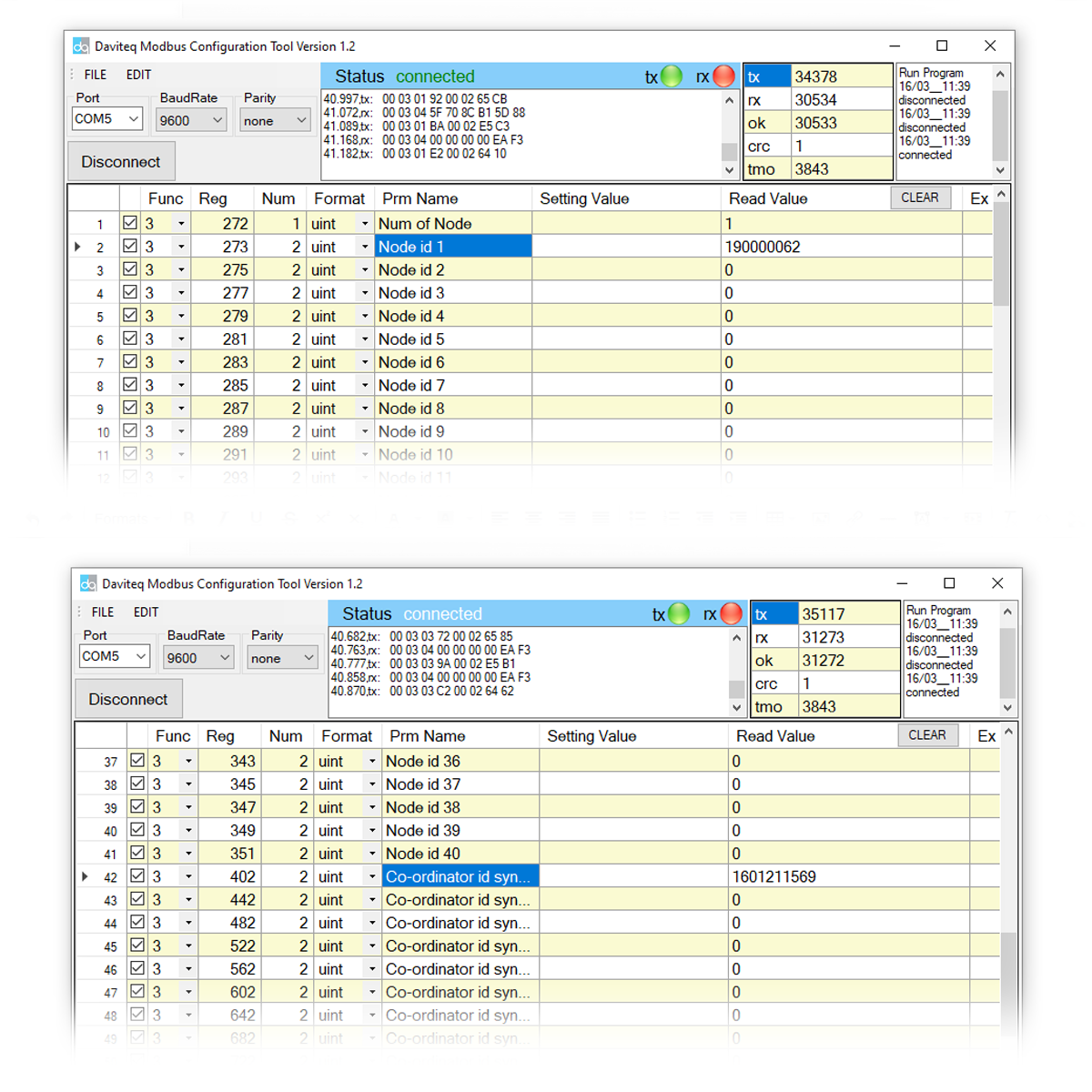

How to use the Modbus configuration software

|

|

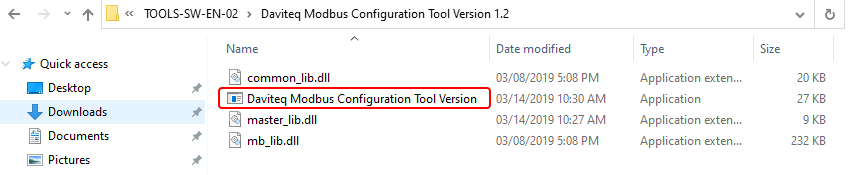

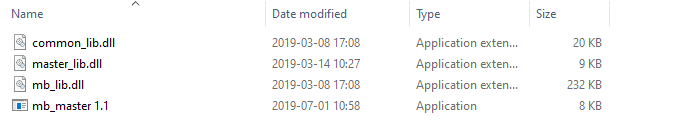

- Unzip file and run file application Daviteq Modbus Configuration Tool Version

- Choose COM Port (the Port which is USB cable plugged in)

- Set the BaudRate: 9600, Parity: none

- Click “ Connect “ untill the Status displays “disconnected” to “connected“. It means the WS433-CL-04 is being connected with computer;

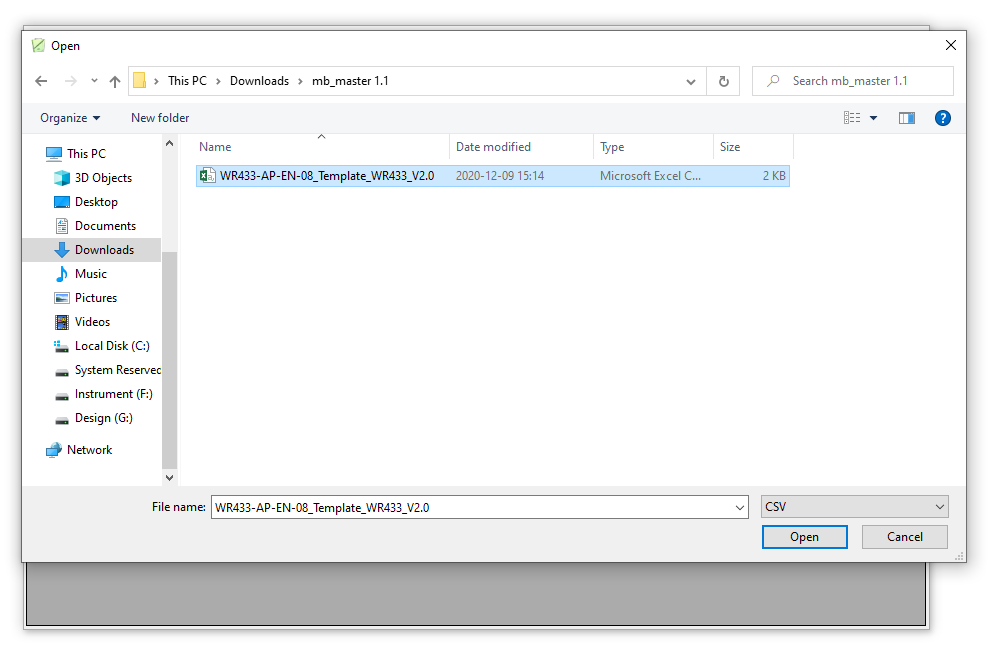

- Next, we need to import the configuration file for WS433-CL-04 by importing the csv file: Go to MENU: FILE / Import New / => select the file with name WS433-CL-Template Adding Wireless Sensor.csv (after unzip file).

