USER GUIDE FOR EX D APPROVED SIGFOX READER FOR ELECTRONIC VOLUME CORRECTOR WSSFCEX-EVC

THIS IS OBSOLETE MANUAL

Please access https://www.iot.daviteq.com/wireless-sensors for updated manual

| WSSFCEX-EVC -MN-EN-01 |

MAY-2021 |

This document is applied for the following products

| SKU | WSSFCEX-EVC | HW Ver. | 1.2 | FW Ver. | 1.2 |

| Item Code |

WSSFCEX-EVC-9-MINI-MAX-Z1 |

SIGFOX MERCURY EVC MINI-MAX READER, ATEX EXD APPROVAL ZONE 1/2, M20 CABLE GLAND WITH 10M SHIELDED CABLE AND AMP CONNECTOR, IP67 CAST ALUMINUM HOUSING, TYPE AA BATTERY 1.5VDC, RC2-RC3-RC4-RC5 ZONES | |||

| WSSFCEX-EVC-8-MINI-MAX-Z1 | SIGFOX MERCURY EVC MINI-MAX READER, ATEX EXD APPROVAL ZONE 1/2, M20 CABLE GLAND WITH 10M SHIELDED CABLE AND AMP CONNECTOR, IP67 CAST ALUMINUM HOUSING, TYPE AA BATTERY 1.5VDC, RC1-RC6-RC7 ZONES | ||||

1. Functions Change Log

| HW Ver. | FW Ver. | Release Date | Functions Change |

| 1.2 | 1.2 | SEP-2020 |

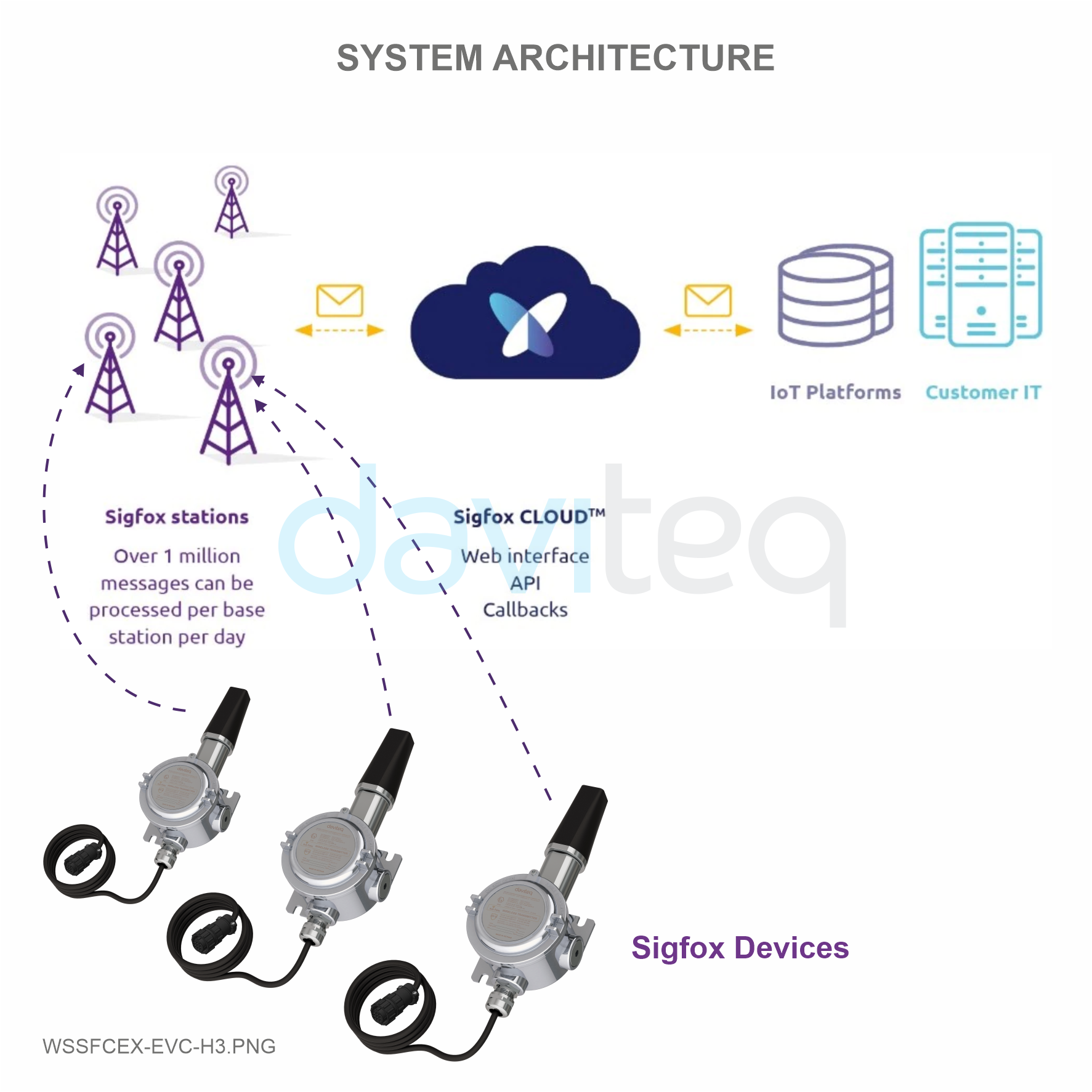

2. Introduction

WSSFCEX-EVC is the Sigfox reader to read process data from Electronics Volume Corrector (EVC) with Exd approval for installation in Zone 1, Zone 2 or Safe Zone, and it can connect to any EVC with Modbus RTU communication or Mercury proprietary protocol. It will automatically read those parameters from EVC: corrected volume, un-corrected volume, gas pressure, gas temperature...With Ultra-low-power design and smart firmware allow the Sigfox device can last up to 10 years with single 2 x AA batteries (depends on configuration). It can supports all regions of Sigfox network in over the World, RC1, RC2, RC3, RC4, RC5, RC6, RC7. Typical applications are monitoring of Gas metering skids, Gas metering system for Natural Gas, LNG, CNG...

