USER GUIDE FOR SIGFOX ULTRASONIC LEVEL SENSOR FOR TRASH BIN WSSFC-ULA

THIS IS OBSOLETE MANUAL

Please access https://www.iot.daviteq.com/wireless-sensors for updated manual

| WSSFC-ULA -MN-EN-01 |

DEC-2020 |

This document is applied for the following products

| SKU | WSSFC-ULA | HW Ver. | 1.1 | FW Ver. |

1.0

|

| Item Code |

WSSFC-ULA-8-01 |

Sigfox Ultrasonic Level Sensor for Trash bin, Internal antenna, 4500mm range, Type AA battery 1.5VDC, IP67, RC1 zone | |||

| WSSFC-ULA-9-01 | Sigfox Ultrasonic Level Sensor for Trash bin, Internal antenna, 4500mm range, Type AA battery 1.5VDC, IP67, RC2-RC4 zones | ||||

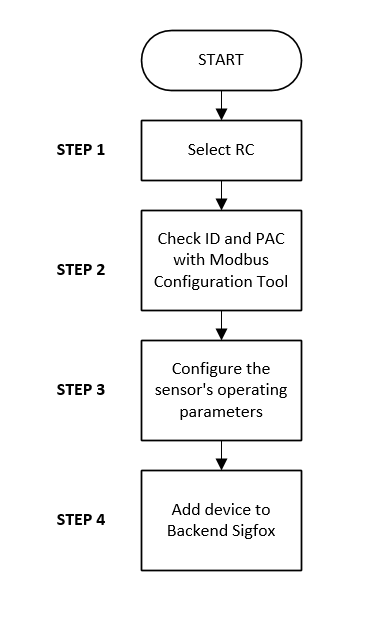

0. Configuration Check List

|

Step 1: Overview check |

|

|

Refer to section 5 for details |

|

STEP 1: Select RC |

|

|

1. Select RC zone using Modbus Configuration Cable |

RC zones selection 1, 2, 4 is RCZ1, RCZ2, RCZ4 (refer to register address 270)

|

| 2. Select RC zone | Refer here |

|

Use Modbus Configuration Cable to read the ID and PAC values |

Refer to register address 8 and 10 (DEC) |

|

STEP 3: Configure the sensor's operating parameters |

|

| Configure parameters like cycle send data, alarm, a, b,... | Refer to the configuration section using the Modbus Configuration Cable |

|

STEP 4: Add device to Backend Sigfox |

|

| refer to section 5.4 for details |

1. Functions Change Log

| HW Ver. | FW Ver. | Release Date | Functions Change |

| 1.1 | 1.0 | DEC-2020 |

2. Introduction

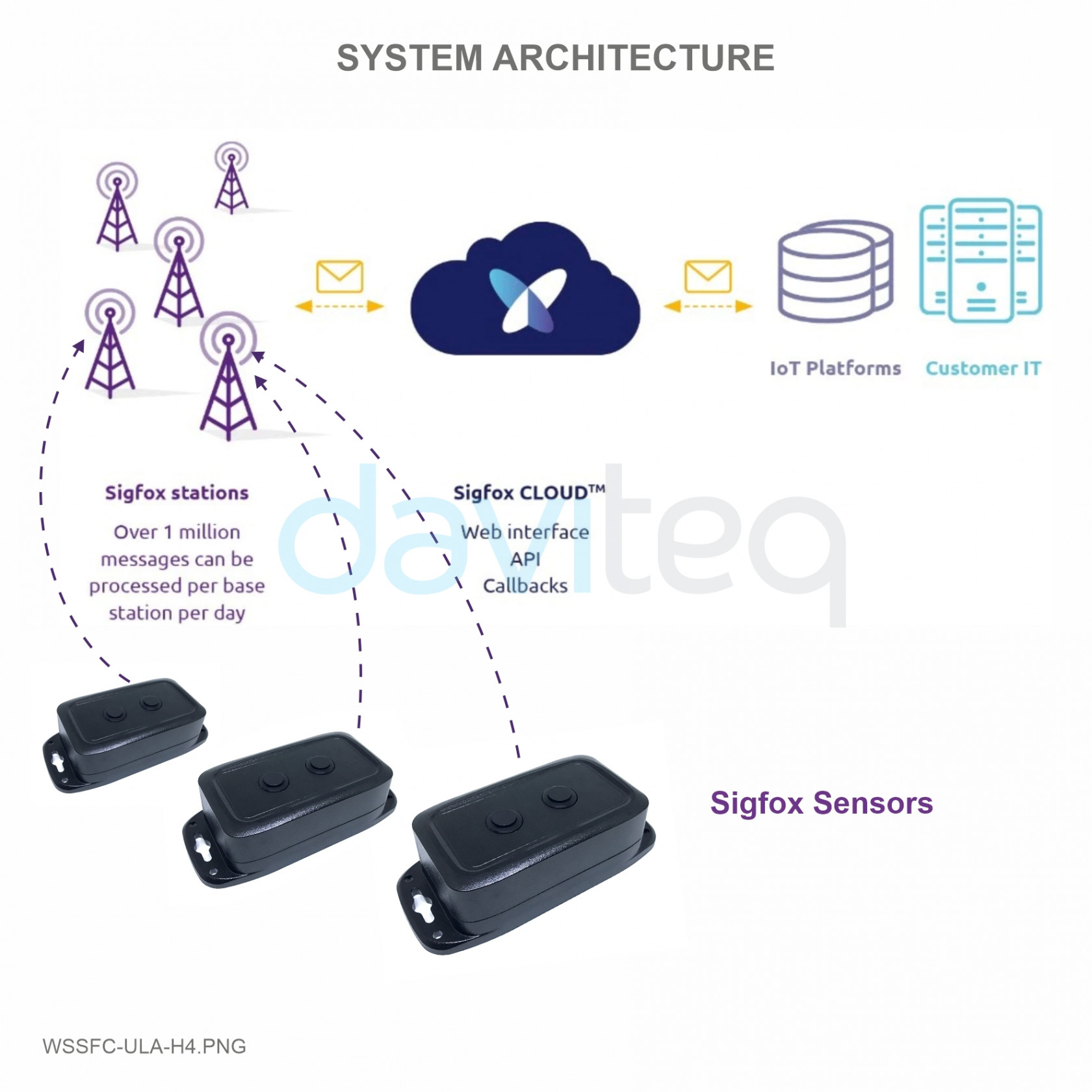

The WSSFC-ULA is a Sub-GHz wireless sensor that uses ultrasonic technology to measure trash bin levels. With advanced digital signal processing technology, the sensor can eliminate unwanted reflected ultrasonic waves. The sensor can be used for trash cans with openable lids where the measured value is not affected during the opening and closing. The sensor is designed for IP68 Standard, which can be used both indoors and outdoors. With Ultra-low Power design and smart firmware allow the sensor can last up to 10 years with 02 x AA-type batteries (depends on configuration). WSSFC-ULA can support all regions of Sigfox network in over the World, RC1, RC2, RC4.

The sensor is used to monitor the level of garbage in the trash cans in Office buildings, Hospitals, Schools, Factories... and also for public trash cans of Smart City.