- We can see that WS433-CL-04 (2) has connected the sensor to the sensor's id node s/n and the co-ordinator id s/n syncs with the sensor

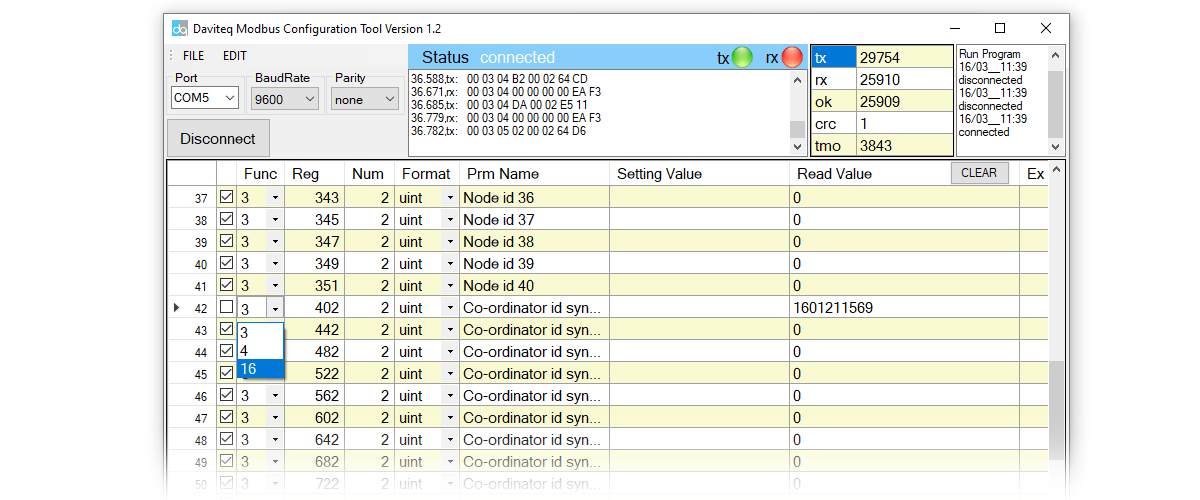

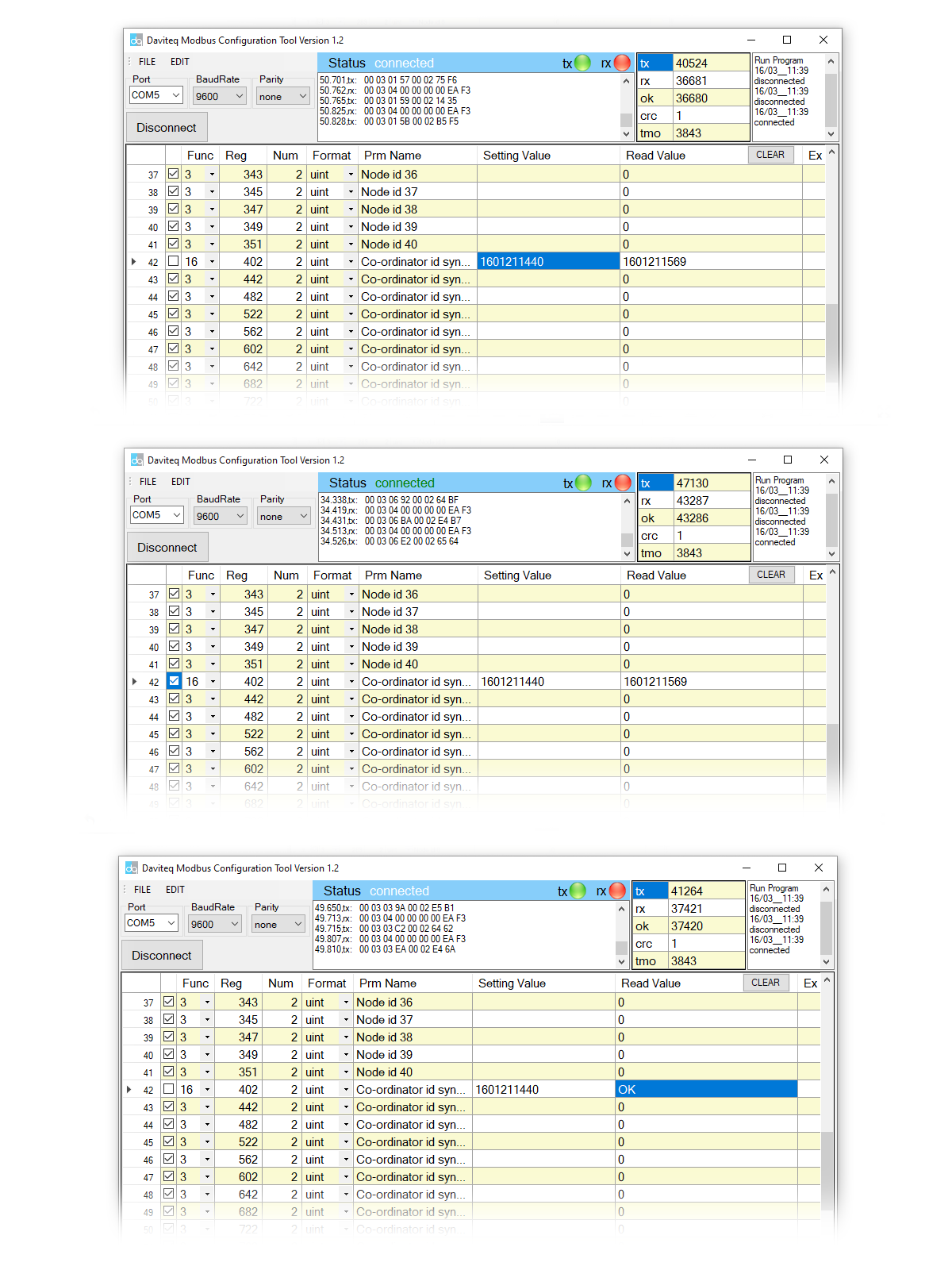

- In the row Co-ordinator id sync to node 1, we change the co-ordinator id WS433-CL-04 (2) of sensor node to co-ordinator id WS433-CL-04 (1) by Uncheck Func 3 => change Func from 3 to 16

- Type in Setting Value the co-ordinator id of WS433-CL-04 (1) => Check Func 16 if Read Value show OK which mean it's wrote successful

- Change Func 16 to 3 then Check to read the value we just wrote in => if Read Value show the co-ordinator id of WS433-CL-04 (1) that mean the sensor node has sync with WS433-CL-04 (1)