3. Specification

| Type of EVC to connect | Connect to any Electronic Volume Corrector with Modbus RTU or Mercury protocol |

| Connector | Standard is AMP connector to work with Mercury Mini-Max EVC, for other EVC pls specify when ordering |

| Cable length | 10m shielded cable |

| Sigfox zones | select RC2-RC3-RC4-RC5 or RC1-RC6-RC7 |

| Antenna | N-male type external Antenna |

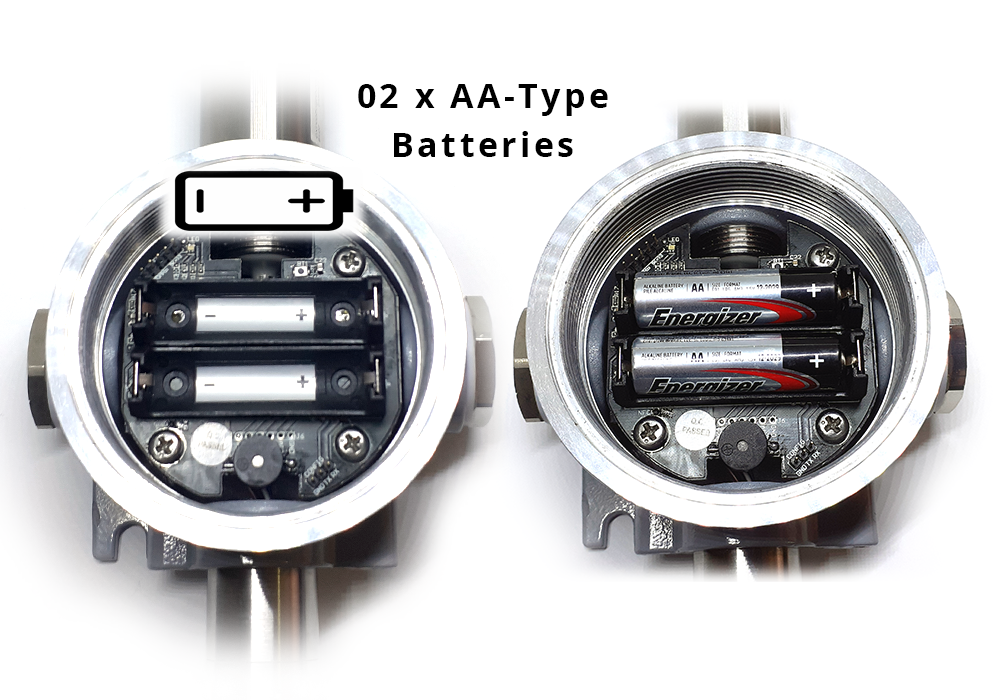

| Battery | 02 x AA Type 1.5VDC, working time up to 10 years (depends on configuration) |

| ATEX Certificates | IMQ 14 ATEX 005 X and TÜV CY 18 ATEX 0206158 X |

| Marking | ATEX II 2G Ex db IIC T5/T6 Gb and ATEX II 2D Ex tb IIIC T100/T85°C Db |