3. Specification

| Sensor SPECIFICATION: | |

| Measurement technology | Dual ultrasonic sensor |

| Measuring range | 30 .. 4500 mm |

| Resolution & Accuracy | 1.0mm, +/- 10mm |

| Sampling and transmission rates | Configurable from 30 seconds to 3600 seconds |

| Working temperature | -15 .. +60°C |

| Working humidity | 0 .. 95% RH, non condensing |

| Sigfox SPECIFICATION: | |

| Sigfox zones | select RC2-RC4 or RC1 |

| Antenna | Internal Antenna 2dbi |

| Battery | 02 x AA Type 1.5VDC, working time up to 10 years (depends on configuration) |

| RF Module complies to | CE, FCC, ARIB |

| Working temperature | -15°C..+60°C (with AA L91 Energizer) |

| Dimensions | H180xW50xD40 |

| Net-weight | 250 grams |

| Housing | Poly-carbonate, IP68 |

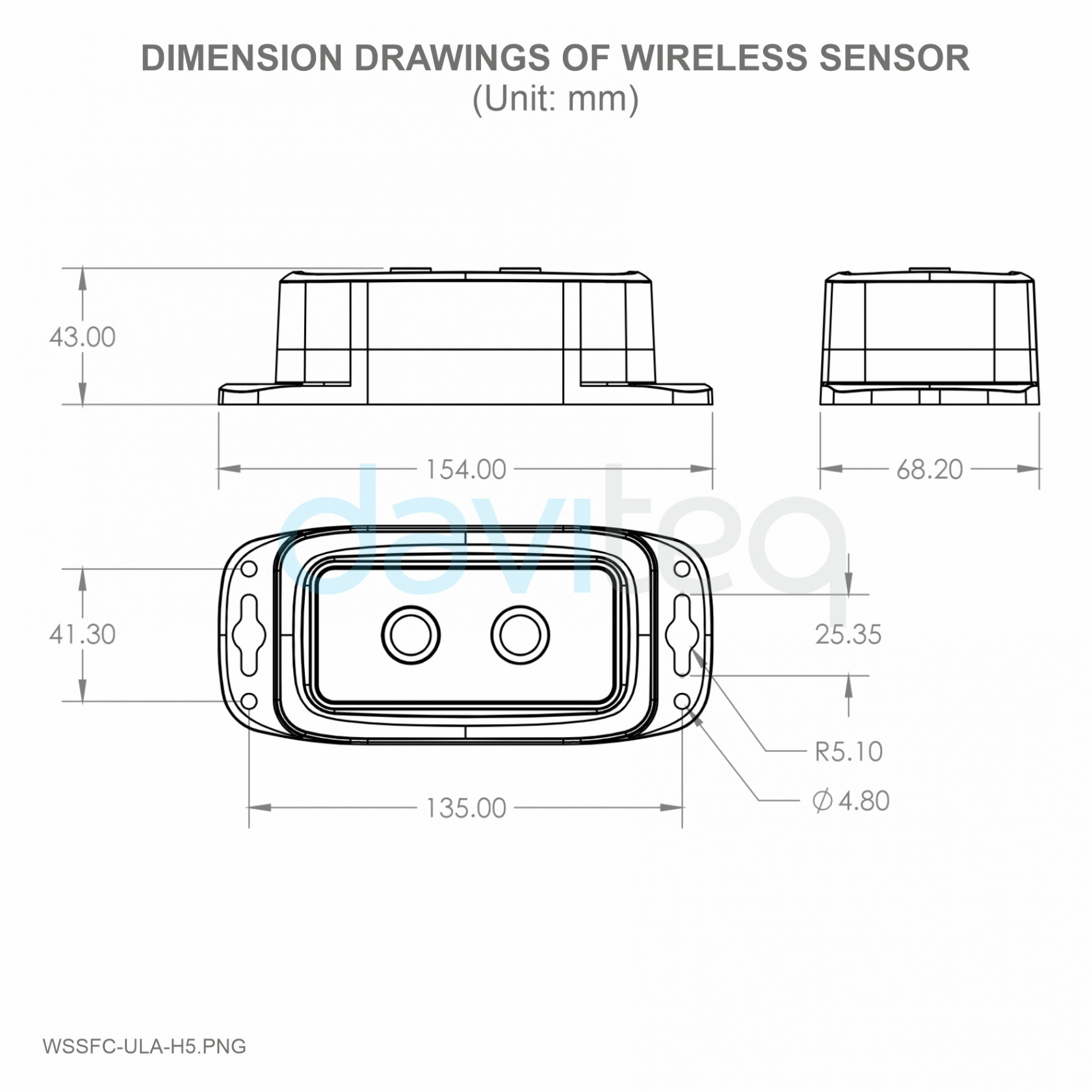

4. Dimensions

5. Scope of delivery

- Sigfox ultrasonic level sensor

- Magnet key

- BTP1- PARTSKIT-ULA

6. Operation Principle

Upon power on, the Sigfox node has 60 seconds to wait for off-line configuration (via cable with ModbusRTU protocol).

After that, Sigfox node will send the first message to Base station.

Then during the operation, there are 03 cases of sending data to base station:

1. When the sensor sampling time interval is reached, the Sigfox node will read the data from Input or sensor and performing the calculation. After that it will check calculated value with alarm thresholds. If the calculated was out off the threshold values (Lo or Hi), called alarm, and the number of times of alarm did not pass the limit of number of alarms, then it will send data to Base station immediately;

NOTE:

Once sending the data to base station by this alarm event, the timer of sending time interval will be reset;

2. When the sending time interval is reached, it will send data to Base station immediately, regardless of value;

3. By using the magnet key, the Sigfox node can be triggered to send data to base station immediately. There will be a beep sound from the buzzer meaning the data has been sent.

NOTE:

Once sending the data to base station by the magnet key, the timer of sending time interval will be reset;

The shortest time interval between the two manual triggers is 15s. if shorter than 15s, there will be no data sending and you will not hear the beep sound.

6.1 LED meaning

- RC1: RED colour

- RC2: GREEN colour

- RC4: BLUE colour

6.2 Magnet Key Function

6.2.1 Menu configuration

There are 3 configuration menus: tx_repeat, downlink_flag, radio configuration.

6.2.1.1 tx_repeat

Hold the magnet key 2s -> When the Red LED is on, it means entering the tx_repeat configuration menu. Then release to configure it.

Light touch to configure. After touching if the Red LED flashes once, tx_repeat = 0 (send 1 time). After touching if the Red LED blinks twice, it is tx_repeat = 1 (send 3 times).

6.2.1.1 downlink_flag

Hold the magnet key 5s -> When the Green LED is on, it means entering the downlink_flag configuration menu. Then release to configure it.

Light touch to configure. After touching if the Green LED flashes once, it is downlink_flag = 0 (downlink is not allowed). After touching if the Red LED blinks twice, it is downlink_flag = 1 (downlink is allowed).

6.2.1.1 radio configuration

Hold the magnet key 10s -> Blue LED is on, it means entering the Radio Configuration menu. Then release to configure it.

Light touch to configure. After touching if the Blue LED blinks once, it is Radio Configuration = 1. After touching if the Blue LED flashes twice, it is Radio Configuration = 2. After pressing if the Blue LED flashes 4 times, it is Radio Configuration = 4.

6.2.2 Exit the menu:

There are 3 ways to exit the menu:

- Hold for 3s, the LED turns off to exit the menu;

- Wait 30 seconds, then exit the menu;

- Take out the battery, it all starts over (outside the menu)).

6.3 RC technical details

The RF transmit power will be automatically set as the max value as allowed by the Zone.

Sigfox Radio Configuration (RC) defines the radio parameters in which the device shall operate: Sigfox operating frequencies, output power, spectrum access mechanism, throughput, coexistence with other radio technologies, etc.

Each radio configuration includes 4 uplink classes: 0u, 1u, 2u, and 3u.