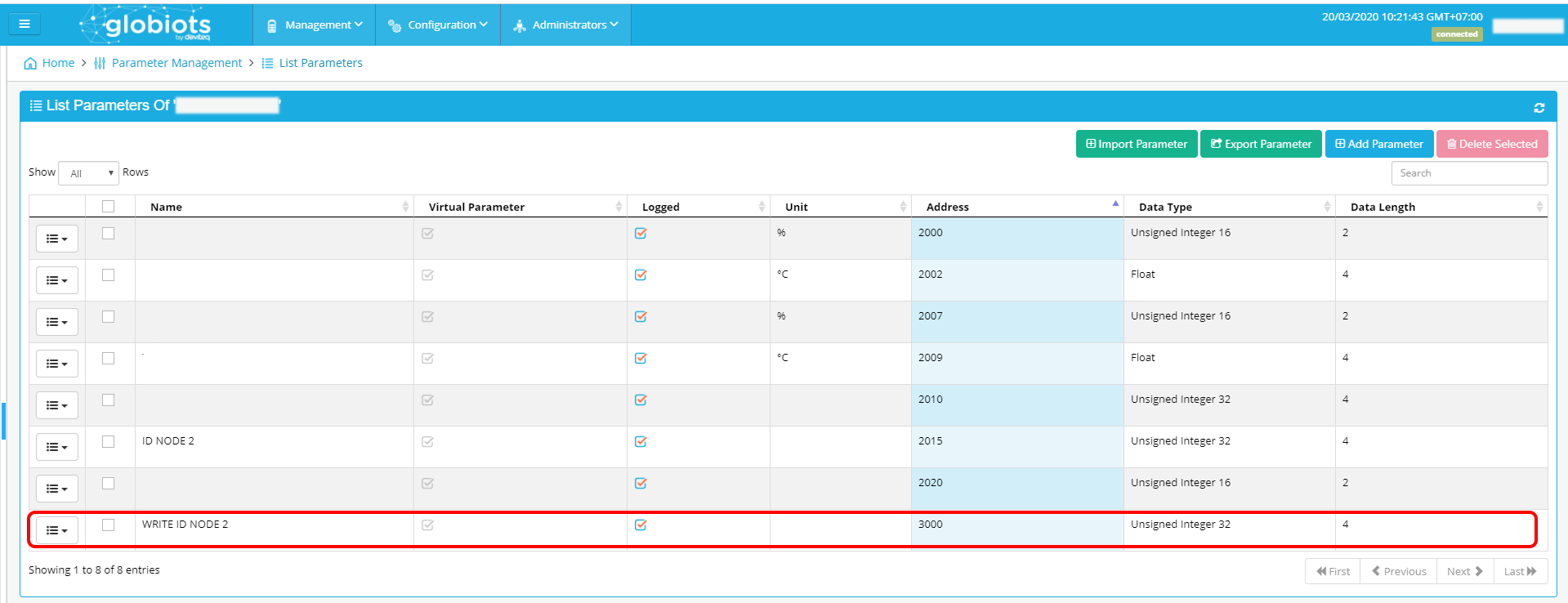

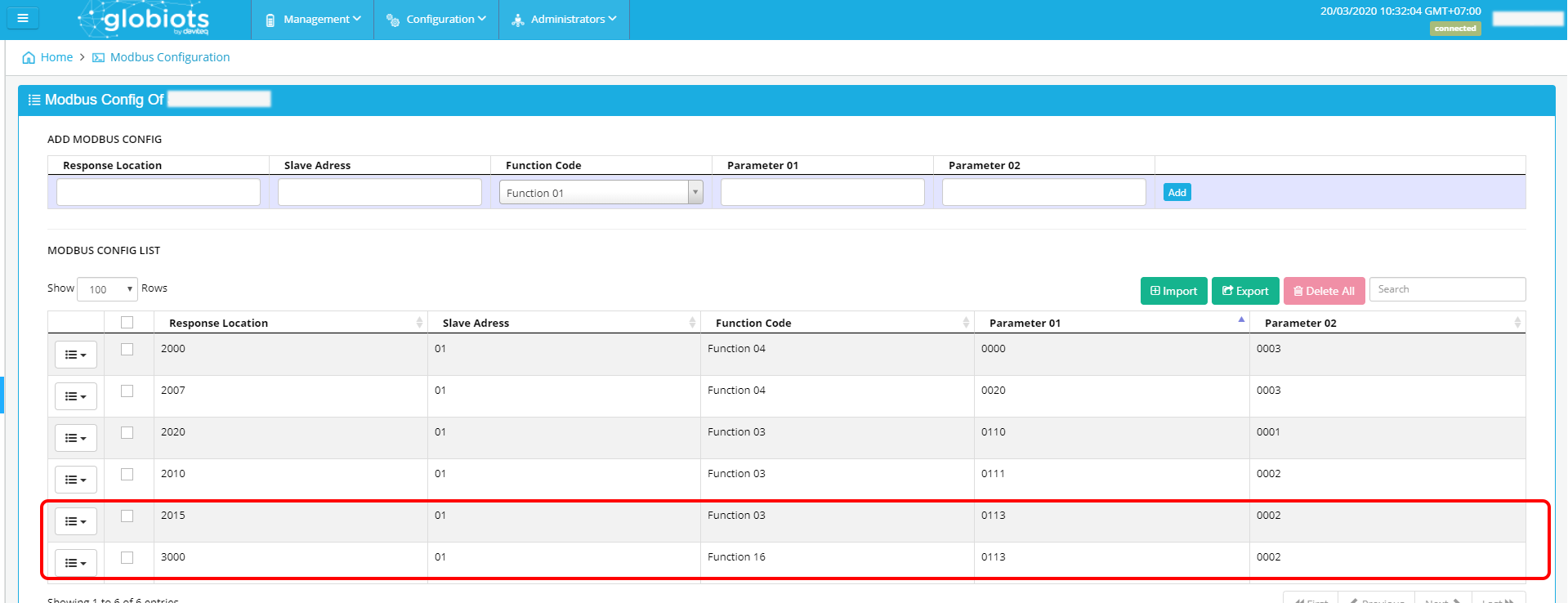

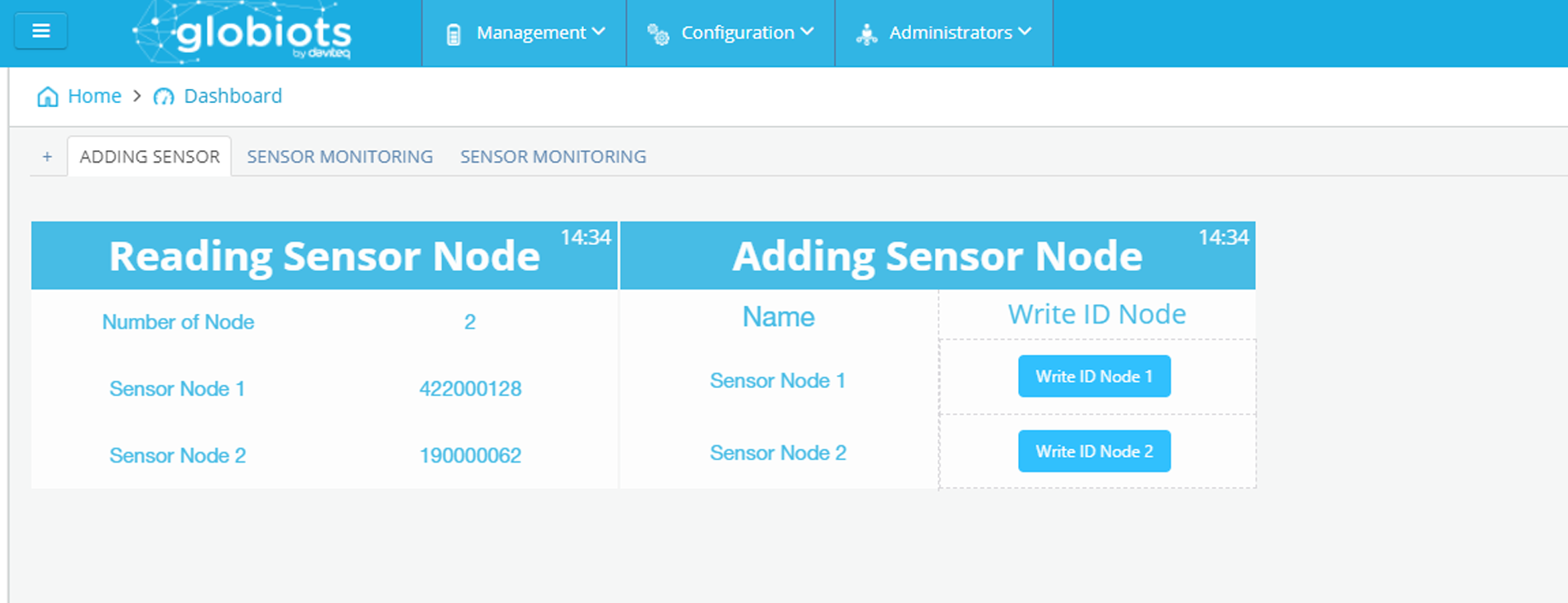

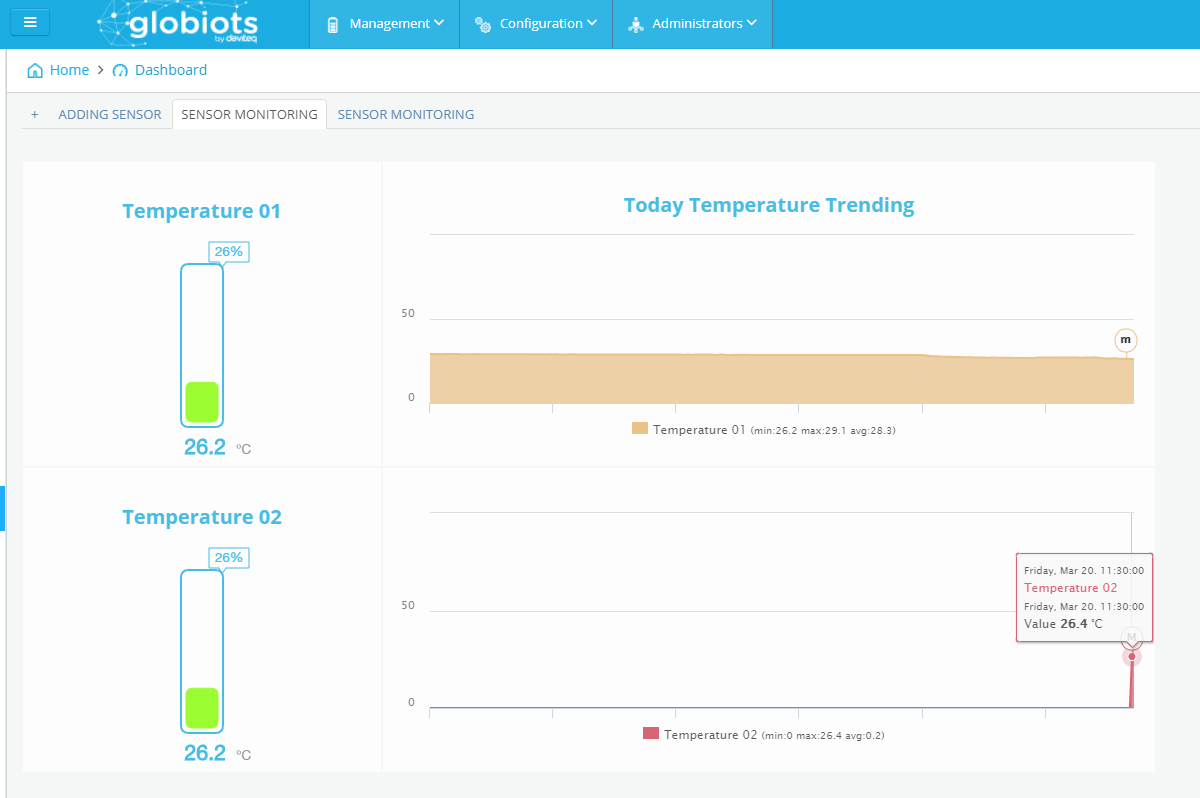

Step 3: Using iConnector, Modbus on Globiots communicating with WS433-CL (1) to write node ID of sensor node to node address id = 0 followed by node id already in “Adding Wireless sensor (in the Modbus Memmap of WS433-CL)” area.