| Directive | ATEX 2014/34/EU |

| Standards | IEC-EN60079-0 IEC-EN60079-1 IEC-EN60079-31 |

| Applicable zones | Zone 1 - 21 (gas) and Zone 2 - 22 (dust) |

| Ambient working temperature | -40°C..+85°C |

| Housing | Cast aluminium, powder coated, IP66 |

| Mounting | wall mounting holes |

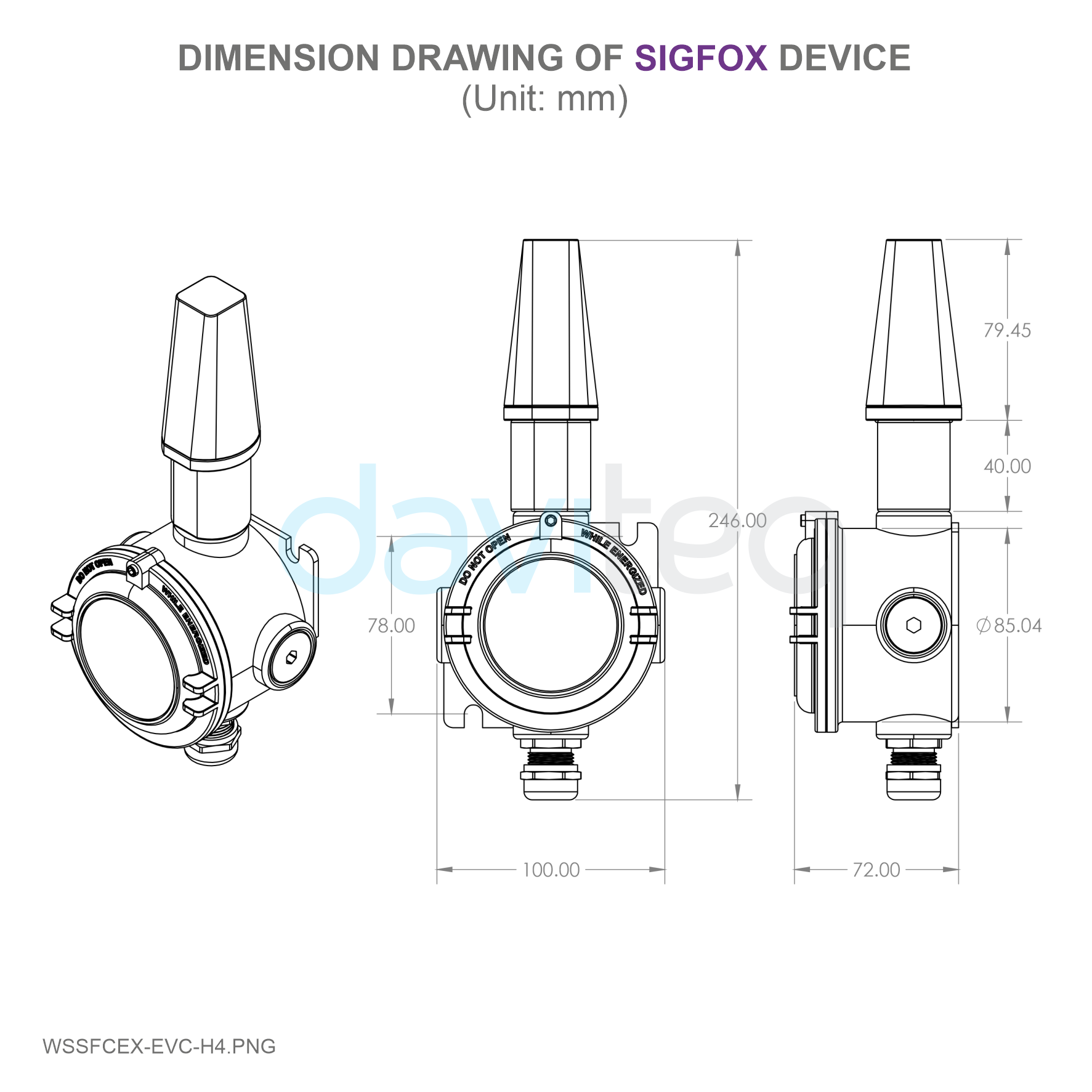

| Product dimensions | H210xW100XD72 |

| Net weight | 1.5 kgs |

| Packaging dimension | W160 x D150 x H250 mm |

| Gross weight | < 1.6 kgs |

4. Dimensions

5. Operation Principle

Upon power on, the Sigfox node has 60 seconds to wait for off-line configuration (via cable with ModbusRTU protocol).

After that, Sigfox node will send the first message to Base station.

Then during the operation, there are 03 cases of sending data to base station:

- When the sensor sampling time interval is reached, the Sigfox node will read the data from Input or sensor and performing the calculation. After that it will check calculated value with alarm thresholds. If the calculated was out off the threshold values (Lo or Hi), called alarm, and the number of times of alarm did not pass the limit of number of alarms, then it will send data to Base station immediately;

NOTE:

Once sending the data to base station by this alarm event, the timer of sending time interval will be reset; - When the sending time interval is reached, it will send data to Base station immediately, regardless of value;

- By using the magnet key, the Sigfox node can be triggered to send data to base station immediately. There will be a beep sound from the buzzer meaning the data has been sent.

NOTE:

Once sending the data to base station by the magnet key, the timer of sending time interval will be reset;

The shortest time interval between the two manual triggers is 15s. if shorter than 15s, there will be no data sending and you will not hear the beep sound.

|

|

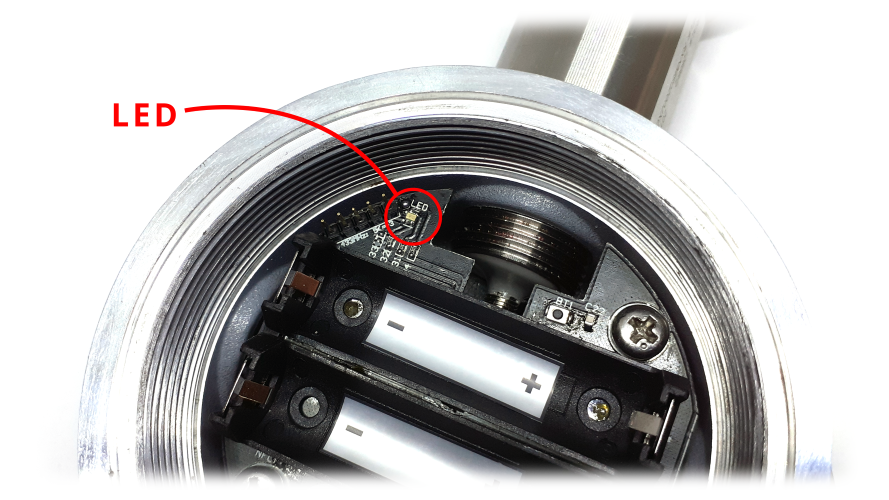

5.1 LED meaning

- RC1: RED colour

- RC2: GREEN colour

- RC4: BLUE colour

5.2 Button Function

5.2.1 Menu configuration

There are 3 configuration menus: tx_repeat, downlink_flag, radio configuration.