The Sigfox network globally works within the ranges from 862 to 928 MHz. But not all RCs require such a wide range of operation.

| RC1 | RC2 | RC4 | |

|---|---|---|---|

| Uplink center frequency (MHz) | 868.130 | 902.200 | 920.800 |

| Downlink center frequency (MHz) | 869.525 | 905.200 | 922.300 |

| Uplink data rate (bit/s) | 100 | 600 | 600 |

| Downlink data rate (bit/s) | 600 | 600 | 600 |

| Sigfox recommended EIRP (dBm) | 16 | 24 | 24 |

| Specifics | Duty cycle 1% * | Frequency hopping ** | Frequency hopping ** |

* Duty cycle is 1% of the time per hour (36 seconds). For an 8 to 12 bytes payload, this means 6 messages per hour, 140 per day.

** Frequency hopping: The device broadcasts each message 3 times on 3 different frequencies. Maximum On time 400 ms per channel. No new emission before 20 s.

*** Listen Before Talk: Devices must verify that the Sigfox-operated 200 kHz channel is free of any signal stronger than −80 dBm before transmitting.

Sigfox’s high limit EIRP recommendation is included in each column although regulations sometimes allow for more radiated power than the Sigfox recommendation.

Sigfox’s recommendation is set to comply with the Sigfox technological approach of:

- Low current consumption

- Balanced link budget between uplink and downlink communication

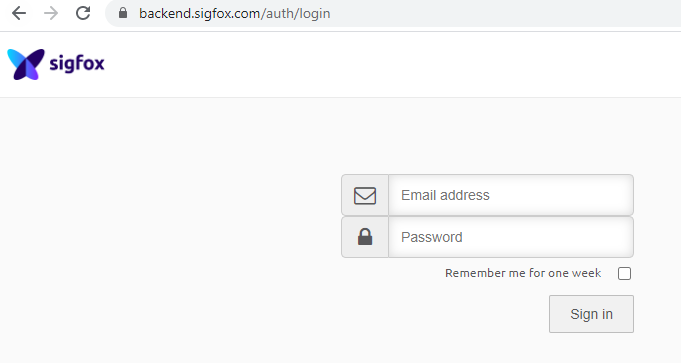

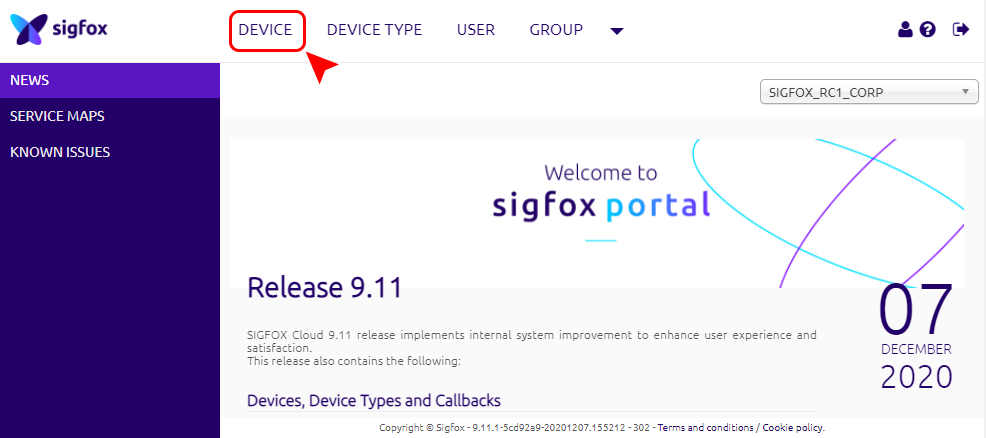

6.4 Add a device to the Backend Sigfox

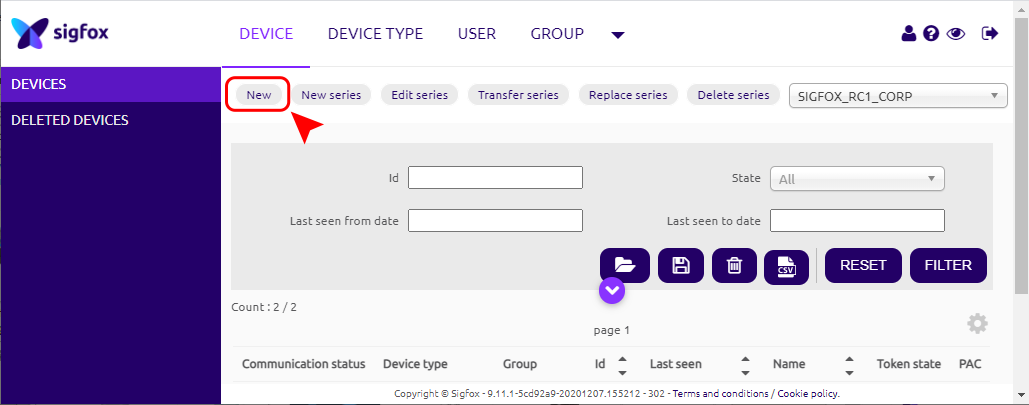

Step 1: Log in to the sigfox backend website

Step 2: Click on Device

Step 3: Click New → Select a group

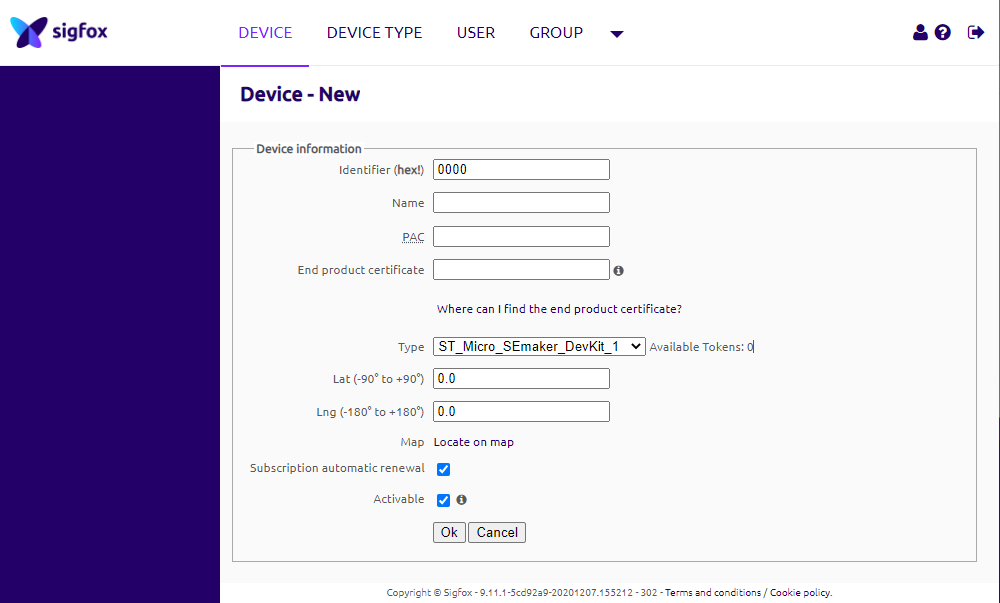

Step 4: Fill in the required information

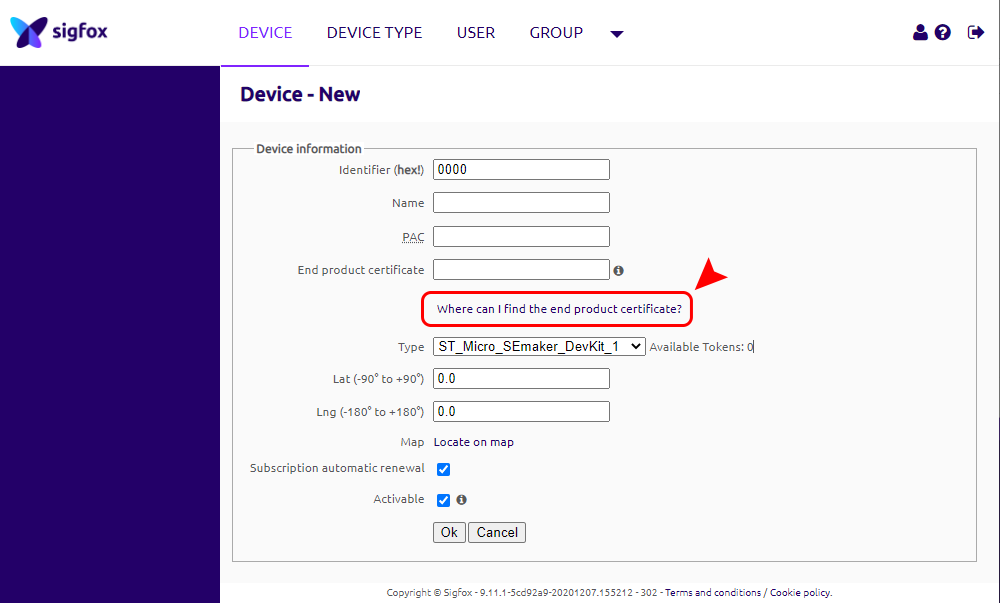

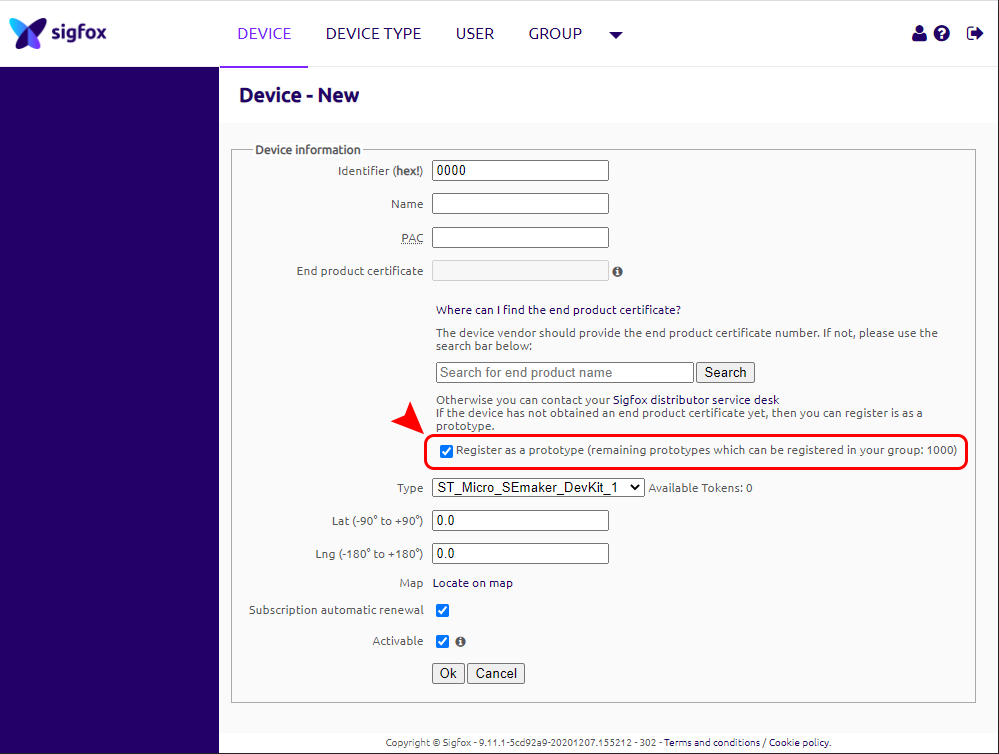

Note: Some of our products may not have end product certification in time, to add the product to Backend Sigfox please follow the steps below.

Click on the text as shown below

Check the box as shown below to register as a prototype

6.5 The Effective Detection Range

6.6 Process of measurement

6.6.1 Measurement principle of Sigfox Sensor

When the sensor sampling time interval is reached, for example 2 minutes, the Sigfox node will wake up and switch ON the power supply to supply the energy to external sensor to start the measurement. Depends on the type and characteristic of external sensor, the sensor will take a certain time to finish the measurement.

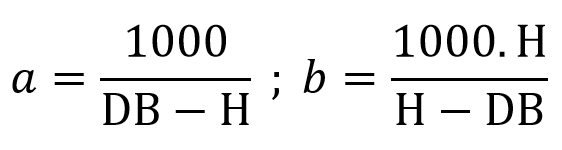

Once reading the value, it can be scaled to any engineering value by the following formula:

Y = aX + b

Where:

-

-

- X: the raw value from sensor

- Y: the calculated value will be sent to Sigfox base station in the payload data.

- a: constant (default value is 1)

- b: constant (default value is 0)

-

So, if there is no user setting for a and b ==> Y = X

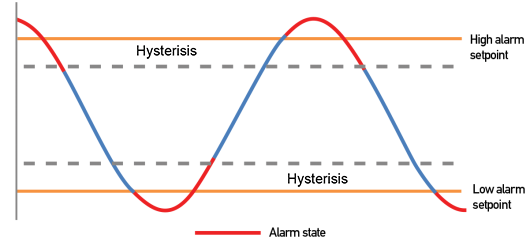

The Y value will be compared with Lo and Hi threshold. Please refer below the graph of alarm processing.