Ex: In globiots, create a parameter with the address space x3000 then create a modbus command according to the memmap file.

- Function 3: Read holding registers

- Function 4: Read input registers

- Function 16: Preset Multiple registers

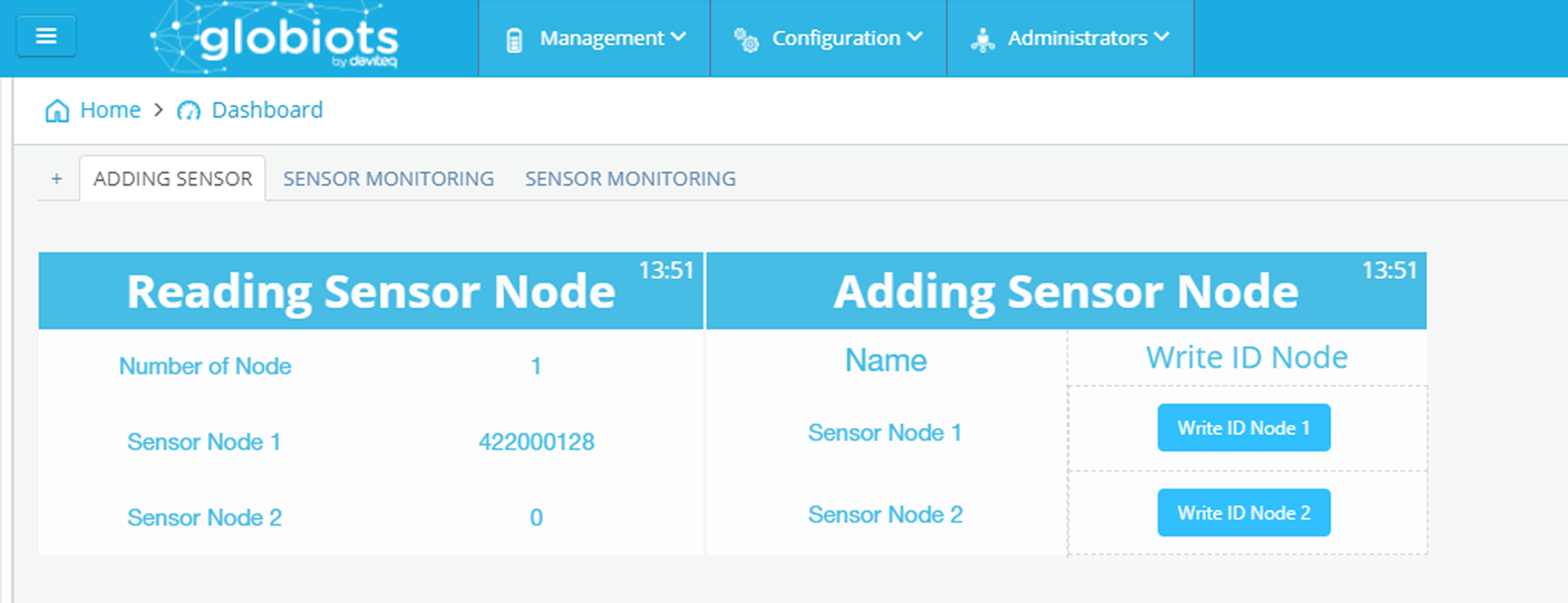

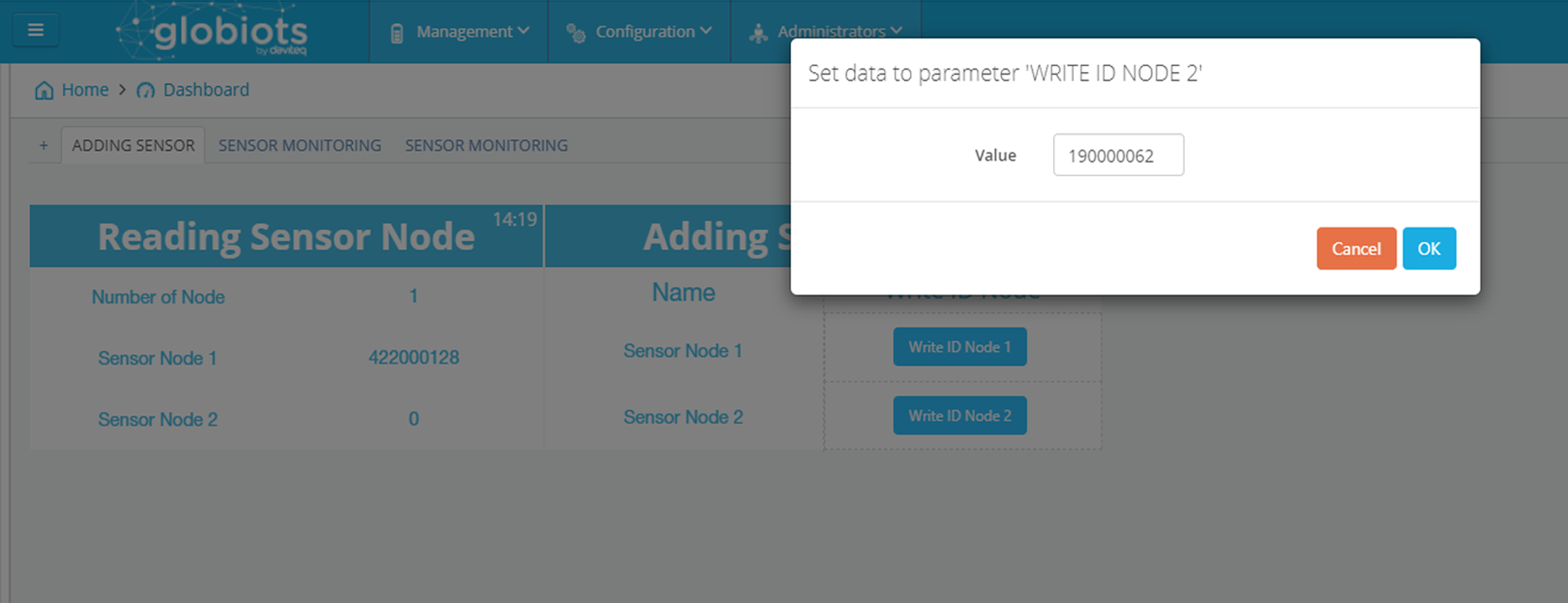

- Next add container on the dashboard, then add the parameters created to container as button "Write ID Node 2"