5.2.1.1 tx_repeat

Press and hold the button 2s -> When the Red LED is on, it means entering the tx_repeat configuration menu. Then release to configure it.

Press to configure. After pressing if the Red LED flashes once, tx_repeat = 0 (send 1 time). After pressing if the Red LED blinks twice, it is tx_repeat = 1 (send 3 times).

5.2.1.1 downlink_flag

Press and hold the button 5s -> When the Green LED is on, it means entering the downlink_flag configuration menu. Then release to configure it.

Press to configure. After pressing if the Green LED flashes once, it is downlink_flag = 0 (downlink is not allowed). After pressing if the Red LED blinks twice, it is downlink_flag = 1 (downlink is allowed).

5.2.1.1 radio configuration

Press and hold the button 10s -> Blue LED is on, it means entering the Radio Configuration menu. Then release to configure it.

Press to configure. After pressing if the Blue LED blinks once, it is Radio Configuration = 1. After pressing if the Blue LED flashes twice, it is Radio Configuration = 2. After pressing if the Blue LED flashes 4 times, it is Radio Configuration = 4.

5.2.2 Exit the menu:

There are 3 ways to exit the menu:

- Press and hold for 3s, the LED turns off to exit the menu;

- Wait 30 seconds, then exit the menu;

- Take out the battery, it all starts over (outside the menu)).

5.3 RC technical details

Sigfox Radio Configuration (RC) defines the radio parameters in which the device shall operate: Sigfox operating frequencies, output power, spectrum access mechanism, throughput, coexistence with other radio technologies, etc.

Each radio configuration includes 4 uplink classes: 0u, 1u, 2u, and 3u.

The Sigfox network globally works within the ranges from 862 to 928 MHz. But not all RCs require such a wide range of operation.

| RC1 | RC2 | RC3 | RC4 | RC5 | RC6 | RC7 | |

|---|---|---|---|---|---|---|---|

| Uplink center frequency (MHz) | 868.130 | 902.200 | 923.200 | 920.800 | 923.300 | 865.200 | 868.800 |

| Downlink center frequency (MHz) | 869.525 | 905.200 | 922.200 | 922.300 | 922.300 | 866.300 | 869.100 |

| Uplink data rate (bit/s) | 100 | 600 | 100 | 600 | 100 | 100 | 100 |

| Downlink data rate (bit/s) | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Sigfox recommended EIRP (dBm) | 16 | 24 | 16 | 24 | 14 | 16 | 16 |

| Specifics | Duty cycle 1% * | Frequency hopping ** | Listen Before Talk *** | Frequency hopping ** | Listen Before Talk *** | Duty cycle 1% * |

* Duty cycle is 1% of the time per hour (36 seconds). For an 8 to 12 bytes payload, this means 6 messages per hour, 140 per day.

** Frequency hopping: The device broadcasts each message 3 times on 3 different frequencies. Maximum On time 400 ms per channel. No new emission before 20 s.

*** Listen Before Talk: Devices must verify that the Sigfox-operated 200 kHz channel is free of any signal stronger than −80 dBm before transmitting.

Sigfox’s high limit EIRP recommendation is included in each column although regulations sometimes allow for more radiated power than the Sigfox recommendation.

Sigfox’s recommendation is set to comply with the Sigfox technological approach of:

- Low current consumption

- Balanced link budget between uplink and downlink communication

5.4 Payload Data

The following is the format of payload data will be sent to Sigfox server.

5.4.1 Payload data 12 bytes sent hourly

|

Sensor type (1 byte) |

Status + Interval Avg Pressure + Interval Avg Temperature (3 bytes) |

Corrected Volume (4 bytes) |

Uncorrected Volume (4 bytes) |

|

Data |

Size |

Bit |

Format |

Meaning |

|

Sensor type |

1 byte |

all |

Uint8 |

Sensor type = 0x16 means Sigfox Node with EVC sensor type = 0xFF means no sensor. |

|

Status: battery level |

2 bits |

Bit 23 and 22 |

|

Battery capacity in 04 levels

|

|

Status: error |

2 bits |

Bit 21 and 20 |

|

Node status

|

|

Interval Avg Pressure (bar) |

10 bits |

Bit 19 to 10 |

Uint16 |

X Real Interval Avg Pressure value = X Interval Avg Pressure value / 10 (0.0 to 102.3bar) |

|

Interval Avg Temperature (℃) |

10 bits |

Bit 9 to 0 |

Uint16 |

Y Real Interval Avg Temperature value = Y Interval Avg Temperature value / 10 (0.0 to 102.3℃ ) |

|

Corrected Volume(m3) |

4 bytes |

all |

Uint32 |

Corrected Volume |

|

Uncorrected Volume(m3) |

4 bytes |

all |

Uint32 |

Uncorrected Volume |

FOR EXAMPLE

Raw data: 0x16819FF60156C78600238415

Explain:

- Sesor type : 0x16

- Status + Interval Avg Pressure + Interval Avg Temperature : 0x819FF6 = 0b100000011001111111110110

-

- Status battery level : 0b10 battery level 3 (60%)