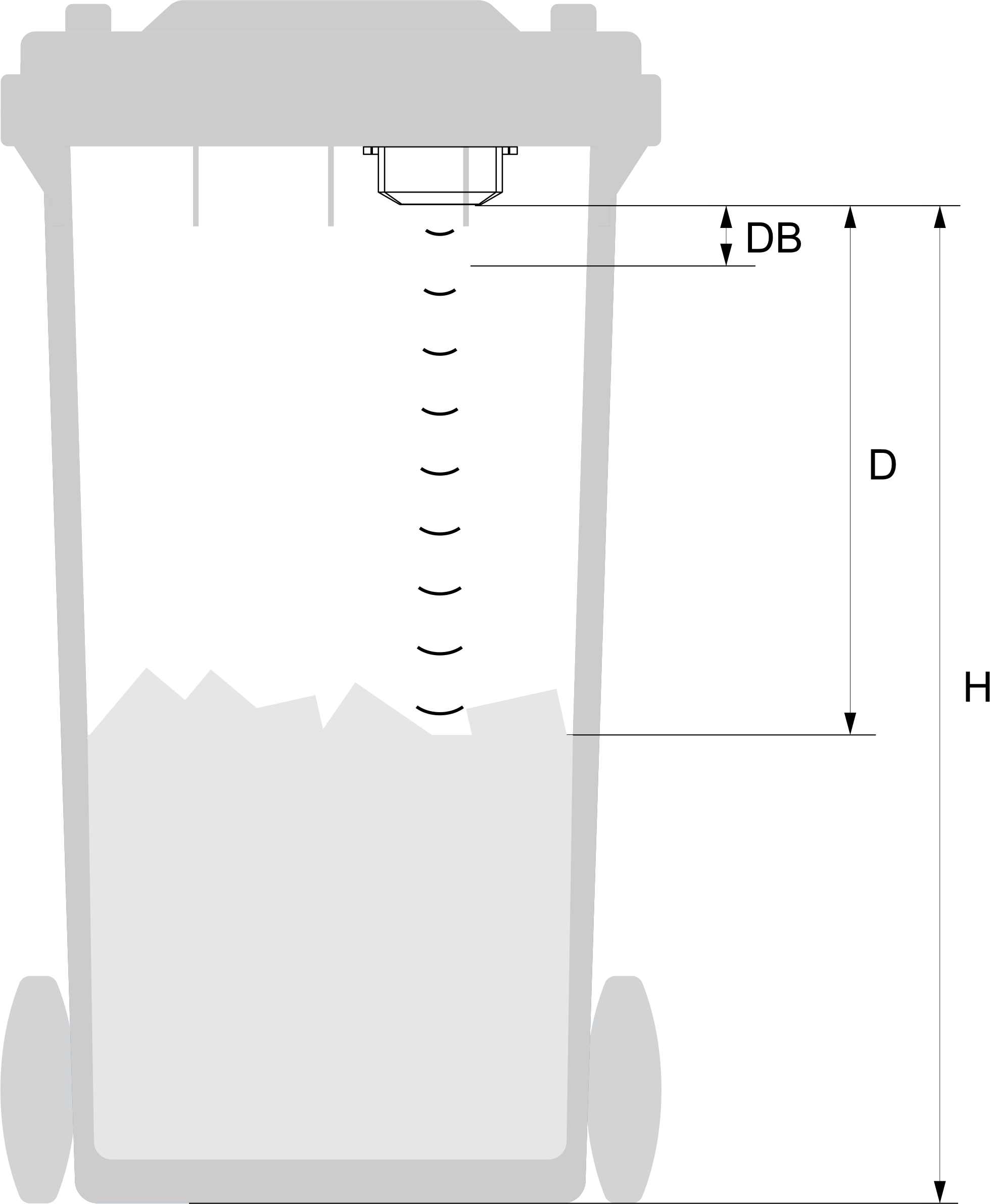

6.6.2 Calibration

Figure – Ultrasonic Level Transmitter Calibration

- DB: Dead band 0..300 mm (This is a short range in front of the ultrasonic sensor can not measure distances)

- H: Maximum measuring distance ( Span )

- D: Distance

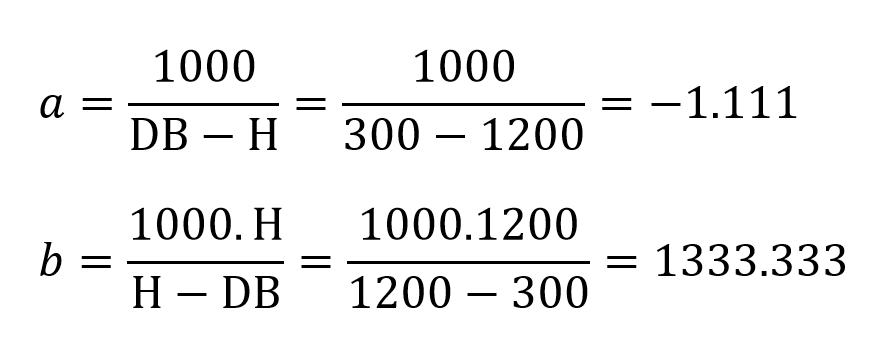

For example: Trash bin with maximum height to be measured 1200mm (H) and the maximum height to measure is 300mm (Recommended to install the lowest point that should be larger than the Deadband 300mm), then:

From here we can look up the trash level corresponding to the measured distance of the sensor by the formula: Y = aX + b.

Where: X is the measured distance (mm) and Y is the level (‰)

| Distance (mm) | Level (‰) |

| 300 | 1000 |

| 400 | 889 |

| 500 | 778 |

| 600 | 667 |

| 700 | 556 |

| 800 | 445 |

| 900 | 333 |

| 1000 | 222 |

| 1100 | 111 |

| 1200 | 0 |

Use the offline configuration tool to configure sigfox sensor. Write in the sensor the parameters a1 and b1.

Refer to Resigter table for more details.

6.7 Payload Data

|

Sensor type (1 byte) |

Status (1 byte) |

1 st - Parameter (2 bytes) |

2nd - Parameter (2 bytes) |

| Data | Size (byte) | Bit | Format | Meaning |

|

Sensor type |

1 |

all |

Uint8 |

Sensor type = 0x0E means ULA sensor |

|

Status: battery level

|

1 |

Bit 7 and 6 |

Uint8 |

Battery capacity in 04 levels

|

|

Status: error |

|

Bit 5 and 4 |

|

Node status

|

|

Status: alarm 1 |

|

Bit 3 and 2 |

|

Alarm status of 1st - Parameter (Y1 value)

|

|

Status: alarm 2 |

|

Bit 1 and 0 |

|

Alarm status of 2nd - Parameter (Y2 value)

|

|

1st - Parameter |

2 |

all |

Uint16 |

Y1 value: Level (x 0.1%) |

|

2nd - parameter |

2 |

all |

Uint16 |

Y2 value: Distance(mm) |

7. Offline configuration

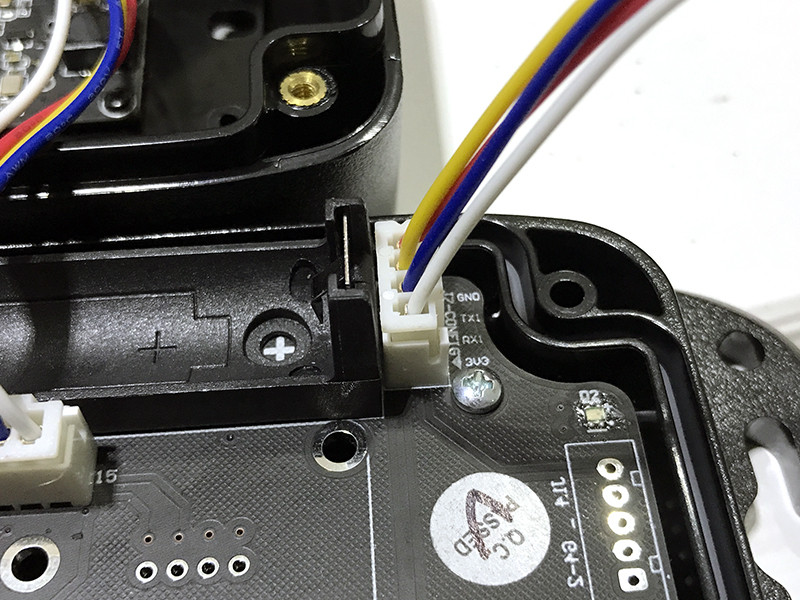

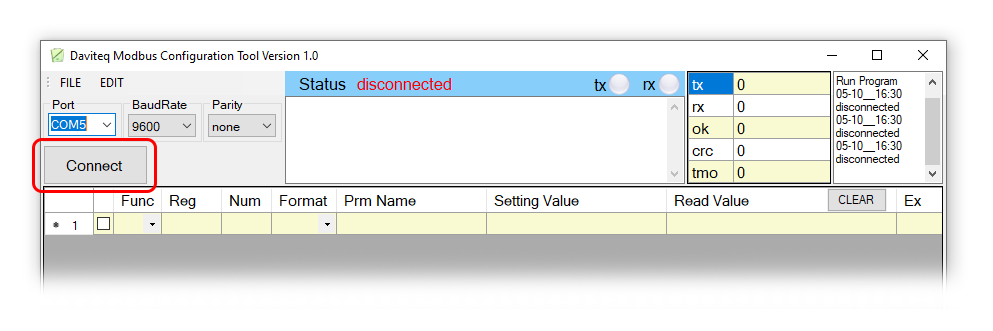

Using the configuration cable to connect to the sensor as below picture.