- Click "Write ID Node 2" to write the id of node 2 to the co-ordinator WS433-CL-04

5.2 Configuring the co-ordinator WS433-CL

- Num of Node will indicate the number of nodes managed by WS433-CL.

- Every time a node is added, the Num of Node will increase by 1.

- Every time a node is deleted, the Num of Node is reduced by 1.

- Writing Num of Node = 0 will delete all 40 node ids to 0.

- If you want to delete a node id, then write it = 0 with the Write function is 16 and the Read function is 3.

First, you need to prepare

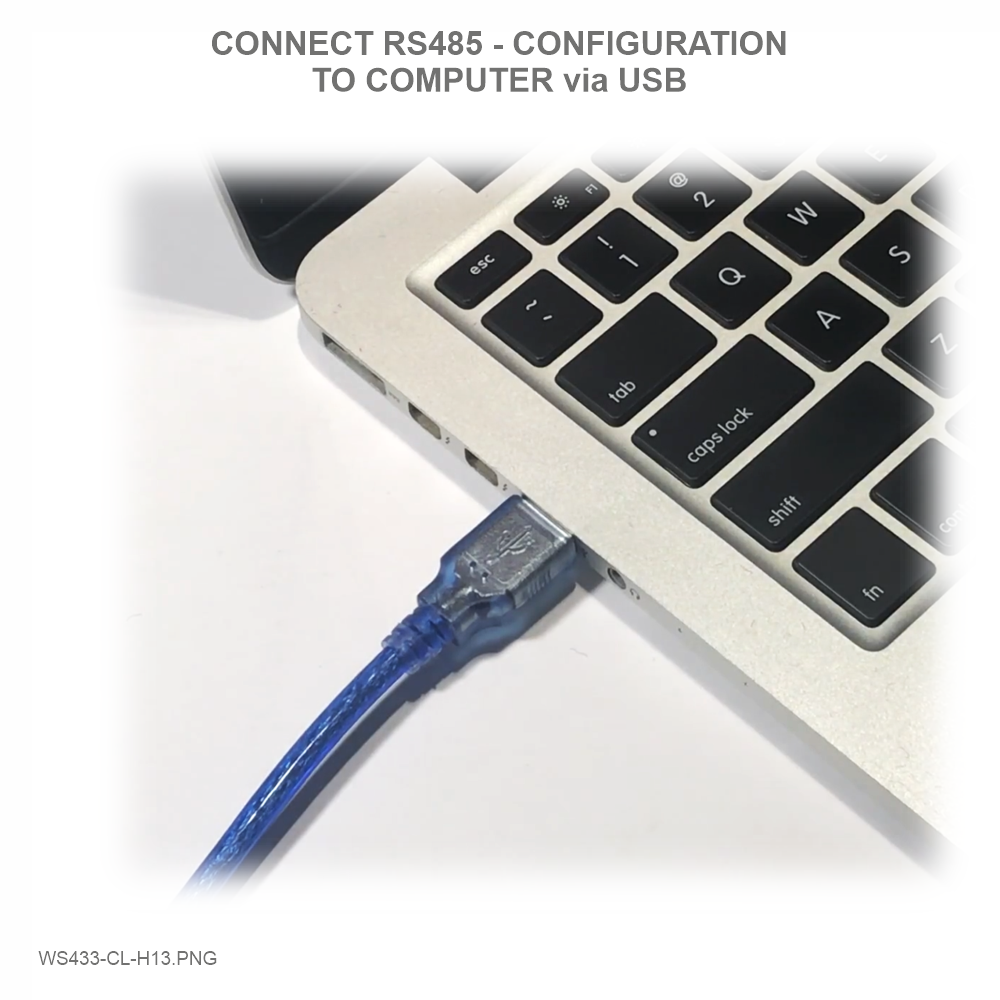

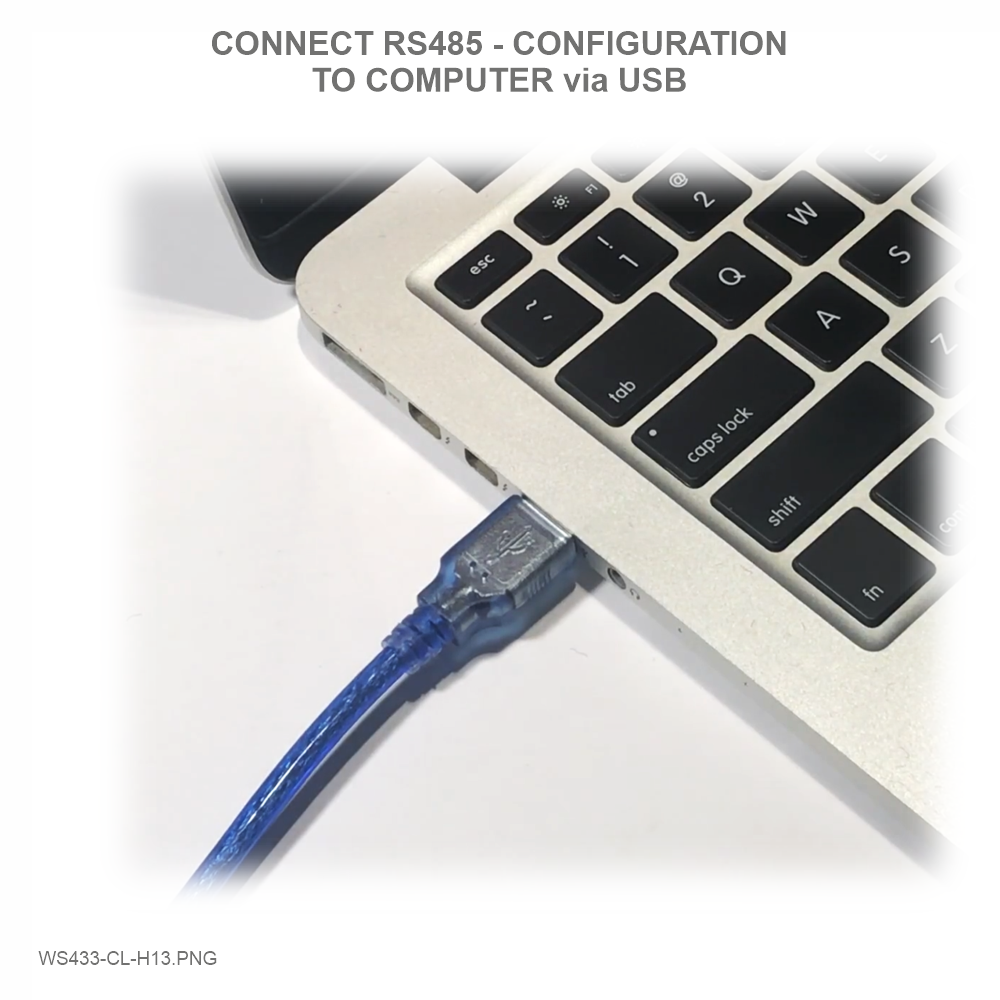

Step 1: Connect Antenna, RS485 - configuration cable and power supply co-ordinator

|

|

|

|

Step 2: Open Modbus tool on PC

- You can download Daviteq Modbus Configuration Tool with the following link:

https://filerun.daviteq.com/wl/?id=yDOjE5d6kqFlGNVVlMdFg19Aad6aw0Hs

Template File: https://filerun.daviteq.com/wl/?id=hgrjOg3wwvyrvAZ54p8iZiFpDyXTcnec

How to use the Modbus configuration software

- Unzip file and run file application "mb_master 1.1"

- Choose COM Port (the Port which is USB cable plugged in)

- Set the BaudRate: 9600, Parity: none

- Click “ Connect “ untill the Status displays “disconnected” to “connected“. It means the WS433-CL-04 is being connected with computer;

- Next, we need to import the configuration file for WS433-CL-04 by importing the csv file: Go to MENU: FILE / Import New / => select the template file (csv).