- Status error : 0b00 Node status no error

- Interval Avg Pressure : 0b0001100111 = 103 => Interval Avg Pressure = 10.3 (bar)

- Interval Avg Temperature : 0b1111110110 = 1014 => Interval Avg Temperature = 101.4 (℃)

-

- Corrected Volume : 0x0156C786 = 22464390

- Uncorrected Volume : 0x00238415 = 02327573

5.4.2 Payload battery packet sent daily 4 bytes

|

Sensor type (1 byte) |

Status (1 byte) |

Battery Voltage (2 bytes) |

Meaning of Data in the Payload

|

Data |

Size |

Bit |

Format |

Meaning |

|

Sensor type |

1 byte |

all |

Uint8 |

Sensor type = 0x16 means Sigfox Node with EVC sensor type = 0xFF means no sensor. |

|

Status: battery level |

2 bits |

Bit 7 and 6 |

|

Battery capacity in 04 levels 11: battery level 4 (99%) 10: battery level 3 (60%) 01: battery level 2 (30%) 00: battery level 1 (10%) |

|

Status: error |

2 bits |

Bit 5 and 4 |

|

Node status 01: error 00: no error |

|

Status : reserved |

4 bits |

Bit 3 to 0 |

|

0000 |

|

Battery Voltage (V)

|

2 bytes |

all |

Uint16 |

X Real Battery Voltage of EVC = X Real Battery Voltage of EVC / 100 |

FOR EXAMPLE

Raw data: 0x16800252

Explain:

- Sesor type : 0x16

- Status : 0x80 = 0b10000000

-

-

Status battery level : 0b10 battery level 3 (60%)

-

Status error : 0b00 Node status no error

- Status reserved : 0000

-

-

- Battery Voltage : 0x0252 = 594 => Battery Voltage = 5.94 (V)

5.4.3 Payload for downlink

Length is 8 bytes

|

Prm_adr (1 byte) |

Prm_len (1 byte) |

Prm_value (6 bytes) |

|

Prm_name |

Prm_adr |

Prm_len |

Comment |

|

cycle_send_data |

18 |

4 |

|

6. Configuration

DANGER:

DO NOT OPEN THE COVER AT HAZARDOUS LOCATION!

ONLY OPEN COVER FOR TROUBLE SHOOTING AND CONFIGURATION IN SAFE AREA!

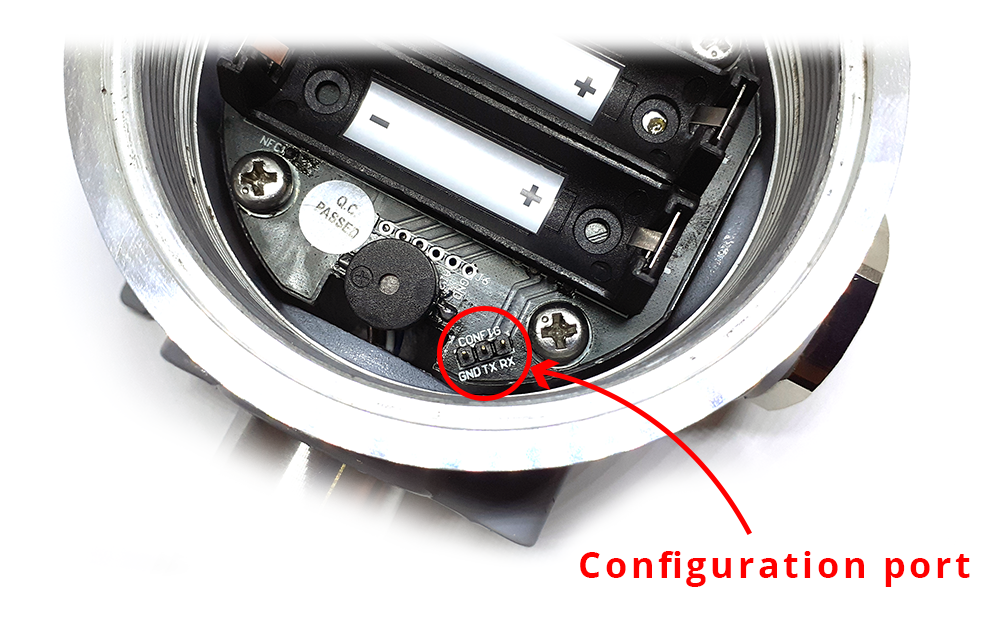

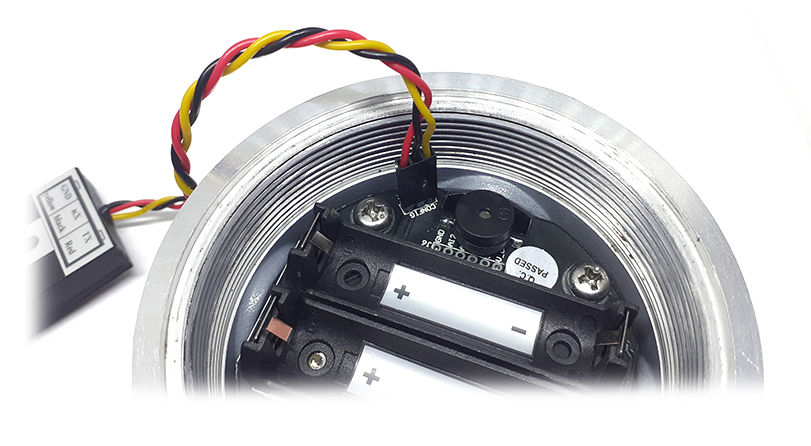

Using the configuration cable to connect to the sensor as below picture.