Serial port configuration on computer: 9600 baud, None parity, 1 stop bit.

Reading data by Function 3.

Writing data by Function 16.

During connection with Modbus configuration tool, the Sigfox node will send all data in realtime: Battery, Battery level, Vref, Button status, reed switch status, PCB temperature, Measured value, alarm status.

Step to configure & check data:

NOTE:

The Modbus configuration can be done in the first 60s after power up the Sigfox node. After 60s, if user can not finish the configuration, user need to reset the power of Sigfox node again, by removing battery in at least 15s.

Step 1: Install the Modbus Configurator Software in the link below

https://filerun.daviteq.com/wl/?id=qK0PGNbY1g1fuxTqbFW9SXtEvCw7bpc6

How to use the Modbus configuration software

Step 2: Plug the configuration cable to Computer via USB port;

Step 3: Open the housing with phillips screwdriver to unscrew M3 screws at the side of the housing

Step 4: Plug the connector to the configuration port;

Step 5: Import the configuration file by importing the csv file: Go to MENU: FILE / Import New / => select the file with name CONFIGURATION TEMPLATE FILE FOR SIGFOX WSSFC-ULA.csv (in the link below). Then click Connect;

CONFIGURATION TEMPLATE FILE FOR SIGFOX WSSFC-ULA.csv

Here is the table of Data will be read by Modbus tool

| Modbus Register (Decimal) | Modbus Register (Hex) | Function Code | # of Registers | Description | Range | Default | Format | Property | Comment |

| 0 | 0 | 3 | 2 | device info | string | Read | Product name | ||

| 2 | 2 | 3 | 4 | firmware version | 1.0 | string | Read | ||

| 6 | 6 | 3 | 2 | hardware version | 1.0 | string | Read | ||

| 8 | 8 | 3 | 2 | device ID | hex | Read | Product ID | ||

| 10 | A | 3 | 4 | device PAC | hex | Read | Product PAC | ||

| 14 | E | 3 | 1 | sen_type | 1-255 | uint16 | Read | Sensor or Input Type | |

| 15 | F | 3 | 1 | batt level | 0-3 | uint16 | Read | Battery level | |

| 16 | 10 | 3 | 1 | err_status | 0-1 | uint16 | Read | Sensor error code | |

| 17 | 11 | 3 | 1 | prm1 alm_status | 0-2 | uint16 | Read | Alarm status of 1st parameter | |

| 18 | 12 | 3 | 1 | prm2 alm_status | 0-2 | uint16 | Read | Alarm status of 1st parameter | |

| 19 | 13 | 3 | 2 | prm1 value | float | Read | 1st calculated value | ||

| 21 | 15 | 3 | 2 | prm2 value | float | Read | 2nd calculated value | ||

| 23 | 17 | 3 | 1 | batt % | 10%, 30%, 60%, 99% | uint16 | Read | Battery % | |

| 24 | 18 | 3 | 2 | batt volt | 0-3.67 vdc | float | Read | Battery Voltage | |

| 26 | 1A | 3 | 2 | temp | oC | float | Read | RF module temperature | |

| 28 | 1C | 3 | 1 | vref | 0-3.67 vdc | uint16 | Read | Vref of RF Module | |

| 29 | 1D | 3 | 1 | btn1 status | 0-1 | uint16 | Read | Button status, 0: released, 1: pressed | |

| 30 | 1E | 3 | 1 | btn2 status | 0-1 | uint16 | Read | Reedswitch status, 0: opened, 1: closed |

Here is the table for Configuration:

| Modbus Register (Decimal) | Modbus Register (Hex) |

Function Code (Read) |

Function Code (Write) |

# of Registers | Description | Range | Default | Format | Property | Comment |

| 256 | 100 | 3 | 16 | 1 | modbus address | 1-247 | 1 | uint16 |

Read/ Write |

Modbus address of device |

| 270 | 10E | 3 | 16 | 1 | Radio Configuration | 1-6 | 4 | uint16 |

Read/ Write |

RC zones selection 1, 2 ,4 is RCZ1, RCZ2, RCZ4 |

| 271 | 10F | 3 | 16 | 1 | tx_power | 20 | int16 |

Read/ Write |

RF Tx power | |

| 272 | 110 | 3 | 16 | 1 | tx_repeat | 0-1 | 1 | uint16 |

Read/ Write |

Number of repeat, 0: 1 time, 1: 3 repeats |

| 273 | 111 | 3 | 16 | 1 | downlink_flag | 0-1 | 1 | uint16 |

Read/ Write |

1: enable Downlink, 0: disable Downlink (Fw v1.0 hasn't got Downlink function) |

| 274 | 112 | 3 | 16 | 2 | cycle_send_data | 3600 | uint32 |

Read/ Write |

Data sending cycle, in seconds | |

| 276 | 114 | 3 | 16 | 2 | spare | Spare for future | ||||

| 278 | 116 | 3 | 16 | 1 | alarm_limit | 0 | uint16 |

Read/ Write |

Limit number of alarm sending in 24h | |

| 279 | 117 | 3 | 16 | 1 | spare | Spare for future | ||||

| 280 | 118 | 3 | 16 | 2 | sensor1: sampling_rate | 120 | uint32 |

Read/ Write |

Sensor/Input 1 sampling rate, in seconds | |

| 282 | 11A | 3 | 16 | 2 | sensor1: calc_time | 500 | uint32 |

Read/ Write |

Measurement time of sensor/input 1, in ms | |

| 288 | 120 | 3 | 16 | 2 | prm1: a | 1 | float |

Read/ Write |

Constant a for scaling measured value 1 | |

| 290 | 122 | 3 | 16 | 2 | prm1: b | 0 | float |

Read/ Write |

Constant b for scaling measured value 1 | |

| 294 | 126 | 3 | 16 | 2 | prm1: High threshold | 100000 | float |

Read/ Write |

Hi Threshold for calculated value 1 | |

| 296 | 128 | 3 | 16 | 2 | prm1: High Hysteresis | 10000 | float |

Read/ Write |

Hysterisis for Hi for calculated value 1 | |

| 298 | 12A | 3 | 16 | 2 | prm1: Low threshold | 0 | float |

Read/ Write |

Lo Threshold for calculated value 1 | |

| 300 | 12C | 3 | 16 | 2 | prm1: Low Hysteresis | 10000 | float | Read/Write | Hysterisis for Lo for calculated value 1 | |