Step 2: Check information of sensor.

5.3 Hall sensor and button function

- Press and hold the push button or bring the magnet near the Hall sensor for 2s => see the LED blink once or the buzzer will ring 1 Beep => release the push button or take the magnet out to set RF data rate RF 50 kbps

- Press and hold the push button or bring the magnet near the Hall sensor for 5s => see the LED blink twice or the buzzer beep 2 Beep => release the push button or take the magnet out to set RF data rate RF 625 bps

- Press and hold the push button or bring the magnet near the Hall sensor for 10s => see the LED blinking 3 times or the buzzer buzzes 3 Beep => release the push button or take the magnet to perform the User factory reset (User factory reset = reset frequency, RF transmit power, data rate, Node ID of 40 WS, Modbus operating parameters, compare time for data status).

- If it takes more than 30 seconds, the button will be deactivated.

Reset default Co-ordinator:

- Frequency: 433.92 MHz

- RF transmit power: 15 dBm

- RF data rate: 50 kbps

- Modbus: address = 1, Baudrate = 9600, Parity = none

- Num of Node = 0, Node ID 40 nodes = 0

- Compare time: 15, 30, 45, 60, 300, 600, 900, 1800

- cmp_threshold = 630

- rssi_threshold = -25

5.4 Manage data sent from nodes (up to 40 nodes)

LED will reverse state when WS433-CL receives RF packet from sensor node.

When WS433-CL receives data packet from node then WS433_CL will send ACK confirm. If the node does not receive the ACK, it will send the data packet one more time.

5.4.1 Data packet consists of 46 bytes:

|

Parameter |

Byte Size |

Format |

Meaning |

|

Battery |

2 |

Uint16 |

|

|

1st - Parameter |

4 |

vary |

|

|

SensorStatus |

2 |

Byte |

|

|

2nd -Parameter |

4 |

vary |

|

|

Logic status of Parameter |

2 |

Uint16 |

|

|

1st - TimerUp |

4 |

Uint32 |

Calculate the cumulative time when Logic status 1 = 1. The timer value is not saved when the sensor loses power. |

|

1st - TimerDown |

4 |

Uint32 |

Calculate the cumulative time when Logic status 1 = 0. The timer value is not saved when the sensor loses power. |

|

1st - RisingEdge Counter |

4 |

Uint32 |

Calculate the total accumulated times when Logic status 1 = 1. The Counter value is not saved when the sensor loses power. |

|

1st - FallingEdge Counter |

4 |

Uint32 |

Calculate the total accumulated times when Logic status 1 = 0. The Counter value is not saved when the sensor loses power. |

|

2nd - TimerUp |

4 |

Uint32 |

Calculate the total accumulated time when Logic status 2 = 1. The timer value is not saved when the sensor loses power. |

|

2nd - TimerDown |

4 |

Uint32 |

Calculate the total accumulated time when Logic status 2 = 0. The timer value is not saved when the sensor loses power. |

|

2nd - RisingEdge Counter |

4 |

Uint32 |

Calculate the total accumulated times when Logic status 2 = 1. The Counter value is not saved when the sensor loses power. |

|

2nd - FallingEdge Counter |

4 |

Uint32 |

Tính tổng số lần cộng dồn khi Logic status 2 = 0. Giá trị Counter không có lưu khi cảm biến mất nguồn. |

5.4.2 Status bytes of sensor Node

-

Hi-Byte is error code

|

Error code |

Description |

|

0 |

No error |

|

1 |

Just exchange the sensor module but node has not been reset ==> please take out the battery for 20s then install it again to reset node to recognize the new sensor module |

|

2 |

Error, sensor port M12F shorted to GND |

|

3 |

Error, sensor port M12F shorted to Vcc |

|

4 |

Error, sensor port M12F shorted each other |

|

51 |

Check sum error of sensor port |

- Lo-Byte is sensor type

|

Sensor type |

Description |

|

1 |

Ambient temperature sensor |

|

2 |

Ambient humidity sensor |

|

3 |

Ambient differential pressure sensor |

|

4 |

Process pressure sensor |

|

5 |

1-channel AC 5A current sensor |

|

6 |

2-channel digital input with counters |

|

7 |

2-channel digital input with status detecting |

|

8 |

Ambient light sensor |

|

9 |

1-channel 0-20mA analog input |

|

10 |

Relay output 2 SPDT or 4 SPST |

|

11 |

Soil moisture sensor with I2C |

|

12 |

Soil moisture sensor with RS485 |

|

255 |

No sensor |

5.4.3 Logic status of parameters

Hi-Byte is Logic status of parameter 1

- If parameter 1's value > high threshold 1 => Hi-Byte of Logic status = 1

- If parameter 1's value < low threshold 1 => Hi-Byte of Logic status = 0

- If parameter 1 is digital => Hi-Byte of Logic status = parameter 1's value

- Timer up 1 = (Total time when Hi-Byte of Logic status = 1)

- Timer down 1 = (Total time when Hi-Byte of Logic status = 0)

- RisingEdge counter 1 = (Counter value when Hi-Byte of Logic status changes from 0 to 1)

- FallingEdge counter 1 = (Counter value when Hi-Byte of Logic status changes from 1 to 0)

Lo-Byte is Logic status of parameter 2

- If parameter 2's value > high threshold 2 => Lo-Byte of Logic status = 1

- If parameter 2's value < low threshold 2 => Lo-Byte of Logic status = 0

- If parameter 2 is digital => Lo-Byte of Logic status = parameter 2's value

- Timer up 2 = (Total time when Lo-Byte of Logic status = 1)

- Timer down 2 = (Total time when Lo-Byte of Logic status = 0)

- RisingEdge counter 2 = (Counter value when Lo-Byte of Logic status changes from 0 to 1)

- FallingEdge counter 2 = (Counter value when Lo-Byte of Logic status changes from 1 to 0)

Packet data from 40 nodes is saved to the modbus table, use the command 04 modbus RTU to read, see the "OPERATION DATA OF 40 WIRELESS SENSORS (in the Modbus Memmap of WS433-CL)"

Data status node:

|

Data status |

|

|

99 |

Have not received data from wireless sensor |

|

0 |

when data from wireless sensor just arrived in within "cmp time 1" seconds. "cmp time 1" is configurable and has a default value of 15s |

|

1 |

when data from wireless sensor just arrived in within "cmp time 2" seconds. "cmp time 2" is configurable and has a default value of 30s |

|

2 |

when data from wireless sensor just arrived in within "cmp time 3" seconds. "cmp time 3" is configurable and has a default value of 45s |

|

3 |

when data from wireless sensor just arrived in within "cmp time 4" seconds. "cmp time 4" is configurable and has a default value of 60s |

|

4 |

when data from wireless sensor just arrived in within "cmp time 5" seconds. "cmp time 5" is configurable and has a default value of 300s |

|

5 |

when data from wireless sensor just arrived in within "cmp time 6" seconds. "cmp time 6" is configurable and has a default value of 600s |

|

6 |

when data from wireless sensor just arrived in within "cmp time 7" seconds. "cmp time 7" is configurable and has a default value of 900s |

|

7 |

when data from wireless sensor just arrived in within "cmp time 8" seconds. "cmp time 8" is configurable and has a default value of 1800s |

|

8 |

when data from wireless sensor just arrived in within "cmp time 9" seconds. "cmp time 9" is configurable and has a default value of 3600s |

|

9 |

when data from wireless sensor had arrived longer than "cmp time 9" seconds. "cmp time 9" is configurable and has a default value of 3600s |