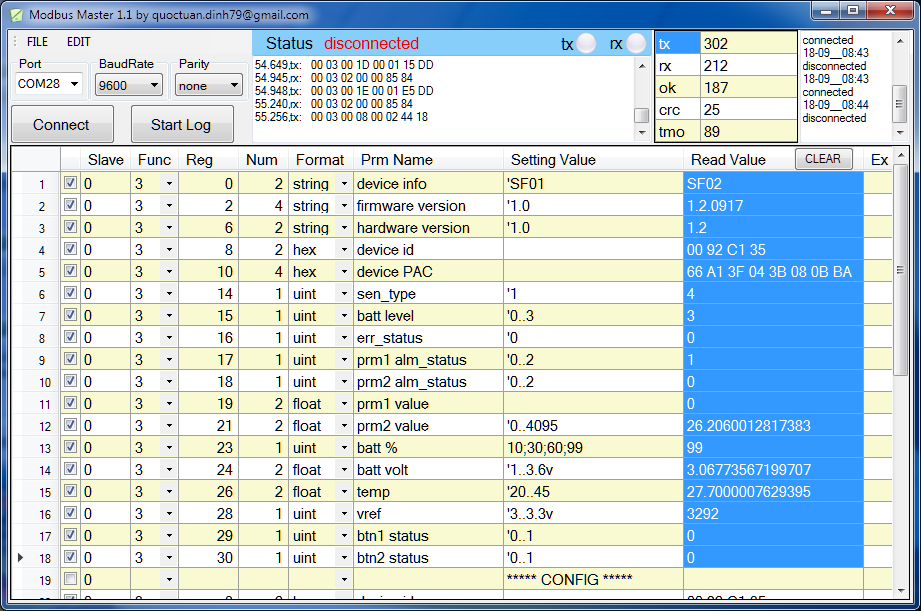

Serial port configuration on computer: 9600 baud, None parity, 1 stop bit.

Reading data by Function 3.

Writing data by Function 16.

During connection with Modbus configuration tool, the Sigfox node will send all data in realtime: Battery, Battery level, Vref, Button status, reed switch status, PCB temperature, Measured value, alarm status.

Step to configure & check data:

NOTE:

The Modbus configuration can be done in the first 60s after power up the Sigfox node. After 60s, if user can not finish the configuration, user need to reset the power of Sigfox node again, by removing battery in at least 15s.

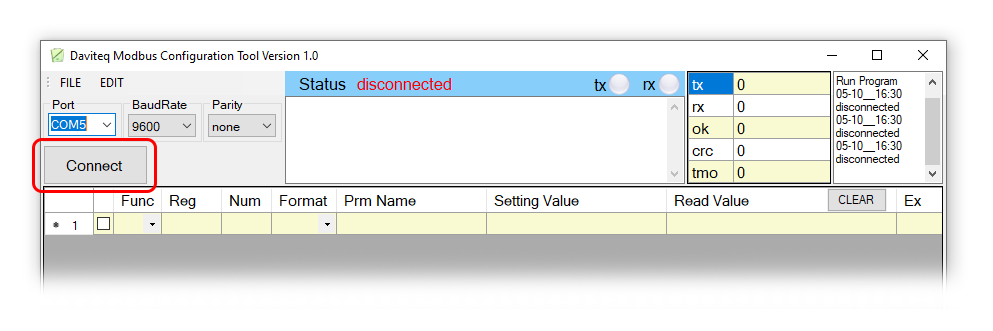

Step 1: Install the Modbus Configurator Software in the link below

https://filerun.daviteq.com/wl/?id=qK0PGNbY1g1fuxTqbFW9SXtEvCw7bpc6

How to use the Modbus configuration software

Step 2: Plug the configuration cable to computer via USB port and install the driver;