| 302 | 12E | 3 | 16 | 2 | prm1: High cut | 100000 | float |

Read/ Write |

High cut value for calculated value 1 | |

| 304 | 130 | 3 | 16 | 2 | prm1: Low cut | 0 | float |

Read/ Write |

Low cut value for calculated value 1 | |

| 306 | 132 | 3 | 16 | 2 | prm2: a | 1 | float |

Read/ Write |

Constant a for scaling measured value 2 | |

| 308 | 134 | 3 | 16 | 2 | prm2: b | 0 | float |

Read/ Write |

Constant b for scaling measured value 2 | |

| 312 | 138 | 3 | 16 | 2 | prm2: High threshold | 100000 | float |

Read/ Write |

Hi Threshold for calculated value 2 | |

| 314 | 13A | 3 | 16 | 2 | prm2: High Hysteresis | 10000 | float |

Read/ Write |

Hysterisis for Hi for calculated value 2 | |

| 316 | 13C | 3 | 16 | 2 | prm2: Low threshold | 0 | float |

Read/ Write |

Lo Threshold for calculated value 2 | |

| 318 | 13E | 3 | 16 | 2 | prm2: Low Hysteresis | 10000 | float |

Read/ Write |

Hysterisis for Lo for calculated value 2 | |

| 320 | 140 | 3 | 16 | 2 | prm2: High cut | 100000 | float |

Read/ Write |

High cut value for calculated value 2 | |

| 322 | 142 | 3 | 16 | 2 | prm2: Low cut | 0 | float |

Read/ Write |

Low cut value for calculated value 2 |

8. Installation

8.1 Locate the good place for Radio signal

To maximize the distance of transmission, the ideal condition is Line-of-sight (LOS) between the Sigfox sensor and Base station. In real life, there may be no LOS condition. However, the Sigfox sensor still communicate with Base station, but the distance will be reduced significantly.

ATTENTION:

DO NOT install the Sigfox sensor or its antenna inside a completed metallic box or housing, because RF signal can not pass through metallic wall. The housing is made from Non-metallic materials like plastic, glass, wood, leather, concrete, cement…is acceptable.

8.2 Mounting

8.2.1 Installation method

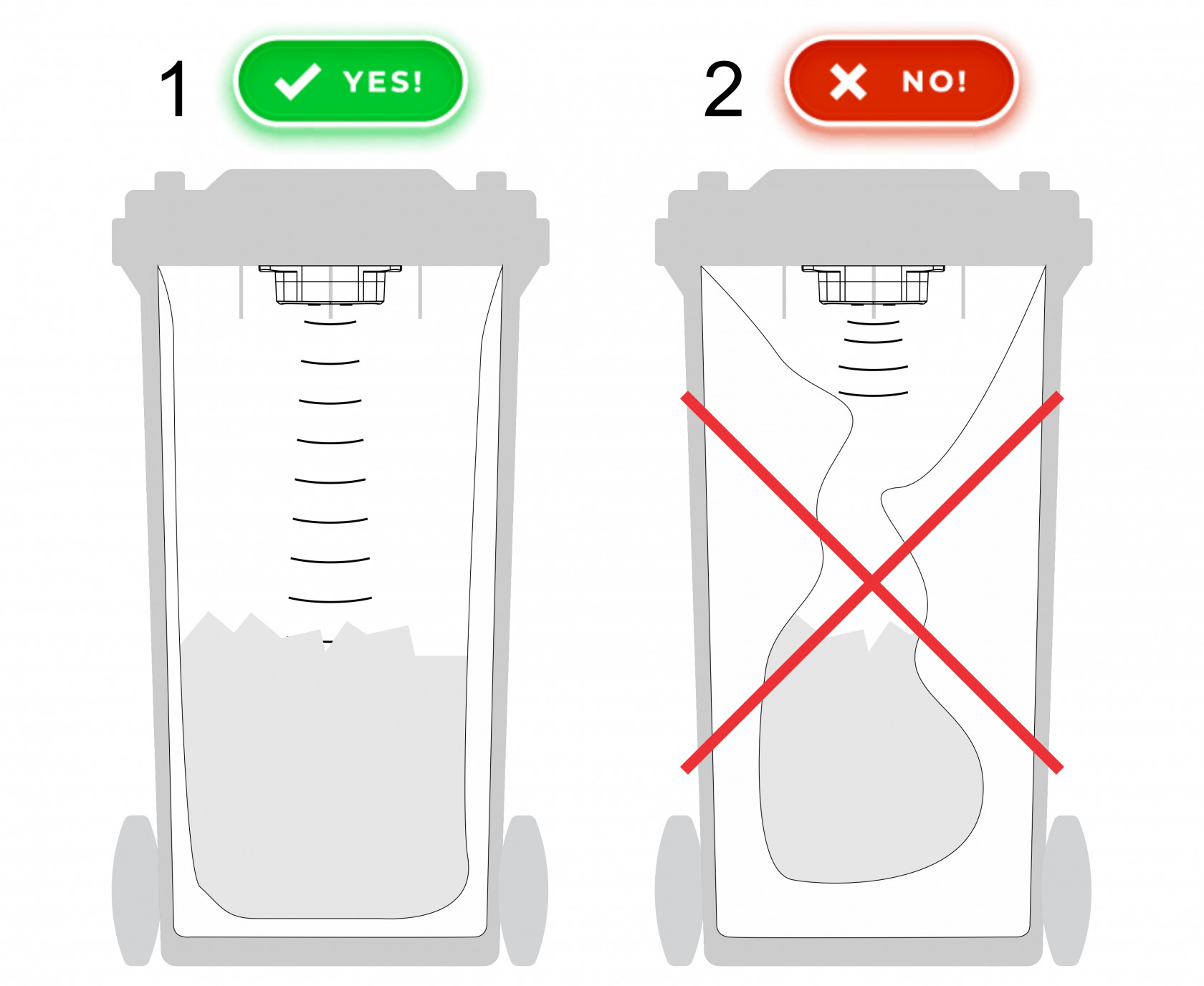

Mounting the sensor under the bottom and at the center of the trash bin lid

WARNING:

Avoid causing strong impact on the 2 probes on the sensor;

DO NOT install the sensor in complete metal trash bin because the signal can't transmit to the Gateway

Step 1: Determine the center of the trash bin

Step 2: Mounting the sensor under the trash bin lid by fasten the 4 screws that are included

8.2.2 Installation conditions

Align the sensor so that it is vertical to the solid surface (1)

When installing, do not let the plastic bag inflate too much to block the path of the sensor. (2)