Configure the cmp time at “SETTING TIMEOUT VALUE OF DATA STATUS (in the Modbus Memmap of WS433-CL)”

- RF signal strength of node

|

RF signal strength |

|

|

0 |

RSSI < -100dBm |

|

1 |

RSSI = -80…-100dBm |

|

2 |

RSSI = -70…-79dBm |

|

3 |

RSSI = -55...-69dBm |

|

4 |

RSSI = 0…-54dBm |

- Read Data status node and RF signal strength of node of 40 nodes in the area “STATUS DATA OF 40 WIRELESS SENSORS (in the Modbus Memmap of WS433-CL)”

5.5 Control from WS433-CL to the node

For each node, there is a zone to control from the WS433-CL, including 8 registers (16 bytes), to see the starting address for each node at "CONTROL DATA OF 40 WIRELESS SENSORS (in the Modbus Memmap of WS433-CL)".

Using the modbus 16 command to write to this area, the WS433-CL will send the RF control down to the node, then the node sends back the ACK packet, which contains data from the sending node after executing the command. control.

8 control registers for WS433-RL sensor node:

|

Description |

#reg |

Format |

Explanation |

|

Control Relay 1 of sensor Node |

1 |

uint16 |

0: turn off relay 1 1: turn on relay 1 |

|

Control Relay 2 of sensor Node |

1 |

uint16 |

0: turn off relay 2 1: turn on relay 2 |

|

Control Relay 3 of sensor Node |

1 |

uint16 |

0: turn off relay 3 1: turn on relay 3 |

|

Control Relay 4 of sensor Node |

1 |

uint16 |

0: turn off relay 4 1: turn on relay 4 |

|

spare |

4 |

|

|

5.6 Synchronizing configuration between WS433-CL and node:

For each node, there is a configuration synchronous zone from WS433-CL, consisting of 40 registers (80 bytes), see the start address for each node at "ADVANCED CONFIG (in the Modbus Memmap of WS433-CL)".

|

# of register |

Description |

Value Range |

Default |

Format |

Explanation |

|

1 |

Cycle_wakeup |

1-3600(s) |

120 |

uint16 |

Every time interval of Cycle_wakeup, sensor node would ONLY send data to co-ordinator if the new measured value was changed more than the Delta value of the last measured value. Default Cycle_wakeup is 120 seconds |

|

1 |

Cycle_healthsta |

60-7200(s) |

600 |

uint16 |

Every time interval of Cycle_healthsta, sensor node will absolutely send data to co-ordinator regardless any condition |

|

2 |

Co-ordinator id |

0 |

uint32 |

Configure the ID number of Co-ordinator that wireless sensor want to connect to the Co-ordinator when only adding the sensor manually |

|

|

2 |

Radio frequency |

433.05-434.79, 433 Mhz |

433.92 |

float |

Configure the operating frequency of wireless sensor by Co-ordinator, should be configured from 433.05-434.79 MHz, only for advanced users |

|

1 |

Tx power |

-10,10,15 |

15 |

int16 |

Configure the RF power of wireless sensor by Co-ordinator, only for advanced users |

|

1 |

Data rate RF |

0-1 |

0 |

uint16 |

Configure the air data rate of wireless sensor by Co-ordinator, only for advanced users |

|

2 |

a1 |

1 |

float |

Scale value of parameter_1 = (a1 * Raw sensor value of parameter_1) + b1. For sensor value scale |

|

|

2 |

b1 |

0 |

float |

Scale value of parameter_1 = (a1 * Raw sensor value of parameter_1) + b1. For sensor value scale |

|

|

2 |

a2 |

1 |

float |

Scale value of parameter_2 = (a2 * Raw sensor value of parameter_2) + b2. For sensor value scale |

|

|

2 |

b2 |

0 |

float |

Scale value of parameter_2 = (a2 * Raw sensor value of parameter_2) + b2. For sensor value scale |

|

|

2 |

Delta_1 |

0 |

float |

Delta value, this is the threshold to allow sending data to co-ordinator when the new value of parameter 1 is changed from the last value a delta value which is higher than the threshold. |

|

|

2 |

High_threshold_1 |

0 |

float |

High threshold value for parameter 1 |

|

|

2 |

Low_threshold_1 |

0 |

float |

Low threshold value for parameter 1 |

|

|

2 |

High_threshold_2 |

0 |

float |

High threshold value for parameter 2 |

|

|

2 |

Low_threshold_2 |

0 |

float |

Low threshold value for parameter 2 |

|

|

14 |

spare |

|

|

|

Each type of WS node will have different configurations |

When the WS433-CL power is turned on, the node's configuration will be read from flash, sync status = 99.

When the battery is plugged in or the power is turned on, the node sends the registration packet to the WS433-CL which contains the node's configuration. Configuration from the node will be overwritten on the configuration area on WS433-CL => Save flash => Sync completed, sync status = 0.

When users want to change the configuration on the node, use modbus RTU command 16 write to the configuration area on WS433-CL ==> sync status = 1: WS433-CL wait for the node to send data. When the node sends data, WS433-CL will send configuration to node, node sends back authentication ACK containing this new configuration ==> sync status = 0: sync configuration OK, users should read this new configuration section right.

Read the Sync status of 40 nodes in the "STATUS DATA OF 40 WIRELESS SENSORS (in the Modbus Memmap of WS433-CL)" area.

|

Sync status |

|

|

0 |

sync ok |

|

1 |

waiting for sync |

|

99 |

power-on-reset default |

5.7 Configuration of RF operation parameters

- Frequency 433.05 - 434.79Mhz, default 433.92Mhz

- RF transmit power: 10 dBm, 15dBm (default)

- Data rate of RF: 50kbps (default), 625bps

=> When changing the configuration of RF parameters, it must be reset for the WS433 board to operate under the new RF configuration. However, if you use the push button or the Magnetic sensor to change the RF data rate, there is no need to reset the board

5.7.1 The procedure for changing the frequency for the sensor and Co-or is as follows:

- Step 1: Use the Modbus Tool to change the frequency recording of each sensor, then remove the sensor battery, wait 10 seconds and reinsert it, then wait for 30 seconds, it will receive the configuration from Co-o, then confirm that the frequency change is successful. How to check on Co-or by Modbus Tool software.

- Step 2: Remove that sensor battery and set it aside;

- Step 3: Continue to step 1 for the next sensor;

- Step 4: After changing the frequency for all sensors, finally change the frequency for Co-or by using the Modbus Tool to write down, then turn off the power of co-or for 10 seconds and then power again, it will run at the new frequency, and connect to the sensor at the new frequency;

5.7.2 Change data rate: See more at section "5.3 Hall sensor and button function"

5.8 Modbus communication

Configuration:

- Protocol: Modbus RTU

- Address: 1 - 247

- Baud rate: 9600 , 19200

- Parity: none, even, odd

- Stop bits: 1

6. Installation

6.1 Mounting bracket installation

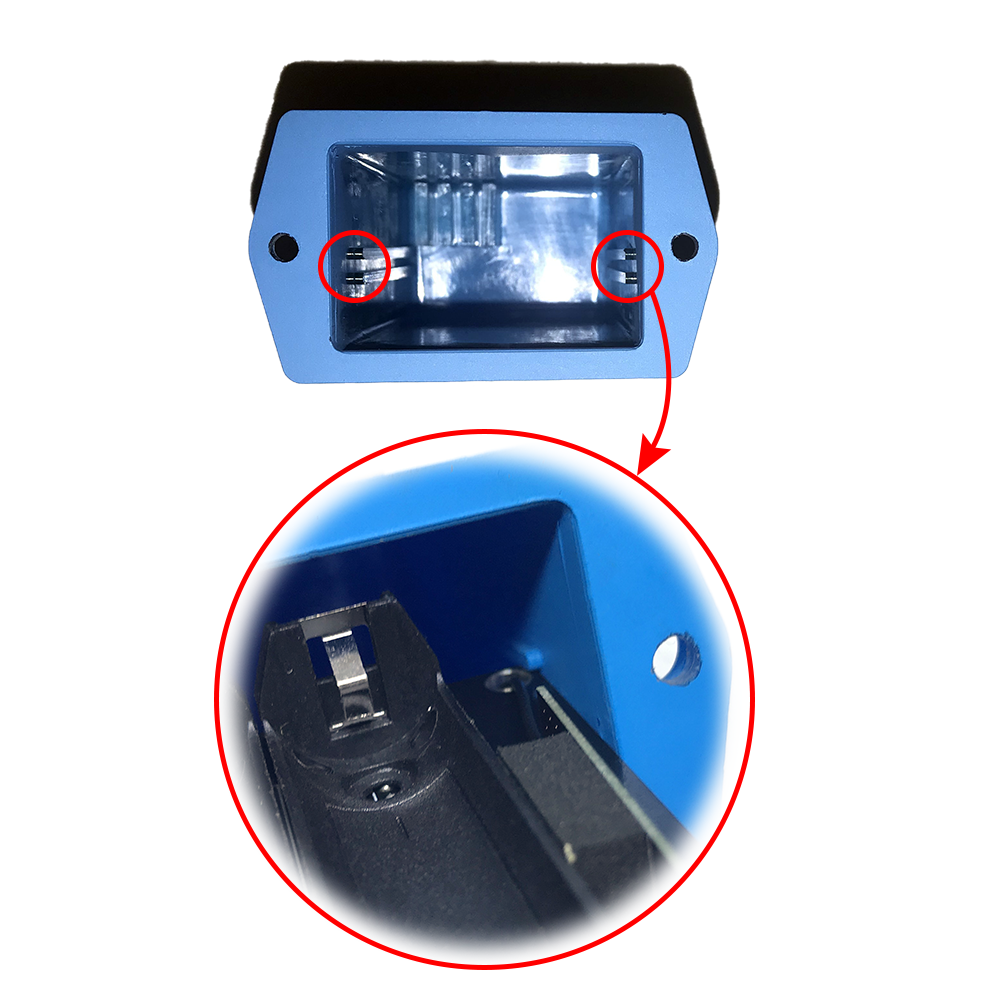

The mounting bracket is made from hard metallic material. Following to these steps as the below picture

Insert the top plastic housing and locking by L hex key

(NOTE: When reinstalling the cover, pay attention to put the PCB edge into the middle slot of the box inside as shown below)

6.2 Installation location

To maximize the distance of transmission, the ideal condition is Line-of-sight (LOS) between the two modules. In real life, there is no LOS condition. However, the two modules still communicate each other, but the distance will be reduced significantly.

Therefore, to maximize the transmission distance, please pay attention to the following conditions:

- DO NOT install the wireless module inside a complete metallic box or housing. The signal can not pass through metallic wall;

- This wireless module would be installed a semi-metallic box, because the RF signal can pass through the non-metal wall/are;

- The best case is to install the wireless module inside or Non-metallic box;

Some non-metallic materials: plastic, glass, wood, leather, concrete, cement…

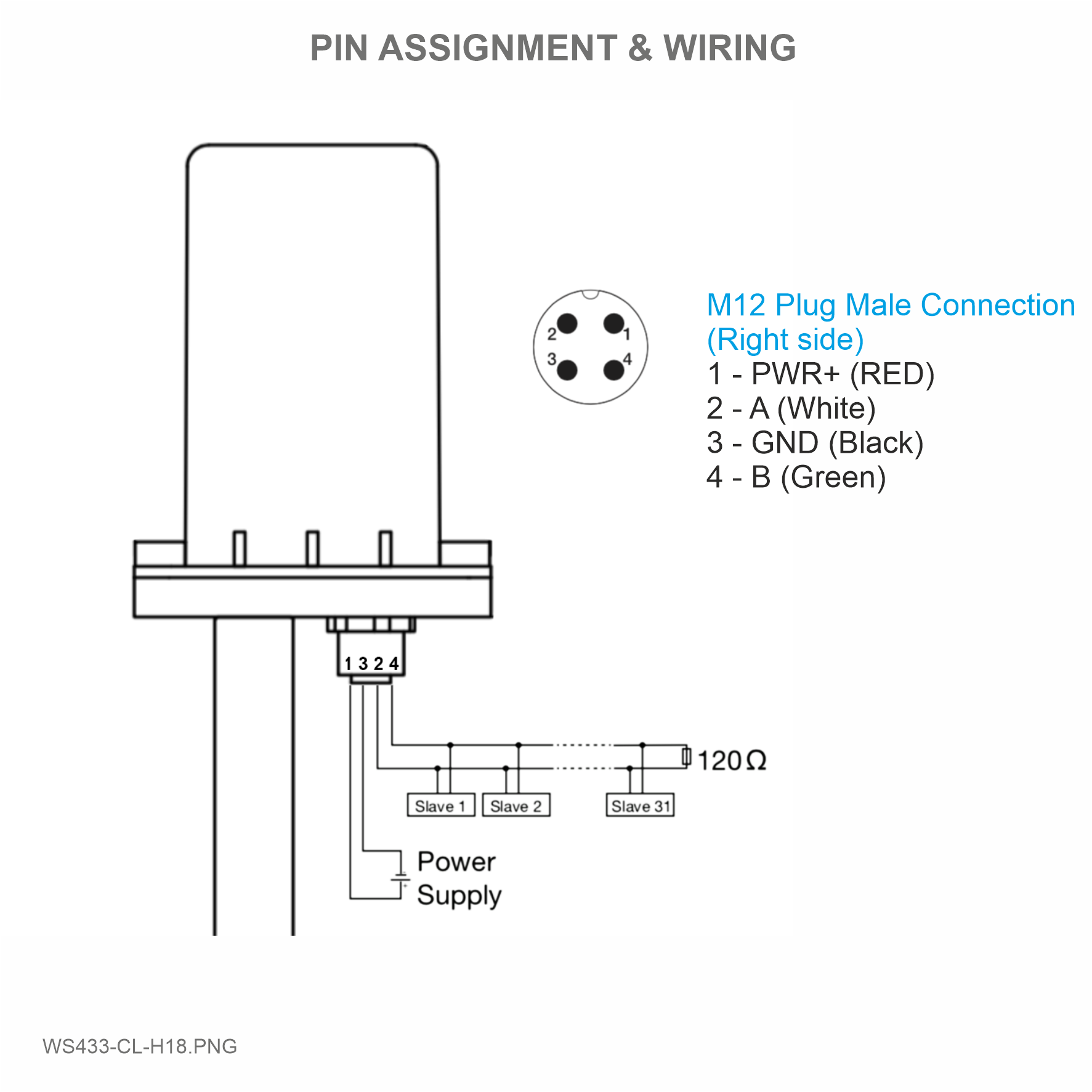

6.3 IO Wiring & Sensor installation

|

|

|

|

7. Troubleshooting

| No. | Phenomena | Reason | Solutions |

| 1 | Cannot read modbus |

|

|

| 2 | Failed to add auto sensor |

|

|

| 3 | Read modbus normal health values but read the data of the node, all are 0 |

|

|

| 4 | The node's data has no data of prm1 and prm2 |

|

|

8. Support contacts

|

Manufacturer Daviteq Technologies Inc Email: info@daviteq.com | www.daviteq.com

|

Distributor in Australia and New Zealand Templogger Pty Ltd Tel: 1800 LOGGER Email: contact@templogger.net |

No Comments