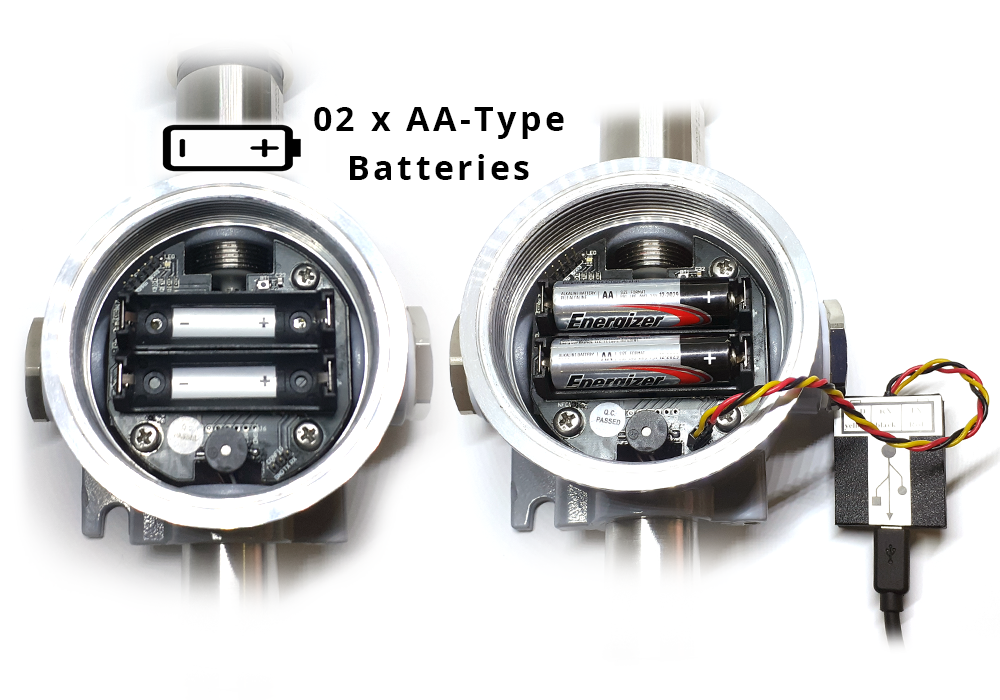

Step 3: Open the housing;

|

|

Step 4: Plug the connector to the configuration port;

| Red | Tx |

| Black | Rx |

| Yellow | GND |

Tx on cable will go with Rx on sensor and vice versa.

Step 5: Insert the battery;

ATTENTION:

REVERSED POLARITY OF BATTERIES IN 10 SECONDS CAN DAMAGE THE SENSOR CIRCUIT!!!

Step 6: Import the configuration file by importing the csv file: Go to MENU: FILE / Import New / => select the file with name CONFIGURATION TEMPLATE FILE FOR SIGFOX FW1.9.3.csv (in the link below). Then click Connect;

CONFIGURATION TEMPLATE FILE FOR SIGFOX WSSFCEX-EVC.csv

| Modbus Register (Decimal) | Modbus Register (Hex) | Function Code | # of Registers | Description | Range | Default | Format | Property | Comment |

| 0 | 0 | 3 | 2 | device info | string | Read | Product name | ||

| 2 | 2 | 3 | 4 | firmware version | 1.0 | string | Read | ||

| 6 | 6 | 3 | 2 | hardware version | 1.0 | string | Read | ||

| 8 | 8 | 3 | 2 | device ID | hex | Read | Product ID | ||

| 10 | A | 3 | 4 | device PAC | hex | Read | Product PAC | ||

| 14 | E | 3 | 1 | sen_type | 1-255 | uint16 | Read | Sensor or Input Type | |

| 15 | F | 3 | 1 | batt level | 0-3 | uint16 | Read | Battery level | |

| 16 | 10 | 3 | 1 | err_status | 0-1 | uint16 | Read | Sensor error code | |

| 17 | 11 | 3 | 1 | prm1 alm_status | 0-2 | uint16 | Read | Alarm status of 1st parameter | |

| 18 | 12 | 3 | 1 | prm2 alm_status | 0-2 | uint16 | Read | Alarm status of 1st parameter | |

| 19 | 13 | 3 | 2 | prm1 value | float | Read | 1st calculated value | ||

| 21 | 15 | 3 | 2 | prm2 value | float | Read | 2nd calculated value | ||

| 23 | 17 | 3 | 1 | batt % | 10%, 30%, 60%, 99% | uint16 | Read | Battery % | |

| 24 | 18 | 3 | 2 | batt volt | 0-3.67 vdc | float | Read | Battery Voltage | |

| 26 | 1A | 3 | 2 | temp | oC | float | Read | RF module temperature | |

| 28 | 1C | 3 | 1 | vref | 0-3.67 vdc | uint16 | Read | Vref of RF Module | |

| 29 | 1D | 3 | 1 | btn1 status | 0-1 | uint16 | Read | Button status, 0: released, 1: pressed | |

| 30 | 1E | 3 | 1 | btn2 status | 0-1 | uint16 | Read | Reedswitch status, 0: opened, 1: closed |