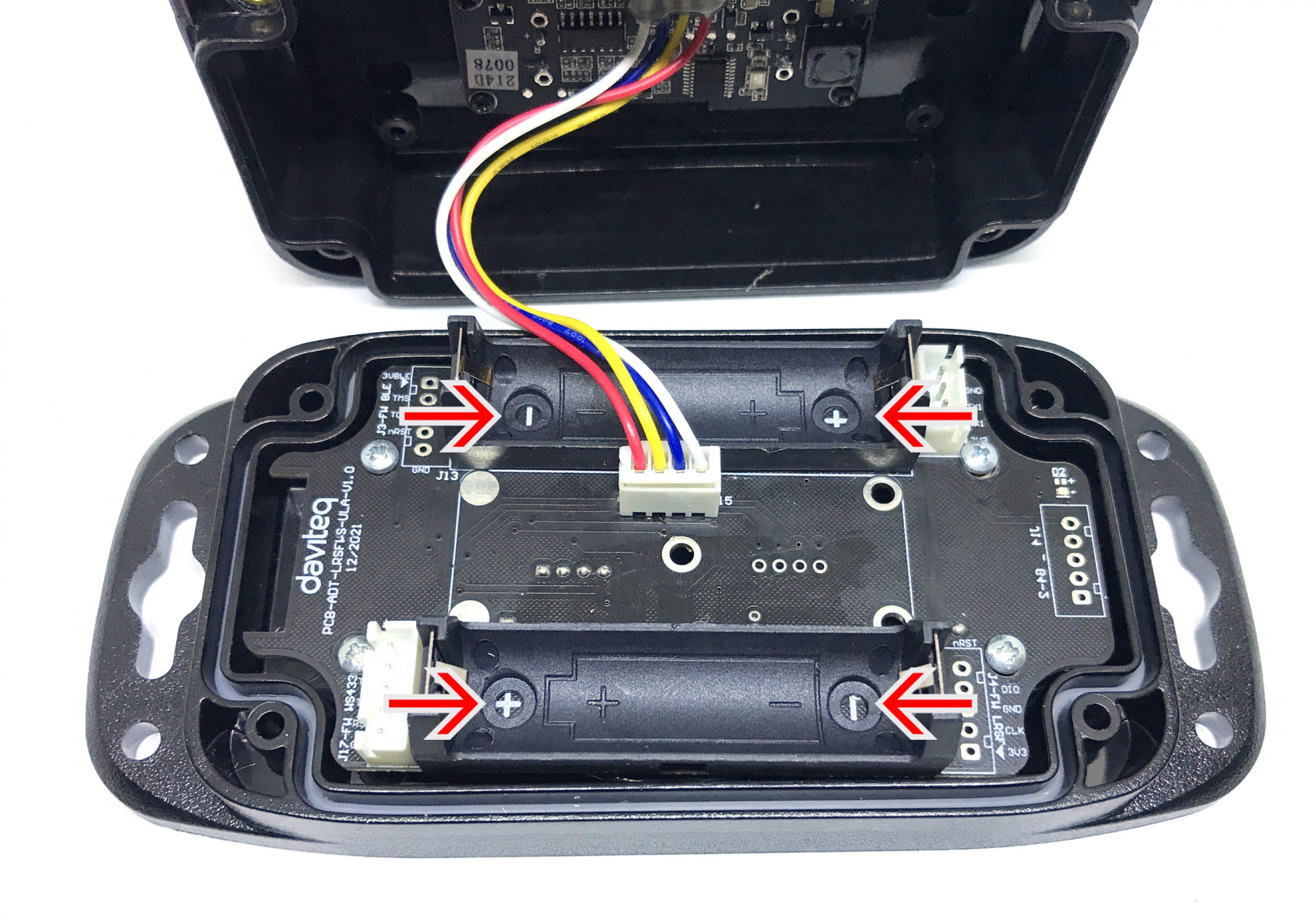

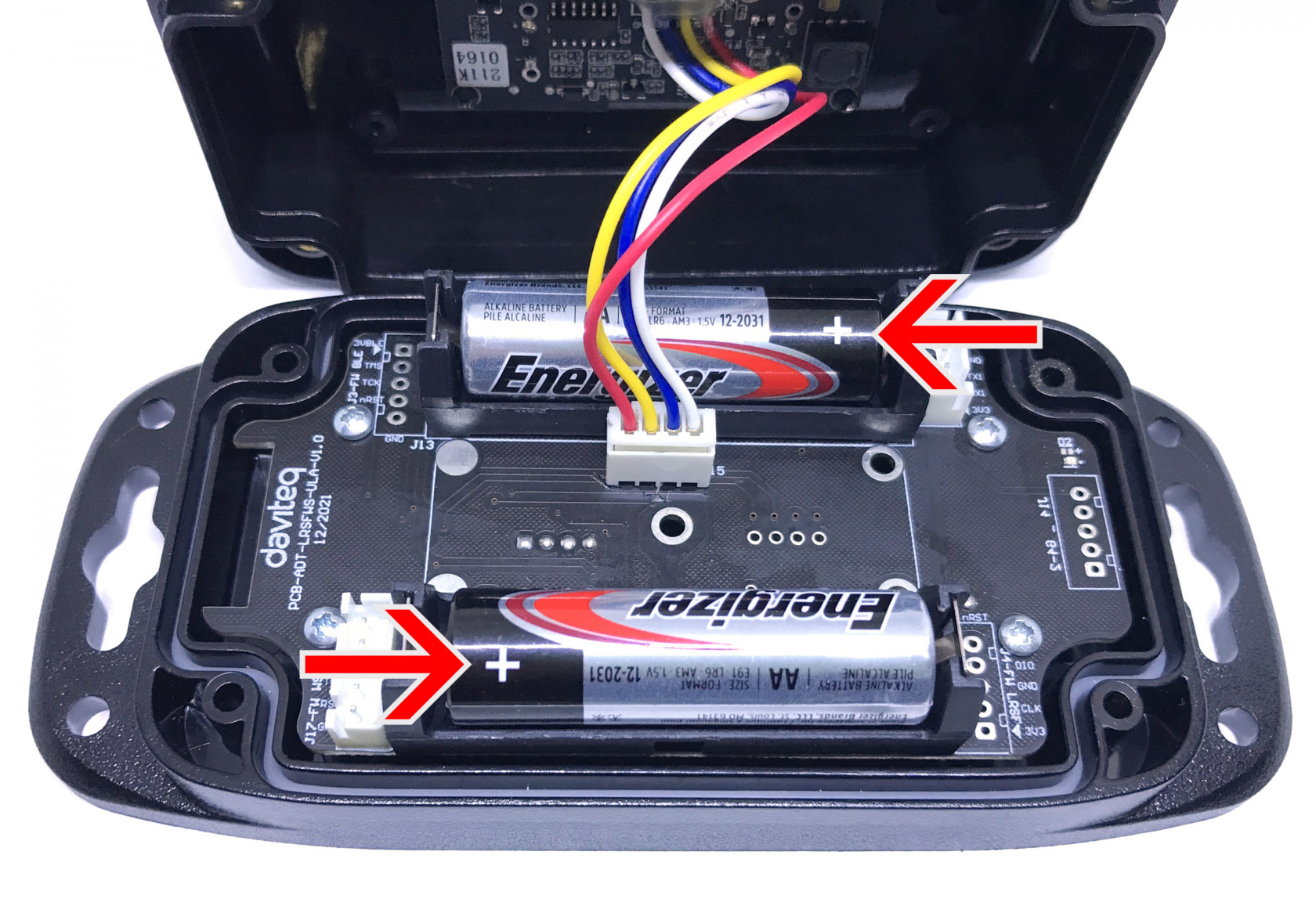

8.3 Battery installation

ENERGIZER L91 (recommended battery)

Steps for battery installation:

Step 1: Using Philips screw driver to unscrew 4 screws under the housing.

Step 2: Pull out the cover then insert 02 x AA 1.5VDC battery, please take note the poles of the battery.

ATTENTION: REVERSED POLARITY OF BATTERIES IN 10 SECONDS CAN DAMAGE THE SENSOR CIRCUIT !

Step 3: Insert the top plastic housing and locking the cover

9. Troubleshooting

| No. | Phenomena | Reason | Solutions |

| 1 | Node does not send RF to base station periodically, LED does not blink |

|

|

| 2 | Node does not send RF to base station according to the alarm, LED does not blink |

|

|

| 3 | Node does not send RF to base station when activated by the magnetic switch, LED does not blink |

|

|

| 4 | Node has blinked LED when sending RF but the base station cannot received |

|

|

| 5 | Node has sent RF but the LED does not blink |

|

|

| 6 | The value of the sensor is 0 |

|

|

| 7 | The node does not send RF and the RF module is hot |

|

Warranty or replacement |

| 8 | RSSI is weak and often loses data |

|

|

10. Support contacts

|

Manufacturer Daviteq Technologies Inc Email: info@daviteq.com | www.daviteq.com

|

Distributor in Australia and New Zealand Templogger Pty Ltd Tel: 1800 LOGGER Email: contact@templogger.net |

|

|

|

No Comments