| Modbus Register (Decimal) | Modbus Register (Hex) |

Function Code (Read) |

Function Code (Write) |

# of Registers | Description | Range | Default | Format | Property | Comment |

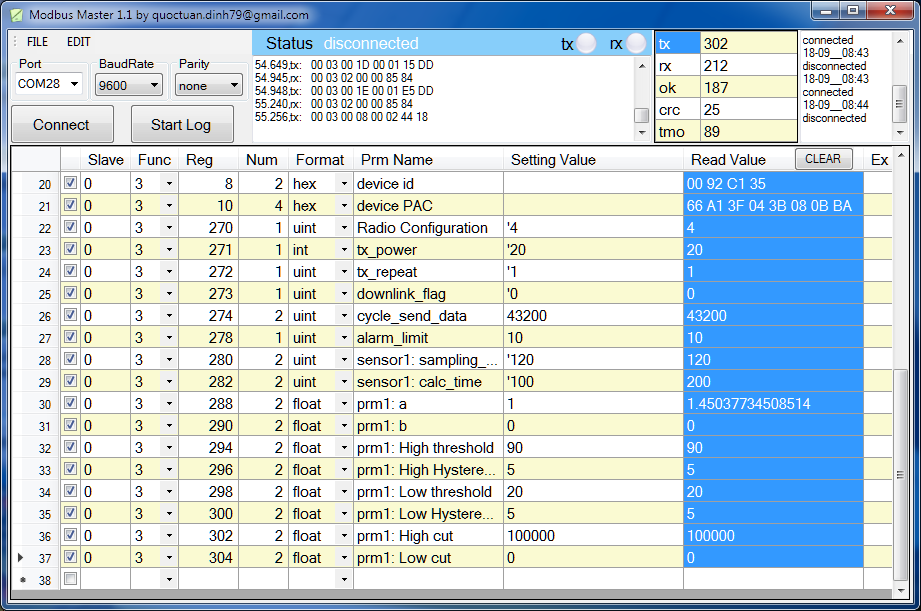

| 256 | 100 | 3 | 16 | 1 | modbus address | 1-247 | 1 | uint16 |

Read/ Write |

Modbus address of device |

| 257 | 101 | 3 | 16 | 1 | modbus baudrate | 0-1 | 0 | uint16 |

Read/ Write |

Baudrate: 0: 9600, 1: 19200 |

| 258 | 102 | 3 | 16 | 1 | modbus parity | 0-2 | 0 | uint16 |

Read/ Write |

Parity: 0: none, 1: odd, 2: even |

| 259 | 103 | 3 | 16 | 9 | serial number | string |

Read/ Write (PW) |

Product S/N | ||

| 268 | 10C | 3 | 16 | 2 | password for setting | uint32 |

Read/ Write |

Password for setting | ||

| 270 | 10E | 3 | 16 | 1 | Radio Configuration | 1-6 | 4 | uint16 |

Read/ Write |

RC zones selection 1..6 is RCZ1 .. RCZ6 |

| 271 | 10F | 3 | 16 | 1 | tx_power | 20 | int16 |

Read/ Write |

RF Tx power | |

| 272 | 110 | 3 | 16 | 1 | tx_repeat | 0-1 | 1 | uint16 |

Read/ Write |

Number of repeat, 0: 1 time, 1: 3 repeats |

| 273 | 111 | 3 | 16 | 1 | downlink_flag | 0-1 | 0 | uint16 |

Read/ Write |

1: enable Downlink, 0: disable Downlink (Fw v1.0 hasn't got Downlink function) |

| 274 | 112 | 3 | 16 | 2 | cycle_send_data | 3600 | uint32 |

Read/ Write |

Data sending cycle, in seconds |

7. Installation

7.1 Locate the good place for Radio signal

To maximize the distance of transmission, the ideal condition is Line-of-sight (LOS) between the Sigfox sensor and Base station. In real life, there may be no LOS condition. However, the Sigfox sensor still communicate with Base station, but the distance will be reduced significantly.

ATTENTION:

DO NOT install the Sigfox sensor or its antenna inside a completed metallic box or housing, because RF signal can not pass through metallic wall. The housing is made from Non-metallic materials like plastic, glass, wood, leather, concrete, cement…is acceptable.

WARNINGS:

Prepare the professional tools for installation. The inappropriate tools may cause damage to the sensor.

DANGER:

1. The installer need to be equipped with full Safety gears during installation, such as safety glasses, safety shoes, safety cloths, safety mask...Please follow the safety instructions of the installation site;

2. The installer must be qualified for this installation job;

3. The installer must be permitted by Site's owner for performing the installation;

4. The working conditions in hazardous areas (toxic gases, explosive atmosphere, high pressure, high temperature...) must be highly attention and follow the site's owner instruction strictly.

DO NOT OPEN THE COVER OR REPLACE/INSERT BATTERIES IN THE HAZADOUS AREAS

7.2 Battery installation

Steps for battery installation:

DANGER:

DO NOT REPLACE BATTERY AT HAZARDOUS LOCATION!

DO NOT OPEN THE COVER AT HAZARDOUS LOCATION!

ONLY OPEN COVER AND REPLACE BATTERY IN SAFE AREA!

Step 1: Turn the front cover of the sensor counter-clockwise;

Step 2: Carefully take out the front cover of the sensor

Step 3: Insert the type AA battery, please take note the polarity of battery

ATTENTION:

REVERSED POLARITY OF BATTERIES IN 10 SECONDS CAN DAMAGE THE SENSOR CIRCUIT!!!

Step 4: Turn the front cover of the sensor clockwise to close fully.

NOTES:

Using 2mm hex key to lock the cover to prevent the unattended opening.

7.3 Sigfox node connection

WSSFCEX-EVC can connect to any electronic volume corrector via Mercury protocol.

Configuration information for EVC

RS232 Connection: auto-baurate or 9600

Instrument access code: 33333

Temperature Unit: °C

Model requirements: Honeywell / Mercury Mini - Max

8. Troubleshooting

| No. | Phenomena | Reason | Solutions |

| 1 | Node does not send RF to base station periodically, LED does not blink |

|

|

| 2 | Node does not send RF to base station according to the alarm, LED does not blink |

|

|

| 3 | Node does not send RF to base station when activated by the magnetic switch, LED does not blink |

|

|

| 4 | Node has blinked LED when sending RF but the base station cannot received |

|

|

| 5 | Node has sent RF but the LED does not blink |

|

|

| 6 | The value of the sensor is 0 |

|

|

| 7 | The node does not send RF and the RF module is hot |

|

Warranty or replacement |

| 8 | RSSI is weak and often loses data |

|

|

9. Support contacts

|

Manufacturer Daviteq Technologies Inc Email: info@daviteq.com | www.daviteq.com

|

Distributor in Australia and New Zealand Templogger Pty Ltd Tel: 1800 LOGGER Email: contact@templogger.net |

|

|

|

No Comments